Proxxon MF70 Miller CNC CONVERSION. Fundamentally this has to do two things, feed the Gcode to the miller controller and allow the miller controller to be set to a known reference point.

The first thing you must do is to edit the code so that it is looking for your named serial device, if you don’t do this it will default to the last device it sees in the list which is almost guaranteed to be wrong. Mantis 9.1 CNC Mill - Make Your Bot! The Mantis 9.1 design is a radical departure from version 8 and earlier.

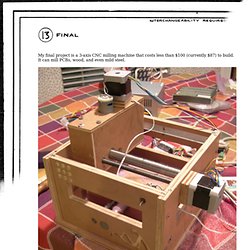

Most notably, the part count has been almost halved! The current design has 13 parts, all of which can be made with a handsaw and a drill press. Also, I've traded away my alignment free exactly-constrained design for extra stiffness. Several unsuccessful attempts to eradicate the last of the slop in the Z axis on version 8 lead me back to the world of over-constrained parallel rods. MAS 863 - David Carr. My final project is a 3-axis CNC milling machine that costs less than $100 (currently $87) to build.

It can mill PCBs, wood, and even mild steel. These PCBs were milled using the machine. The traces are 10-15 mils. The left and lower right boards were milled at approximately the same speed as the Modela. The upper right board was milled at a speed approximately 50% higher than that of the Modella. Translate. Azteeg G1-328P CNC Controller w/ 3AX Driver module. Description: The Azteeg G1-328 control module is part of the Azteeg Modular CNC controller system.It is designed to run small to medium scale 3 axis machines like CNCs, Laser cutters and other cartesian based bots.

It runs the free and powerful GRBL firmware and can be controlled by streaming g-code through USB. We combined the Arduino and the GRBL board to create the simple to use all-in-one controller. All the pins are available for expansion and utilizes the robust and proven stepper drivers from Texas Instruments. Installation is easy with the Azteeg G1-328 as all connectors are on the edges and utilizing terminal blocks for all wire connections.The G1-328 can be run directly with a single power supply with capability of accepting up to 30VDC.

Planet CNC. Fil A Mental. Projet Mantis: Une CNC DIY à moins de 150 euros. Ce projet a pour objectif de vous permettre de réaliser une CNC de table à un prix abordable.

Nous envisageons de proposer des kits qui seront assemblés lors d’un Workshop en un temps restreint (2 ou 3 soirées) avec les personnes intéressées. Les usinages complexes (axes, vis, bois découpé à la CNC) seront réalisés avant ce qui permettra de se concentrer sur le montage de la machine, les tests et la mise en route afin que la pédagogie prime sur la technique. Nous envisageons de procéder de la façon suivante : Réétude de Mantis pour l’adapter aux fournisseurs, unités et attentes européennesRéalisation d’un prototype fonctionnel, et mise au pointDémonstrations de la machine lors de soirées DIY dans divers lieux publics (Medialabs, collectifs d’artistes, etc..), lors desquelles nous prendrons les inscriptions pour le Workshop MantisPlanification du workshop,Achats matière première et réalisation des kitsWorkshop : probablement début 4e trimestre 2012. Eagle Pair® 190-540nm Standard Laser Safety Goggles.

Industrial 405nm 500mW laser module /Focusable/TTL [OL-405-500] - $119.99 : Zen Cart!, The Art of E-commerce. Precision by DefaultShapeoko. Pocket laser engraver. For the Arduino I started out writing my own software.

But while searching for a good way to control movement from the serial port I stumbled upon something called "Grbl ". This is a g-code interpreter with lots of nifty functions. As I already had everything connected to the Arduino I had to ether change my connections or change the software. Luckily it is easy to change control pins in the software. I did however have to download Winavr and then the code from github.com . Buy: Table croisée Proxxon(à coordonnées) KT 70 - Outillage - Outils électriques Proxxon - METIVIER MODELISME. Cardboard Solar CNC. Test #3 above: 1 inch/minute, letters 7/16 inch tall, kerf < 0.024 inch First, this 3 axis CNC gantry system was built on a lark, out of cardboard and mostly salvaged parts.

Building it kept me sane through late December - though how sane is it to build machine tools out of cardboard? Easy to Build Desk Top 3 Axis CNC Milling Machine. PCB Milling. PCB Milling Release status: Concept One obvious goal of making a RepRap replicatable is getting it to make it's own PCBs or other electronic circuitries.

PCB milling is one of the more promising ways of Automated Circuitry Making. Recent firmwares understand a pretty standard flavour of GCode, opening the door to a lot of toolpaths already existing. This page describes a few promising ones. Researchers have already milled out functional PCBs on the WolfStrap. (Should these be moved to Useful Software Packages ?) While a gazillion of softwares for creating and manufacturing circuits and PCBs exists, it was surprisingly difficult to find a working combination. All applications described claim to run on all major OSs: Linux, Windows, Mac OS X. PCB CNC. Aus Metalab, dem offenen Zentrum für meta-disziplinäre Magier und technisch-kreative Enthusiasten.

Introduction CNCs can facilitate in the creation of PCBS: Manual etching and then using CNC to drill automatically. Cutting out the board , to have round PCBs, or similar. Automated isolation routing: From a PCB some surface parts are milled away, so that the connection copper area are left isolated. Currently, all three steps are working on the Geilomat. For the isolation, there is the normal approach, where all contours of copper areas are milled. Some results are given in the soup of the Geilomat 0805 SMD resistors work fine, although the solder locations are not visible any more. Examples.