Polyester Glassfibre Tube - 25.4mm x 19.4mm - East Coast Fibreglass Supplies. Glass Fibre Reinforced Rods. Canoe Sail: 5 Steps. AdWords We use AdWords to deploy digital advertising on sites supported by AdWords.

Ads are based on both AdWords data and behavioral data that we collect while you’re on our sites. The data we collect may include pages you’ve visited, trials you’ve initiated, videos you’ve played, purchases you’ve made, and your IP address or device ID. This information may be combined with data that AdWords has collected from you. We use the data that we provide to AdWords to better customize your digital advertising experience and present you with more relevant ads. LiveRamp We use LiveRamp to deploy digital advertising on sites supported by LiveRamp. Doubleclick We use Doubleclick to deploy digital advertising on sites supported by Doubleclick. RocketFuel We use RocketFuel to deploy digital advertising on sites supported by RocketFuel.

Twitter We use Twitter to deploy digital advertising on sites supported by Twitter. Facebook. Screw propeller - STL,SOLIDWORKS. Robbins Timber - Marine Plywoods. Epoxy - Fyne Boat Kits. Professional Epoxy Coatings A versatile solvent-free slow-cure epoxy that can be used for joints, fillets, glass fabric saturation and coating. £27.501.5 kg£483 kg£87.506 kg£117.508 kg£193.5014 kg More information Epoxy Bundles Bundles of epoxy and consumables for building or repairing canoes, kayaks and boats.

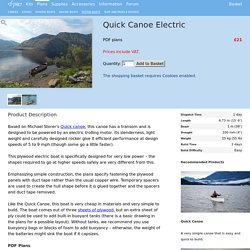

Quick Canoe Electric – a simple, cheap electric powered boat. Square back Electric Canoe. A new photo of an Electric Quick Canoe by Joe Koenicke – click his name for more Quick Canoe Adventures.

Detailed Plan $30 Click on your nearest agent in menu on left or see them listed here – this is a new plan so might not be up on all their websites yet, email them if you don’t see the plan. For a paddling canoe see the Quick Canoe here It is amazing how things fit together sometimes. Mixing one of my Quick Canoes with an electric trolling motor. Easy to build and cheap materials costLight Weight in plywood (65lbs – 28kg)Cheap trolling motors are availableMany people already have trolling motorsClever builder who adapted the planLow running cost.

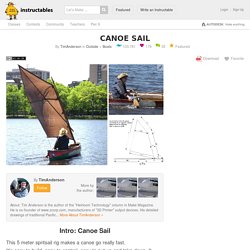

Quick Canoe Electric - Fyne Boat Kits. Product Description Based on Michael Storer's Quick canoe, this canoe has a transom and is designed to be powered by an electric trolling motor.

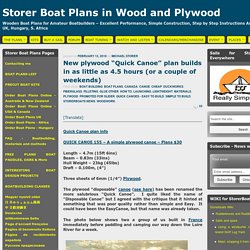

Its slenderness, light weight and carefully designed rocker give it efficient performance at design speeds of 5 to 9 mph (though some go a little faster). This plywood electric boat is specifically designed for very low power – the shapes required to go at higher speeds safely are very different from this. Emphasizing simple construction, the plans specify fastening the plywood panels with duct tape rather than the usual copper wire. Temporary spacers are used to create the hull shape before it is glued together and the spacers and duct tape removed. Untitled. New plywood “Quick Canoe” plan builds in as little as 4.5 hours (or a couple of weekends) Quick Canoe plan info QUICK CANOE 155 – A simple plywood canoe – Plans $30 Length – 4.7m (15ft 6ins) Beam – 0.83m (33ins) Hull Weight – 23kg (45lbs) Draft – 0.100m, (4″) Three sheets of 6mm (1/4″) Plywood.

The plywood “disposable” canoe (see here) has been renamed the more salubrious “Quick Canoe”. I quite liked the name of “Disposable Canoe” but I agreed with the critique that it hinted at something that was poor quality rather than simple and Easy. The photo below shows two a group of us built in France immediately before paddling and camping our way down the Loire River for a week. It fills a gap that our classic Eureka plywood Canoe doesn’t cover. The Quick Canoe series has been designed to be as easy to build as possible while keeping some of the qualities of a good paddling canoe – in particular the ability to track. One Sheet John boat... Why can't a one sheet dinghy carry two adults?

Surface treatment of a wooden boat. The purpose of surface treatment of a wooden boat is, at least, to: 1.

Prevent water from getting into the wood Why should water not get into wood? First of all, as explained earlier, wood swells and shrinks along with its moisture content. A wooden boat is full of structural details, where pieces of wood have been joined with crossing grain directions (as an example, every plank is fastened to every frame at both edges). There is no way to prevent movement of moisture to and from wood totally.

Water comes in two brands. Water vapor gets absorbed in wood cell pipe walls, but does not under any circumstances cause the cell hollow to fill. Liquid water gets absorbed in wood cell pipe walls, and can also fill the cell hollow. Cell walls can absorb water up to 25-30 % of wood dry weight. This can only happen, if the air relative humidity stays at 100 % for a long period of time.