Smart Glass, Smart Windows, Smart Glass Film. Metal foam. ALU composite panels. Powder coating. Aluminium extrusions being powder coated Powder coated bicycle frames and parts Properties of Powder Coating[edit] Because powder coating does not have a liquid carrier, it can produce thicker coatings than conventional liquid coatings without running or sagging, and powder coating produces minimal appearance differences between horizontally coated surfaces and vertically coated surfaces.

Because no carrier fluid evaporates away, the coating process emits few volatile organic compounds (VOC). Finally, several powder colors can be applied before curing them all together, allowing color blending and bleed special effects in a single layer. Most powder coatings have a particle size in the range of 30 to 50 μm, a softening temperature Tg around 80°C, a melting temperature around 150°C, and are cured at around 200°C.[1] For such powder coatings, film build-ups of greater than 50 μm may be required to obtain an acceptably smooth film.

Types of powder coatings[edit] Nickel. Nickel electroplating. Nickel electroplating is a technique of electroplating a thin layer of nickel onto a metal object.

The nickel layer can be decorative, provide corrosion resistance, wear resistance, or used to build-up worn or undersized parts for salvage purposes.[1] Overview[edit] Types and chemistry[edit] Coin. Anodizing. These carabiners have an anodized aluminium surface that has been dyed; they are made in many colors.

Anodizing is also used to prevent galling of threaded components and to make dielectric films for electrolytic capacitors. Anodic films are most commonly applied to protect aluminium alloys, although processes also exist for titanium, zinc, magnesium, niobium, zirconium, hafnium, and tantalum. Iron or carbon steel metal exfoliates when oxidized under neutral or alkaline microelectrolytic conditions; i.e., the iron oxide (actually ferric hydroxide or hydrated iron oxide, also known as rust) forms by anoxic anodic pits and large cathodic surface, these pits concentrate anions such as sulfate and chloride accelerating the underlying metal to corrosion. Carbon flakes or nodules in iron or steel with high carbon content (high carbon steel, cast iron) may cause an electrolytic potential and interfere with coating or plating.

Shape-memory alloy. A shape-memory alloy (SMA, smart metal, memory metal, memory alloy, muscle wire, smart alloy) is an alloy that "remembers" its original shape and that when deformed returns to its pre-deformed shape when heated.

This material is a lightweight, solid-state alternative to conventional actuators such as hydraulic, pneumatic, and motor-based systems. Information. GCSE Bitesize: Smart materials. 290. Thermochromism. A mood ring shown face front.

Note the band of color change. Thermochromism is the property of substances to change color due to a change in temperature. Amazon.co. Frequently Bought Together Customers Who Viewed This Item Also Viewed.

Thermochromic sheet. Rockets. Model Rocketry encompasses many aspects of advanced science.

As such, the new interest in the rocketry community for night launches has spurred some interesting innovations. But shooting rockets at night does not have to be "rocket science". You just need a rocket that can be tracked in the air and located after decent. Glow in the dark paint offers this need with low cost, low weight, and no requirement for batteries. Paint based lighting also clearly adds to the scientific level of a rocketry project. Painting a rocket with glow in the dark paint is relatively easy. Glow in the Dark Paint - Water Based. Glow in the Dark Rocks. Glow in the Dark Sand. Gun Sights. Official Statement The owners of Glow Inc. support the legal and responsible ownership of weapons by both law enforcement and citizens.

In the unfortunate scenario where there is a need to discharge a weapon, improved accuracy lowers the probability of injury to an innocent bystander. We feel that phosphorescent paint is a vital component of increasing this accuracy in dark environments. Your typical criminal will not take the effort or pay the cost to apply phosphorescent paint to his weapons. Therefore, we believe that making this information available is for the good of the community and hopefully will save a few innocent lives. Plym1. Poly2. Polymorph. Polymorph Casting - How to. Gorilla Glass. Gorilla Glass is the registered trademark for an alkali-aluminosilicate sheet toughened glass manufactured by U.S. glassmaker Corning Inc.

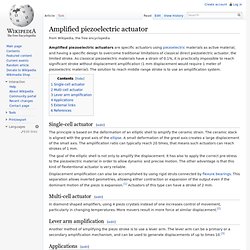

Engineered for a combination of thinness, lightness, and damage-resistance, it is used primarily as the cover glass for portable electronic devices including mobile phones, portable media players, laptop computer displays, and some television screens.[1] It is manufactured through immersion in a molten alkaline salt bath using ion exchange to produce compressive residual stress at the surface. Electronic Smart Glass. Smart Glass in houses. Smart Glass. Amplified piezoelectric actuator. Amplified piezoelectric actuators are specific actuators using piezoelectric materials as active material, and having a specific design to overcome traditional limitations of classical direct piezoelectric actuator, the limited stroke.

As classical piezoelectric materials have a strain of 0.1%, it is practically impossible to reach significant stroke without displacement amplification (1 mm displacement would require 1 meter of piezoelectric material). The solution to reach middle range stroke is to use an amplification system. Single-cell actuator[edit] The principle is based on the deformation of an elliptic shell to amplify the ceramic strain. The ceramic stack is aligned with the great axis of the ellipse. The goal of the elliptic shell is not only to amplify the displacement.

Piezo-Electric Actuator. Waterproofing. Waterproofing is making an object virtually impervious to water. NeverWet Arrives - Hands-On Product Demonstration. Paper-Backed Veneer Pricing and Pictures. Desktop-closeup-large. More info. Bending Ply. Flexiply3. Flexiply1. Information. Information 2. Mosquito. Difference. Plywood. Wing plywood. Medium-density fibreboard. Medium-density fibreboard (MDF) is an engineered wood product made by breaking down hardwood or softwood residuals into wood fibres, often in a defibrator, combining it with wax and a resin binder, and forming panels by applying high temperature and pressure.[1] MDF is generally denser than plywood. It is made up of separated fibres, but can be used as a building material similar in application to plywood. It is stronger and much more dense than particle board.[2] The name derives from the distinction in densities of fibreboard. Large-scale production of MDF began in the 1980s, in both North America and Europe.[3] Physical properties[edit] Over time, the word "MDF" has become a generic name for any dry process fiber board.

Types[edit] MDF. Bendy MDF. Flexible MDF. Flexible MDF.