Muve3d. Muve3d. Felt Tips’s Videos on Vimeo. Large Format 3D Printers. Michael Ruddy reveals secrets behind his 3D printed 'Captain Hook' hook. Apr 7, 2016 | By Alec 3D printing is increasingly becoming the go-to technology for all things cosplay.

The web is filled with amazing Iron Man suits, while countless costumes at any con are completed with a few 3D printed props – regardless of who you’re cosplaying. But as any hobbyist will tell you, achieving the right final results after printing can be quite challenging. If you’re looking for some tips, here’s some good news: veteran prop artist Michael Ruddy of Hero Complex Props has just revealed some of the key techniques he uses to achieve high quality results on his 3D printed 'Captain Hook' hook. Michael Ruddy, of course, has previously shared a wide range of amazing 3D printed props through Hero Complex Props.

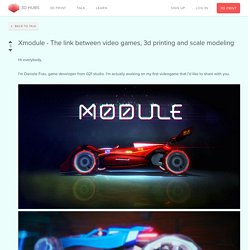

As he explains to 3ders.org, he is always asked exactly how he finishes those amazing projects. 3D printing itself is quite straightforward. The real magic begins once the 3D printing is completed and involves various key steps. Xmodule - The link between video games, 3d printing and scale modeling. Hi everybody, I'm Daniele Frau, game developer from G21 studio.

I'm actually working on my first videogame that I'd like to share with you. XModule is a sci-fi racing game that allows you to create your own concept car and 3D print each car component. Futuristic environments and powerful prototypes are the heart of this game that beats with a Drum&Bass rhythm. First, you'll choose which module you want to use for your career. You have to choose pretty carefully your module because you won't be able to change it afterwards. XModule is a sci-fi racing game that allows you to create your own concept car and 3D print each car component.

During the game you have to improve your module changing parts and settings. Our Best Tips about Wall Thickness for 3D Printing. When it comes to 3D printing disappointments, the fragility of the 3D print ranks high and fragile 3D prints amounts for lots of failures.

Though there are four essential things to check that could prevent a bad outcome when sending your 3D model to a 3D printer or a 3D printing service. The minimum scale of your model The modeling of your 3D file doesn’t necessarily require that you work with a given unit or scale. It’s particularly true with software like Blender in which you’re able to give proportion but no unit. This job will be done after the modeling phase when you send your model to a 3D printer. A powerful example of that can be found in architectural models. A 3D printed model for architectural purposes Once again the outcome can at best that the details won’t be printed and at worse they could break or even make the 3D printer crash.

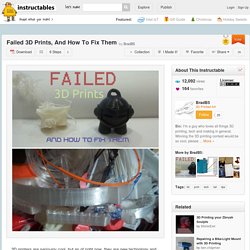

The minimum wall thickness of every material Every 3D printed materials (and therefore, technology) behaves differently. ROUGH-AND-TUMBLE:The first 3d self printable boardgame by Cross Lances. Home of Codename Colossus – Home of Codename Colossus. Shop3D.ca – Canada's Official Sales Partner for Ultimaker. Wireless 3D Printing · AstroPrint® Failed 3D Prints, And How To Fix Them. This is probably one of the most common ways any 3D print can fail. 3D printers work by building up objects layer by layer, and if the layers come off of the bed, you usually end up with plastic spaghetti instead of a clean printed part.

Three things contribute to bed adhesion: The bed surface (PET tape, glass, or other types) The material you are printing in (PLA, ABS, Nylon) And the heat of the bed (usually between 60 degrees and 90 degrees Celsius) The best adhesion I've found for ABS consists of a 80-90° bed, PET tape, with a thin film of Elmer's Glue stick on top. The best adhesion I've found for PLA is a 0-50° bed, PET tape or uncovered glass, and Elmer's Glue. Suggestions and methods from comments include: Member gravityisweak suggested his method: Use hair gel from the dollar store on hot glass for rock hard adherence with PLA. Member MikeTheSpike says: I print ABS at 220 degrees Celsius on a 110 degree bed.

3D-Printed Classical Paintings Will Let The Blind “See” Famous Art For The First Time. The Unseen Art project, which is being run by Helsinki-based designer Marc Dillon, is using 3D printing to give blind people the opportunity to experience classical art that many sighted people might take for granted.

“Imagine not knowing what Mona Lisa’s smile looks like, or Van Gogh’s sunflowers. Imagine you heard people talking about them and knew they existed, but could never experience them for yourself. For the millions of people who are blind, that’s a reality,” the project explains in a video. They use 3D imaging and sand-based 3D printing to recreate these works of art on a scale and quality that can be put on display in museums. Though their approach is unique, the Unseen Art project is not the first to have come up with this concept. 3D printing has been used to turn photos into “Touchable Memories” and even to help a blind mother “see” the ultrasound of her unborn child.

More info: unseenart.org | IndieGoGo | Facebook | Twitter. MAXTER·WIP. Nacho Riesco Art 3D Prints. ROBOPLASTIK. Index. Michael Milano, 3D Artist. Dark Samurai. Been trying out some of the new tools in 3D Coat 4.1 Also tested out the new physical based shader in Substance Designer 4.2 – looking forward to trying these out in the upcoming Unity 5 UPDATE Finally finished 3D printing and assembling all the parts (Lots of modelling putty and sanding!)

Ended up going with black paint and silver dry brushing – which helped to bring out the details but also showed up the build lines ;P. MAXTER·WIP. The Art of Thijs de Bruijn - The Art of Thijs de Bruijn. HQM_Introduction.