Robotic Building. While, architecture and architectural production are increasingly incorporating aspects of non-human agency employing data, information, and knowledge contained within the (worldwide) network connecting electronic devices, the relevant question for the future is not whether robotic building may be implemented, but how robotic systems may be incorporated into building processes and physically built environments in order to serve and improve everyday life; how these systems may offer solutions for energy-efficient building, demand-driven production and operation, and efficient use of resources.

The RB session of the GSM #3 symposium aims to answer this question by critically reflecting on the achievements of the last decades in applications of robotics in architecture and furthermore outlining potential future developments and their societal implications. CNC Software: CAM Software, Simulators, Editors and Utilities. CNC Software: Digital Tooling for CNC Why Digital Tooling?

When I was learning to be a manual machinist, people used to say, "Budget as much for tooling as you do the machine. " Danged if they weren't right. In fact, if you wanted to be well tooled up (and what machinist wouldn't?) , you could even leave off your measuring tools from that budget and focus on workholding, fixturing, toolholding, cutters, and the like. Elisa Strozyk flexibiliza la madera hasta convertirla en un textil. Elisa Strozyk flexibiliza la madera hasta convertirla en un textil Cuando pensamos en diseño de autor, sabemos que nos enfrentamos a un producto único y especial.

ElasticSpace. Conor Coghlan. Corte Y Grabado Cnc En Madera, Aluminio, Acrílico, Pvc . - Quito - en Mercado Libre. Photos de la publication de Fab Lab... - Fab Lab Barcelona. Gmail – La messagerie avec espace de stockage gratuit de Google. Furniture.

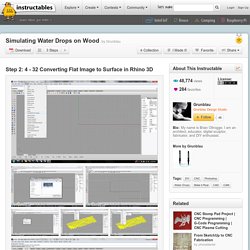

CREATIVEPRINT. المعلم - Foam Printer. Simulating Water Drops on Wood : 4 - 32 Converting Flat Image to Surface in Rhino 3D. Step 24: Open Rhino Step 25: Go to Surface>Heightfield from Image.

Navigate to Image saved in Step 23 and Select. Step 26: In the Top viewport, input the location for the start corner and type 12” for the length of the side. This is arbitrary, as we can scale it later. Step 27: In the Heightfield Dialogue box enter at least 200 X 200 for sample points and 1 for the depth. Step 28: Select the resulting suface and go to Analyze>Bounding Box and hit enter. Step 30: Using this bounding box, we will use Transform>Scale>Scale 1D to make the vertical height of the waves more appropriate. Step 31: Draw the stock (what you are milling out of) with the top face of the lower left hand corner at 0,0,0 and place your rippled surface within the stock.

Step 32: Draw a rectangle on the top of the stock that represents where you want to cut the piece out when it is done doing the surfacing. Wave. LIFT architects - Home - [Andrew Payne] It has been entirely too long since I last posted but that should change over the coming weeks as I've been working on some really amazing projects.

![LIFT architects - Home - [Andrew Payne]](http://cdn.pearltrees.com/s/pic/th/lift-architects-andrew-payne-109933702)

To kick things off, I thought I'd share a one week project that I developed to create a dimple halftone pattern on a surface using a custom build Grasshopper definition which writes the all of the G-code (for a ShopBot CNC mill) in real-time. I'll talk more about the fabrication setup below, but first... a little about the concept. Slicing & Waffles. THE IDEA. Waffle table. Geo cocktail table by Vito Selma. If you’re looking for a truly unique piece of furniture for your living room, we found it for you.

The Geo Cocktail Table is definitely an eye-catching piece that will instantly become the focal point of attention if any room, beating even the comfy sofa. Designed by Vito Selma, this unique piece of furniture features extraordinary lines and a very complex design. The interesting thing about this unusual cocktail table is, that you look at it from different angles, it changes its form and appearance. It can either look like a DNA table base or as a structure ready to fly. The base of the table has a very complex and dynamic design. Resultados de la Búsqueda de imágenes de Google de. Cultura libre y peer production: La era maker. En marzo de 1975 nace de forma oficial el Homebrew Computer Club, un pionero grupo de aficionados a los computadores en Silicon Valley, que comenzó a celebrar encuentros de garaje para compartir experiencias, conocimientos, diseños, fórmulas en un foro abierto de discusión en torno al mundo de la computación.

Fab Academy 2013. Máquina Fresadora Portátil. Una Máquina para Todo El Sensor Piezo Activo Roland (SPAR) transforma la máquina en un escáner 3D para escanear objetos en 3D y crear datos 3D.

Fab lab inventory. Fab Association - How to join - International Fab Lab Association. Robotic Fabrication Studio @ Hyperbody. If you like it, share it! MSc2 studio – 1:1 prototypes Whole studio project was initialized by Hyperbody research group at the Faculty of Architecture in TU Delft University . Jelle Feringa was leading the course and provided us with all needed infrastructure. Special thanks should also be given to guys from ROK office – Matthias Rippmann and Silvan Oesterle, they were kind enough to come to Delft and teach us how to make the best use of Rhino-Vault plugin , which they themselves develop. Chris Kievid was also very helpful in the assembly of the pavilion. Principles, applications and implications of digital fabrication. Archworkpenndesign's Profile. Inside Microsoft's model shop, where prototypes are printed in 3D.