Low Differential Stirling. All Stirling engines require that a temperature differential be maintained between the “hot” and “cold” parts of the engine. In the 1980s, Professors Ivo Kolin and James Senft developed a series of engines exploring the minimum temperature differential that could be made to work. 13 Dr. Senft’s basic design has been widely copied and is now available as a kit or completed engine from a number of model engine manufacturers.

The heat from a cup of coffee is usually enough to power it. If carefully constructed, it will even run from the warmth of your hand. The engine is of the split cylinder type or gamma configuration14 (see note below). As with all Stirling engines, the cycle has four phases: Expansion We start with the majority of the gas in contact with the warmer plate. Transfer Flywheel momentum carries the displacer downward, transferring the warm gas to the upper, cool end of the cylinder. Contraction Now the majority of the gas is in contact with the cool plate. Dr. Correction Dr. Ross Yoke Stirling. Andy Ross, a prominent Stirling engine experimenter, developed a Stirling engine using the linkage illustrated here. This engine is identical in operation to the two cylinder Stirling. In this illustration, the left cylinder is the hot cylinder.

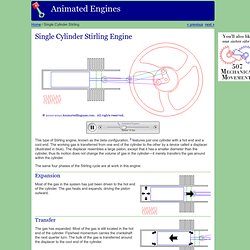

The linkage allows the engine to be more compact, and reduces side loads on the pistons and connecting rods (because their travel is almost linear). Note on the linkage In an earlier version of this page, I stated that Andy Ross invented this linkage, and cited Rizzo3 as my source. I suspect it is probably incorrect to say that Mr. Single Cylinder Stirling. This type of Stirling engine, known as the beta configuration,3 features just one cylinder with a hot end and a cool end.

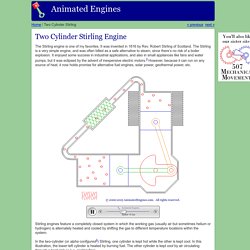

The working gas is transferred from one end of the cylinder to the other by a device called a displacer (illustrated in blue). The displacer resembles a large piston, except that it has a smaller diameter than the cylinder, thus its motion does not change the volume of gas in the cylinder—it merely transfers the gas around within the cylinder. The same four phases of the Stirling cycle are at work in this engine: Expansion. Two Cylinder Stirling. The Stirling engine is one of my favorites.

It was invented in 1816 by Rev. Robert Stirling of Scotland. The Stirling is a very simple engine, and was often billed as a safe alternative to steam, since there’s no risk of a boiler explosion. It enjoyed some success in industrial applications, and also in small appliances like fans and water pumps, but it was eclipsed by the advent of inexpensive electric motors.3 However, because it can run on any source of heat, it now holds promise for alternative fuel engines, solar power, geothermal power, etc. Stirling engines feature a completely closed system in which the working gas (usually air but sometimes helium or hydrogen) is alternately heated and cooled by shifting the gas to different temperature locations within the system.

In the two-cylinder (or alpha configured3) Stirling, one cylinder is kept hot while the other is kept cool. Expansion Most of the gas in the system has just been driven into the hot cylinder. Transfer Contraction. Stirling Engine Home Page -English- Welcome to Stirling Engine Home Page There have been viewers since 5 December 1995.

To Japanese Home Page Do you know about Stirling Engines? The Stirling engine was invented in 1816, before the gasoline and Diesel engines. This page is under construction 5 December 95. Stirling engines for beginners The Stirling engine's structure and history are examined in this session. View of model Stirling engines In this session, I am introducing some model Stirling engines. Let's build model Stirling engines On this page I offer plans for some easy to build Stirling engines.