Assemblages Nippons ! Precise table saw cuts to make a puzzle. Jenga pistol 2. The game of Jenga was possibly designed to be a more contemplative and strategic game.

But sliding those blocks out carefully without knocking over the stack is just entirely too fiddly a task to perform. I figured it would be much more fun to just be able to shoot the blocks out with some sort of pistol. The animation at left was extracted from a video shot at 60 frames per second. It takes three frames, or about one twentieth of a second, from the point that the trigger is released to the Jenga block clearing the stack. As a precaution, I'm pulling the pistol back immediately after the shot, to avoid having the stack fall on the pistol's bolt. The pistol works by hurling a wooden captive bolt forward inside the pistol, powered by rubber bands.

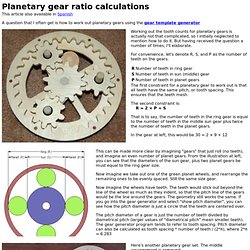

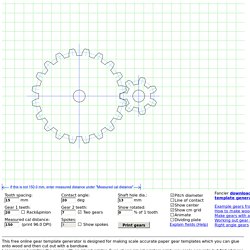

How to make wooden gears. This page also available in Spanish Some people are intimidated at the prospect of making their own wooden gears for the screw advance box joint jig. Planetary gear ratio calculations. This article also available in Spanish A question that I often get is how to work out planetary gears using the gear template generator Working out the tooth counts for planetary gears is actually not that complicated, so I initially neglected to mention how to do it.

But having received the question a number of times, I'll elaborate. For convenience, let's denote R, S, and P as the number of teeth on the gears. Historical Thursday: Da Vinci’s Clockwork Car. Queue_aronde. Making dovetail joints with the pantorouter. The dovetail joint is not my favourite type of wood joint.

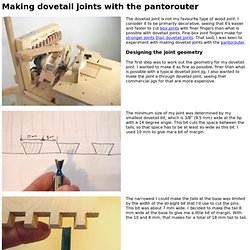

I consider it to be primarily decorative, seeing that it's easier and faster to cut box joints with finer fingers than what is possible with dovetail joints. Fine box joint fingers make for stronger joints than dovetail joints. That said, I was keen to experiment with making dovetail joints with the pantorouter. Designing the joint geometry The first step was to work out the geometry for my dovetail joint.

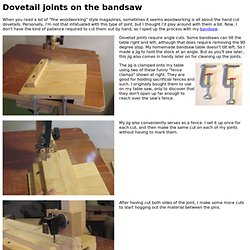

The minimum size of my joint was determined by my smallest dovetail bit, which is 3/8" (9.5 mm) wide at the tip with a 14 degree angle. The narrowest I could make the tails at the base was limited by the width of the straight bit that I'd use to cut the pins. Dovetail joints on the bandsaw. When you read a lot of "fine woodworking" style magazines, sometimes it seems woodworking is all about the hand cut dovetails.

Personally, I'm not that infatuated with this type of joint, but I thought I'd play around with them a bit. Now, I don't have the kind of patience required to cut them out by hand, so I sped up the process with my bandsaw. Dovetail joints require angle cuts. Some bandsaws can tilt the table right and left, although that does require removing the 90 degree stop.

My homemade bandsaw table doesn't tilt left. The jig is clamped onto my table using two of these funny "fence clamps" shown at right. Defonceuse et fraises. Gear template generator. This free online gear template generator is designed for making scale accurate paper gear templates which you can glue onto wood and then cut out with a bandsaw.

I recommend printing the gears with an ink jet printer. Even cheap ink jet printers print very scale accurate but Not all laser printers are accurate. You can still access the old (pre 2015) Flash based gear geberator Getting the printout to scale correctly, avoiding cropping Different browsers print at different scales depending on browser type and printer configuration. How to Plane a Board with a Router.mov.

HMDIFFUSION. Ponçage avec une ponceuse à bande. Depuis quelques décennies, le monde de l'ébéniste à beaucoup évolué.

Machines et outils de diverses marques envahissent le marché et ce n'est pas pour nous déplaire. Mais tout investissement mérite réflexion. Que peut m'apporter tel ou tel matériel. Vient-il compléter, doubler,ou remplacer celui existant ? Voilà de bonnes questions ! C'est la plus utile de toutes les machines de ponçage, mais aussi la plus difficile à maîtriser. Méthode d'utilisation Zoom La mise en marche de la machine se fait lorsque la semelle est en parfait contact avec la surface à poncer, le déplacement doit être simultané. La pièce à poncer doit être solidement fixée sur l'établi. On finit avec ce grain par un passage dans le sens du fil jusqu'à disparition des rayures de travers. Zoom Un cadre de porte de meuble, comportant des traverses et montants (donc des surfaces en fil croisé) peut également se poncer à la bande. Free Wood Router Jig Plans - How to Build A Wood Router Jig.

This router jig is so easy to make and so easy and accurate to use, you will be kicking yourself for not thinking of doing this sooner!

This is the jig you need to set up fast, straight, accurate router slots with your router. If you perform a lot of router cuts to receive panels, this is the portable jig you want to have on site. Materials: One, 2 x 4 x 16"; Cross piece. One, 1 x 3 x 36" used for the material guide rail. 4, 1 5/8" Wood Screws. Step 1 - Select 2 x 4 x 16" and a scrap 2 x 4 for a support brace. Step 2 - Select your router with a gouging bit about 1/4" deep, and place it along the Guide Rail and make a pass on each side of the rail as shown above; you are done!

Try it Out! For Great Router Information, Click Here! More FREE Plans!