Hack your servo v3.00 - Get full PID position and speed control from your hobby servo. Yes we like servo mods!

As promished this is the third servo hack. This builts upon the second hack - 'add 10-bit abolute/incremental feedback encoder to your hobby servo' - node/18470. Source code is open and links provided at the end of the post. Schematics are also provided. In terms of the board files... well dont be lazy! IIC LCD Backpack. The Arduino OBD-II Adapter works as a vehicle OBD-II data bridge for Arduino with open-source Arduino library provided.

Besides providing OBD-II data access, it also provides power supply (converted and regulated from OBD-II port) for Arduino and its attached devices. [b]Features[/b][list][li]Directly pluggable into vehicle’s OBD-II port[/li][li]Serial data interface (UART for [url= or I2C for [url= efficiency DC-DC module for 5V/3.3V DC output up to 2A[/li][li]Supporting CAN bus (used by most modern cars), KWP2000 and ISO9141-2 protocols[/li][li]Accessing all OBD-II PIDs provided by the vehcile ECU[/li][li]Embedded 3-axis accelerometer, 3-axis gyroscope and temperature sensors ([url= only)[/li][li]Extendable and actively maintained Arduino library and example sketches provided[/li][/list] [b]Enhanced features of TEL0068[/b] TEL0068 has an additional MPU6050 module built inside, which provides accelerometer, gyroscope and temperature sensor all accessible via I2C.

Labs / DC Motor Control Using an H-Bridge. Overview In this tutorial, you'll learn how to control a DC motor's direction using an H-bridge.

To reverse a DC motor, you need to be able to reverse the direction of the current in the motor. The easiest way to do this is using an H-bridge circuit. There are many different models and brands of H-Bridge. This tutorial uses one of the most basic, a Texas Instruments L293NE or a Texas Instruments SN754410. If you simply want to turn a motor on and off, and don't need to reverse it, for example if you're controlling a fan, try the tutorial on controlling high current loads with transistors.

(:toc Table of Contents:) Robotic Arm – Hardware. This is first in series of articles about project I've been building in my spare time since last Summer.

Actually it all began when I was researching a topic of modeling human motion kinematics in order to create gesture recognition library for Kinect. This ties heavily into motion theory of robotic manipulators so I also glanced at some designs of robotic arms. Somehow I stumbled upon this cool looking open source robotic arm: It was featured on Thingiverse and published by user jjshortcut (Jan-Jaap).

Since for some time I got hooked on toying with microcontrollers, robots and other electronics, I decided to give it a try and build it myself. Another reason to build the arm myself was the cost factor. Laser cut parts Some time ago I’ve build another robot using laser cut parts so I knew the process already. All parts are cut from 4 mm thick material. Metal parts I bought all the M3 screws and nuts at local hardware store.

Download. Uptech CDS 55XX Serial Robot Servo (Robotis AX Compatible) The Uptech CDS 55XX Serial Robot Servo (Robotis Compatible) has been launched with the aim to solve most important problems caused by R/C servos in robot and simultaneously inheriting most of the advantages of them.

Because of the advanced position sensor and precise A/D converter gives the high position accuracy, the position resolution in position-mode can be up to 0.3°. The response time is up to 2ms contrast a 20ms of traditional R/C servo. The CDS series robot servo can be linked by serial bus, which can connect up to 200+ servos. Each unit can feedback its position, rotation velocity, torque, current, motor temperature and so on. The robot built with robot servos can set actions through artificial demonstration, that is, the user can regulate the robot’s joints posture with hands and the robot can record the parameters like location, speed, etc. It can do rotating all round, and the velocity can be controlled, just act as a gear motor. Motor Driver - L293D - 1. Motor Driver and H-bridge basics Generally, even the simplest robot requires a motor to rotate a wheel or performs particular action.

Since motors require more current then the microcontroller pin can typically generate, you need some type of a switch (Transistors, MOSFET, Relay etc.,) which can accept a small current, amplify it and generate a larger current, which further drives a motor. This entire process is done by what is known as a motor driver. Project Biped. High power electric motor kit. Www.robives.com. Let's Make Robots! Servos and parts>All Servos.

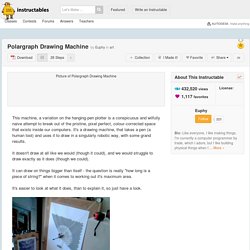

Polargraph Drawing Machine. Confirm you have set the right serial port, and that it's communicating with the arduino by looking for a Polargraph READY!

At the top of the window. This line will be red if it's not connected. If you connect the machine after starting the controller, then you'll probably need to close and restart the controller too. If you're running from Processing, then you should also be seeing incoming: READY in the Processing console every couple of seconds, in the background. That's great! Ok, now click the Move pen to point button, which is as close to a manual move command as you have, and click somewhere right down at the bottom of the machine. The purple spot will move too. Try this again, and make sure the sprockets are moving in the right direction. If one, or both of your motors are going in the wrong direction, you might have got your datasheet wrong, or made an error when labelling them up or something. Good work!

Elektronikkomponenter. Robot controllers. S3 Tilt and Pan System. Starter Pack Which Includes Everything for Controlling a Servo from a PC. If you have never used a servo before, let alone control one from a PC, then the “Servo Pack” provides an easy “plug-and-go” solution.

Once you have the Servo running under PC control the knowledge and confidence you gain by actually using a Servo is invaluable in applying those techniques to a wide range of applications. The Servo supplied is one of the most popular types on the market and understanding its principles of operation provides a solid basis for using many other types. - For those who are already familiar with servos, the servo pack offers a very convenient way of adding a servo to your PC application. - For programmers, the supplied DLL means you have a servo that is instantly controllable from within your own program (Visual Basic, C, C++ etc…) Robot fish synchronise into schools. Swarm-bots project. USD Modular Robotics Research Lab - modular. Projects. DPRG Events Shoptalk Support the DPRG We need your help to keep going!

Click the button to find out how you can help support our work! Website design and hosting by NCC DPRG members are constantly working on robot projects. The dates on these projects represent the date the project was initially documented. If you'd like to join one of the group projects seen here or just offer a comment on one of the indvidual projects, why not join us on the DPRG mailing list?