Industrial robots and robotic automation systems - Motoman Robotics. Apple - Making the all-new Mac Pro. This Robot Is Changing How We Cure Diseases. Geerts Deep Drawing - geerts, specialist in deep drawing. Home - Richards Wilcox Conveyor Systems. Conveyor systems - SSI SCHÄFER. Industrial Conveyor System. TS Assembly Conveyors - TS Assembly Conveyors - assembly, automated machinery, automation, automotive, belt conveyor, conveyor chain, conveyor system, medical, pallet conveyor, roller conveyor.

Conveyor Technology - mk Technology Group. We offer the suitable conveyor system for virtually all transport goods and implementation conditions.

Conveyor Systems: Belt Conveyors, Chain Conveyor And More Co. Redler provide a full range of conveyor systems which are designed to increase efficiency in material handling.

Using En-Masse MoveMaster technology, Redler provide comprehensive material handling systems. Redler conveyor systems are varied and suitable for a wide range of purposes. Cornerstone Automation Systems. Conveyor Systems Manufacturer CASI manufactures a wide variety of conveyors, conveyor controls, and accessories.

Our pre-engineered approach guarantees the right conveyor system for your application. There are many considerations such as speed, product type, and integration needs. CASI engineers will help you determine the scope and help to establish a realistic budget in designing the right conveyor system. Home. Bendy snake-arm robot piques interest of multiple industries. Engineers at a robotics design firm in Bristol, UK have come up with a unique snake-like machine that wouldn’t look out of place in a big budget sci-fi movie.

Developed by OC Robotics, engineers have been working on the revolutionary bendy robot, known as the snake-arm, for the last 10 years. The result is a remarkable piece of technology that can, according to its designers, “reach the unreachable.” Industries around the world have been showing an interest in the snake-arm, including the nuclear sector, where the robot could be sent into confined spaces or into places too dangerous for humans. OC Robotics’ managing director, Rob Buckingham, spoke to CNN about the development of the snake-arm. “Just like the human arm, the big muscles that drive them are actually mounted on the back and tendons link the muscles to the joints.” Operation is straightforward enough, with a person using only a computer screen and a control pad. Below is a BBC report showing the impressive snake-arm in action. Modular Snake Robots - CMU Biorobotics.

Robotic Snake Can Slither Up Your Leg. Modular Snake Robots. Carnegie Mellon Modular Snake Robots for Cave Rescue ... and Mars? Hands-on First Look (With Video!) CHICAGO — Menacing, mechanical snakes slithered their way all around the robotics exhibits this weekend here at Wired NextFest.

Some did barrel rolls around cinder blocks, while others wormed their way up their owners' pant legs, squeezing and relaxing like living, breathing reptiles. Maxon DC motors drive robotic snake-arms into tight spaces. A robot that is as agile as a snake can explore almost any hidden nook and cranny.

Problems can often occur moving in confined and hazardous spaces, and whilst these spaces are difficult for humans to work within, a snake-arm robot has no issue. Whether for aircraft assembly, nuclear power stations or the inspection of pipes and sewage systems: maxon DC motors are responsible for the high-precision movements of the multiple degree-of-freedom robotic snake-arm. Just like in a science fiction film, the robotic snake-arm wriggles through a small hole. Its task is to conduct a safety inspection in a hard to reach location, recording video as it goes.

Confined and hazardous spaces are common in many industrial applications. Each arm is customised specifically for the particular application that it will be used for. Always following its nose. Brushless maxon DC motors for flexible movements.In a human arm, the tendons connect the muscles to the bones of the joints. FANUC Robotics - Industrial Robot Automation.

Machinery Automation & Robotics - The Automation & Robotic Experts. Robotics - SCARA and 6 axis industrial robots & software solutions - Stäubli. Content Known worldwide for the quality of our design and innovation for more than a century, the Stäubli Group has brought its renowned engineering expertise and technological ingenuity to the forefront of robotics.

Since 1982, we have built a highly regarded robotics business, and more significantly, transformed the way thousands of manufacturing operations perform. Today Stäubli Robotics is a leading player in robotics around the world, consistently delivering engineering as effective and reliable as our service and support. Manufacturer of Pick and Place Machines. At ICS Robotics, we have teamed up with ABB Robotics to offer pick and place machine options integrating their class-leading range of 6-axis and Delta style robots.

ABB Robotics are a leading brand in robotic automation and have been developing high performance, function-packed robot systems for over 25 years. The ABB range encompasses robots for all applications with payloads from 1 to 500kg. Robotics. Industrial robots and robotic automation systems - Motoman Robotics. Robotics. Panasonic Robot and Welding Systems – Industrial robots.

Welding Equipment and Consumables for Automotive Transportation Industries. Automotive Industry from Rockwell Automation. New manufacturing approaches are needed across your supply chain.

You need to globally connect your enterprise, integrate flexible manufacturing processes to accommodate multiple models at the same facility, and gain better insight into your manufacturing operations. Rockwell Automation can help you develop manufacturing velocity strategies so you can implement business process improvements, increase access to real-time production information and improve supply chain integration across your enterprise. Connected Enterprise Rockwell Automation automotive MES solutions can help your business more easily share production data across plants and global business systems for better decision making and competitive advantage.

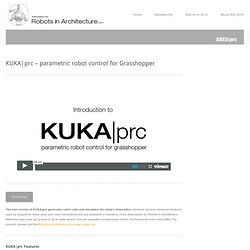

Risk Management Coordination of multiple vendors and thousands of data points drives risk management. Integrated Information. Products & Services. KUKA Industrial Robots. Prc » Association for Robots in Architecture - Download The trial version of KUKA|prc generates robot code and simulates the robot’s kinematics.

However, several advanced features such as support for linear axes and more robots/tools are only available to members of the Association for Robots in Architecture. Members also have got access to up-to-date version that are uploaded at least every month, but frequently even more often. For support, please visit the Robots in Architecture forum or contact us! KUKA|prc enables you to program industrial robots directly out of the parametric modelling environment, including a full kinematic simulation of the robot. KUKA|prc is a range of custom components packaged as a plugin for the parametric design software Grasshopper, which in turn is a plugin for the NURBS modeller Rhinoceros.

The current KUKA|prc version was tested with: Rhinoceros 5 Grasshopper 0.9.0056/61. Robots in Architecture. We recently presented our paper "A New Parametric Design Tool for Robot Milling" at the ACADIA 2010 conference in New York. We had a great time there and thank all of our friends who got up on a Sunday morning - after the big party, no less - to follow our presentation. In our paper we show approaches on how to integrate the robot not just in the parametric model, but in the design process itself. The example above is a screenshot (with added captions) directly out of Grasshopper, showing the initially created curves, the resulting modules and finally the stacked wall - side by side with a preview of the toolpaths, including the possibility to simulate the end-effector movements and extract KRL (KUKA Robot Language) code.

It's all running very fluently, allowing you to quickly iterate alternatives, both in respect to design and production. You can download the full paper here.