PETG Temperature tower by pixelpeeper. Using the Arduino PID Library for precise position control of X and Y axis on RepScrap printer. * Lin_Enc_02.ino 05-12-2014 unix_guru at hotmail.com @unix_guru on twitter * * This sketch allows you to run two salvaged printer carriages for X/Y axis using their * linear encoder strips for tracking. * This example uses the Arduino PID Library found at: * * Hardware Interrupt 0 on Digital pin2 is used to determine X-Axis position * Hardware Interrupt 1 on Digital pin3 is used to determine Y-Axis position * PinchangeInterrupt is used to identify the Zero Endstop for X and Y axis.

Grbl Controller 3.0. Downloads: Souce Code: Record Issues Found: Grbl Controller is software that is designed to send GCode to CNC machines, such as 3D milling machines.

It isn’t super smart, it just needs to give the user a nice way to get commands down to whatever controller they are using. Version 3.0 is has been optimized for the Arduino to control Grbl shields. Grbl Controller is written using the Qt cross-platform libraries. Qt is pretty cool because you can create a nice GUI application for Windows, Mac and Linux. Why am I writing about this? I found a project on github called GrblHoming aka Grbl Controller, which was originally developed by Kosme, which showed promise for running native C++ on Linux, however it needed some attention. I forked the project and started tweaking it to compile and run under Linux. Magnetic Rotary Encoder v1.0. If your RepRap only uses stepper motors, like most of the top-rated RepRaps in the Comparison of Electronics, and you run them at low speed and low acceleration so they don't skip steps, you don't need this or any other encoder.

However, if you want to run faster than possible with a stepper motor, read on. As of 2014, this is the most recent magnetic rotary encoder designed for RepRap. As of 2014, this is the best encoder of any kind designed for RepRap -- see RepRapServo 1 0 for an overview of various kinds of encoders. I am a part of both, Generation 2 Electronics and Generation 3 Electronics Systems. This is an advanced, surface mount board. Don't worry though, You Can Do It! The Magnetic Rotary Encoder board is based around the Austria Microsystems AS5040 chip.

Get It! There are currently no known kit sellers. Files You can download the electronics files from Sourceforge. This file contains the following: Schematic Interface Pinout Build It Circuit Board Components Soldering Instructions. Closed Loop Control For 3D Printers. One of the bigger problems with any CNC machine or 3D printer is the issue of missed steps when moving the toolhead.

If a stepper motor misses a step, the entire layer of the print – and every layer thereafter – will be off by just a tiny bit. Miss a few more steps, and that print will eventually make its way into the garbage. [Misan] has the solution to this: closed loop control of DC motors for a 3D printer. Most printer firmwares use an open loop control system for moving their motors around. Step a few times in one direction, and you know where the nozzle of a 3D printer will be.

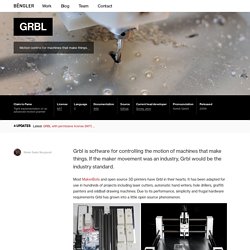

[Misan]’s solution to this was a DC motor coupled to an optical encoder. The entire build is heavily derived from ServoStrap, but [Misan] has a very cool demo of his hardware: during a print, he can force the X and Y axes to either side, and the Arduino in each motor will move the print head back to where it needs to be. GRBL. Grbl is software for controlling the motion of machines that make things.

If the maker movement was an industry, Grbl would be the industry standard. Make: DIY Projects, How-Tos, Electronics, Crafts and Ideas for Makers. G-code. This page tries to describe the flavour of G-codes that the RepRap firmwares use and how they work. The main target is additive fabrication using FFF/FDM processes. Codes for print head movements follow the NIST RS274NGC G-code standard, so RepRap firmwares are quite usable for CNC milling and similar applications, too. There are a few different ways to prepare GCode for a printer. One is to use a slicer like Skeinforge or Cura. These programs take a CAD model, slice it into layers, and output the GCode required for each layer. As many different firmwares exist and their developers tend to implement new features without discussing strategies or looking what others did before them, a lot of different sub-flavours for the 3D-Printer specific codes developed over the years.

Introduction A typical piece of GCode as sent to a RepRap machine might look like this: The meaning of all those symbols and numbers (and more) is explained below. Arduino GCode Interpreter. This page describes something which is no longer the most recent version.

For the replacement version see: G-code This page has been flagged as containing duplicate material that Darwin/Arduino GCode Interpreter also attempts to cover.These pages should be merged such that both pages do not attempt to cover the duplicate topics. Arduino-gcode-interpreter - 3D printer list. Parametric Open SCAD Timingbelts by doommeister.

Www.cwrailways.com - 3D Print, 3D CAD, Model Railways, 7mm scale, 0-16.5, 009, 0-14, 5.5mm scale, 00 scale, 4mm scale, Lynton & Barnstaple, Seaton Tramway, Peco, 3D Hubs: Local 3D printing services and 3D Printers.