Intel IoT. Video - Project Biped. ROFI bipedal robot by jdow. Step by step animated assembly instructions:projectbiped.com/prototypes/rofi/instructions printed part diagrams:projectbiped.com/prototypes/rofi/printed-parts non-printed parts list (vender and cost):docs.google.com/spreadsheet/ccc?

Key=0Ai_h1KTMNaWNdHktUVZlT3RZaGdzZm1tSXFrSm QzTmc#gid=0 Thanks to the CSULB EE class (building the first ROFI clone) for pointing out that some of the parts designed to work with the new MG966R horn style were too thick. A literature and practice review to develop sustainable business model archetypes. <div class="msgBox" style="margin-top:10px;"><span class="errMsg"><div>JavaScript is disabled on your browser.

Please enable JavaScript to use all the features on this page. </div></span></div><br /> Review University of Cambridge, Department of Engineering, Institute for Manufacturing, 17 Charles Babbage Road, Cambridge CB3 0FS, United Kingdom Received 19 December 2012, Revised 31 October 2013, Accepted 14 November 2013, Available online 4 December 2013 DOI: 10.1016/j.jclepro.2013.11.039 Get rights and content Open Access Highlights The literature and practice of sustainability innovation is vast but fragmented. This research seeks to develop a unifying research agenda. The paper introduces sustainable business model archetypes. These seek to serve as exemplars for sustainable business model innovation. Cosmo Wenman. Real metal finishes for objects printed in PLA, ABS, ceramics, and resin.

Vinyl too: - Aluminum - Bronze - Brass - Copper - Iron - Nickel Unlimited patina possibilities (right-click iamges to view full size) Portrait of Alexander the Great, -300 in Lost Bronze and Head of a horse of Selene in Epic Bronze. Portraits of Alexander the Great, -300, 1440, 1945 in Lost Bronze, Firenze, and Wrecked Iron. Portrait of Alexander the Great, -300 in Lost Bronze. Portrait of Alexander the Great, 1440 in Firenze. 100% Warp-Free MakerBot 3D Printing : There You Have It...100% Warp-Free and Curl-Free Free 3D Printing! Mechanical Design for 3D Printing - The Adventures of Eiki Martinson. There's a great deal of hype surrounding the technology of additive manufacturing or 3D printing just now.

I'm sure my audience has heard things like “It'll make whatever you can imagine”, to which the appropriate answer is, after Han Solo, “I don't know, I can imagine quite a bit.” In truth, like any manufacturing technique, 3D printing is ideal for some things, marginal for others, and completely unworkable for a few; but with a bit of knowledge about the limitations of your particular additive process and some clever workarounds, you can expand the capabilities of the machine and avoid the inevitable hype hangover. Here I've collected a few modest contributions to that: some common mechanical components and structural features that hopefully will be of use to your 3D printing projects. Screw Threads. AstroPrint launches on Kickstarter, now you can slice, store and 3D print from smartphone.

May 20, 2014 3Dagogo, a California-based startup just launched a Kickstarter campaign today for their new product 'AstroPrint'.

The AstroPrint platform allows you to use any smartphone or tablet as an effective interface to control your 3D printers. AstroPrint is a software platform that performs all the functions of your printer controllers and slicers. The AstroPrint platform consist of two parts: The AstroBox is a small stylish box with a laser cut acrylic case that connects to your 3D printer via a USB cable.

All you need to do is to simply plug your printer's USB cable into the AstroBox. The second part is AstroPrint.com, which uses your free account to slice, organize, and store your designs in the cloud.

Major Blogs. Materials. Remote Mount Hot End. HPX1: Single Extruder. Catalogue. 3D Printing Service i.materialise. Online 3D Printer store in India. Reprap kits, filaments, electronics, spares, kits & more. The Adventures of Eiki Martinson. 3d printers. How 3-D Printing Startups Are Shaping the Future. "10-22-38 Astoria" -- that was the message written on the first photocopied page, which was produced in 1938.

In the 50 years that followed, Xerox was born, a trillion-dollar industry developed around document duplication, every business got a copier (if not two) and home printers became able to reproduce pages. But today, with 3-D printing, we can print a lot more than just words and images. With the emergent technology, any desktop computer can output objects as simple as a ball and as intricate as a human bone. 10 Cool 3D Printing Startups. Desktop Miracle: Machine Recycles Plastic Into 3D Printing Fuel. Three-dimensional printing is an amazing technology that may eventually take over the entire manufacturing industry.

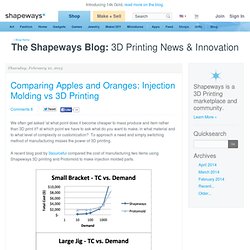

Vermont Technical College student Tyler McNaney is single-handedly revolutionizing the way this emerging technology is used by introducing the Filabot, a machine that turns plastic garbage into filament used to create amazing objects with 3D printers. McNaney’s Filabot includes parts to grind, melt down and extrude plastic into usable filament. Comparing Apples and Oranges: Injection Molding vs 3D Printing. We often get asked 'at what point does it become cheaper to mass produce and item rather than 3D print it?

At which point we have to ask what do you want to make, in what material and to what level of complexity or customization? To approach a need and simply switching method of manufacturing misses the power of 3D printing. A recent blog post by 3sourceful compared the cost of manufacturing two items using Shapeways 3D printing and Protomold to make injection molded parts. "In this case, we prices out two different parts. One, a very small bracket (~1cm^3) and one a larger jig (~50 cm^3). This is great for a simple equation for comparing the cost of a simple part required in bulk like their bracket, but if there is any level of complexity in the part or strict tolerances, the price to injection mold is likely to quickly increase, where as the price to 3D print would likely stay the same or may actually be reduced if the complexity is in the form of meshed or perforated features.