Ben Heck’s CNC Router Tutorial. Ceramic 3D printing with powder support. Sand casting: Digital production of complex sand moulds by voxeljet. Constructing Buildings Using 3D Printer. How To Eat Your Own (Chocolate) Brain! How to Make a Latex Mold: 9 Steps. == El Globo Bambalinas == Sculpture Supply Canada - Product Detail. Latex Rubber FMF 5 Gal(20L) (223625) Mold-Craft latex rubber is tapped from rubber trees in Burma, much like maple syrup is tapped from trees.

Mold-Craft is available in two forms: FMF_Flexible Mold Facing and FMB_Flexible Mold Backing consistencies. Packaged in 5 gallon (20 Litre) pail. PRODUCT ADVISORY: KEEP FROM FREEZING. May require heated service subject to weather conditions. Additional shipping charges will apply. Ideally, FMF and FMB compounds are used in combination. The thicker coats provide additional strength extending mold production life. FMF_Flexible Mold Facing: 60 - 65% total solids0.7% ammonia and others added to provide extended shelf lifeCompounded and pre-vulcanizedConsistency of milkFMF Mold-Craft applications include: small rubber molds, masks, rubber gloves, dipping and brush-on, crafting, special FX, animation, etc.

Do not make too thick as Mold-Craft can lose some of its stretching qualities. Always prevent from freezing. Latex_guide. Makeblock : Next Generation of Construct Platform by Makeblock » Using Makeblock to DIY a 3D (Chocolate) Printer ! Many kickstarters have asked if we are trying to build a 3D printer using Makeblock parts, and many want to build their own 3D printer using our kit.

Recently we've been working hard to make this vision a reality. Using Makeblock to build a 3D printer has always been part of our goal, and we will start to materialize it when enough people show their interests, please feel free to tell us what you think about this. In fact, there are several 3D printer projects readily found on Kickstarter. By contrast, our Makeblock 3D printer kits will be highly modular, most of the parts can be used to construct your other projects. And you can build different configurations with same parts, or extend it in the future with several new parts, for example, use longer beams to construct bigger machines. We take an OPEN-SOURCE approach in designing our Makeblock 3D printer parts. The print head and extrusion mechanism on the market are quite mature.

Choc Creator Vers 1 3D Printer. The World's first commercial 3D chocolate printer!

Design it, Print it, Eat it! Choc Creator is a simple, yet versatile desktop 3D chocolate printer. It has been developed for creative users who love to experience new technologies and exploit the broad technical settings and boundaries of the printer, whilst having a lot of fun with their creations. Choc Creator utilizes an easy-to-use syringe based chocolate deposition head which allows users to rapidly install and remove syringe head units. The design enables users to refill the syringe with fresh chocolate or different types of chocolates conveniently. Initial designs in chocolate, what will yours be? Chocolate Printing. Edible Chocolate Brain from MRI Scan. Overview This instructable will show you how to create an edible chocolate brain from sliced data sourced from an MRI scan.

Our colleague at Inition, Andy Millns had his brain MRI scanned as part of a research project (he didn't say what into!) And we managed to sneak a copy (get your copy below!). The main steps involved are: - Converting sliced DICOM data into the STL file format (a 3D geometry format widely used for 3D printing) - Editing that model to clean up - 3D printing a solid model - Producing a latex mould - Finally casting the chocolate and eating (image of Andy eating his own brain above).

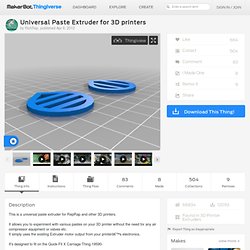

We've made the original DICOM files and the STL file available for download below under the Creative Commons Attribution License. If you like the project - we would be very happy if you voted for it in the Instructables 'Make it Real' challenge - the voting button is top right of this page. Build Your Own CNC Router, CNC Machine, or 3D Printer. Universal Paste Extruder for 3D printers by RichRap. An assembly video for the Universal Paste Extruder can be found here, giving you details of how to build one up - youtu.be/iiyEOKpz_b8 You can print with Ceramic Clays, Silicone, Sugar pastes, solder paste for PCB assembly, Chocolate, Frostings, Masa Harina, and all sorts of other food’s or pastes that can be extruded through a syringe.

A Blog post on the Extruder is Here - richrap.blogspot.co.uk/2012/04/universal-paste-extruder-ceramic-food.html Printing with Sugar paste video - youtu.be/vEqLvqTCDko Printing with Chocolate - youtu.be/tbVVT0Q0PyU Printing with Porcelain Clay - youtu.be/x8ILdNDrXrc. Universal Paste extruder - Ceramic, Food and Real Chocolate 3D Printing... Happy Easter Everyone, I'm a little late with this post, it's been a very busy month. This particular 3D printing adventure started last August (2011) after seeing a few news reports on 3D Chocolate printing, it had always been on my list of things to try, after reading the reports and looking at the rather over marketed video of a machine doing essentially nothing...

I was really frustrated that the technology didn't seem that accessible or even that revolutionary considering they described it as the "worlds first Chocolate printer" It looked like the University of Exeter had decided not to show any videos of the printer actually doing anything to do with the printing process. - See the PR page and video Here. It does make a reasonable point about the end user specifying the custom design for themselves, much as we already see with 3D printing. Fab Labs - On 3D Printing. Featured Fab Lab: FabCafe, 3D Printing and Coffee in Tokyo Featured Fab Lab: FabCafe Tokyo FabCafe is a space that conveys the FAB spirit in a fun, delicious and easy to understand way.

In the center of Shibuya, an area overflowing with youthful energy, FabCafe provides a space where people can enjoy making things in an exciting environment furnished with a variety of digital fabrication tools, including a laser cutter and 3D printers. Printing Ceramic on YouTube. Cookies Disabled. Rapid Prototyping Journal Volume 17, Issue 3, 2011, Pages 187-194 Marchelli, G. , Prabhakar, R., Storti, D., Ganter, M.

Retrieving additional authors... Cementenous Metalcasting Formula. Our presentation ( Laura West and Mark Ganter) at Ars Mathematica in Paris was a great success and as promised we are jointly releasing our cemetenous metal casting formula for you to play with.

What follows is a series of tips along with the formula. Of course we found that it also works quite nicely for sculptural forms and has the unique quality of not needing an infiltration. The formula simply is: 1000 parts VersaBond 250 parts Maltodextrin 250 parts PVA powder These molds should be approached much like sand molds. You will find that you need to print adjust your powder setting to be fairly wet, but not so wet that the part pulls away from its surroundings.

For a finer surface on your cast you may want to paint or spray a thin layer of mold wash on the surface. A good resource for sand casting techniques is “The Complete Book of Sand Casting” by C. Students win prize with device that turns plastics into toilets. 26 October 2012 A new 3D printer design could help turn discarded plastics into composting toilets and components for rainwater collection systems.

The device, built by students from Washington University in Seattle, was the winning entry for an international contest to use 3D printing to produce technologies for the developing world. The 3D4D Challenge competition, sponsored by UK charity techfortrade.org, presented its $100,000 (£62,000) prize to three undergraduate members of a 3D printing club; the prize will fund the formation of a non-profit company to develop the technology in Oaxaca, Mexico. Matthew Rogge, who presented the project at the competition final, came up with the idea while building irrigation and sanitation systems with the US Peace Corps in Ghana, Panama and Bolivia. Frustrated by the problems of building custom parts with limited resources, he read up on 3D printing and decided to embark on a postgraduate engineering course on his return to the US.