HeeksCNC « The Hell Ya Beller HeeksCNC can be finicky about profiles. Often I've found that a sketch which should be easily profiled won't generate any gcode at all. When I look in the console, I find an error like this File "/usr/lib/heekscnc/kurve_funcs.py", line 247, in profile raise Exception, "couldn't offset kurve " + str(offset_curve)Exception: couldn't offset kurve <area.Curve object at 0xb6f4bf2c> It most often happens when profiling inside a closed sketch where the radii is close to the diameter of the cutter. Recently I was profiling several cutouts that were exact copies of one another just rotated around a central point. It seems that the error is coming from the entry point. This won't work in every case, especially if the pocket is very close to the size of the cutter or made up of tight curves but for the most common cases it should work fine. My interests in CNC and machining developed over a period of years in a very organic way. But it doesn't work here. 5). The cutting process works like this:

My adventures in CNC robotics My adventures in CNC robotics Introduction I'm a computer geek by day, but I have always dreamt of something more than just writing code: I hoped to make things that interact with the physical world. To make it worse, I couldn't convince myself to take the now-popular route of buying the prefabricated robotics kits and putting them together in one of several predetermined ways. Ultimately, I just wanted to learn how to make stuff. Of course, that pipe dream soon collided with reality: I lived in Poland at that time - a country not known for its vibrant maker community - and did not even have access to a machine shop. I have a fairly neat daytime job and two kids, so I can dedicate just several hours every month to this hobby; with barely ~300 hours total, I still feel very much like a novice. Note: if you're more interested in the practical aspects of CNC manufacturing than in a personal story, check out my guerrilla guide to CNC machining instead. 2006: Baby steps And so I bought it.

EMC Documentation Wiki: Cam [Note: This page is currently being refurbished. The work includes additional entries, reorganization, addition of version/date stamping, addition of some annotation. About 1/3 of the work is done. Expect more changes.] Cam Post is an additional list of post-processors [opencam] is a wiki page about Open Source CAM (links, ideas etc.) that has no entries as of 2013.04.06 List of CAM references to toolpath generation algorithms and such is a CAx resource index for developers - CAD, CAM, CAE, etc. Links, versions and dates of releases checked 2013.04.06-08 CAD programs for Linux: programs to run windows software under linux: note: a few of the links are copied from

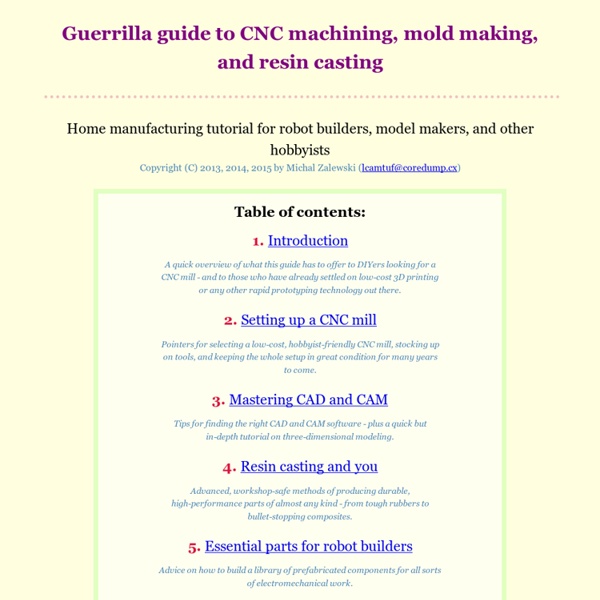

Guerrilla guide to CNC machining, mold making, and resin casting Guerrilla guide to CNC machining, mold making, and resin casting Okay, still interested? Let's dive in, then. The first "proper" section of this guide deals with shopping for a mill and understanding its operating characteristics; picking the appropriate cutting tools; and monitoring the performance of your setup to achieve perfect results every time. Again, if you're using another manufacturing process and are interested strictly in the CAD tutorial or the resin casting bits, feel free to skip ahead. 2.1. General purpose, benchtop-sized CNC mills start at around $600 and go up to $20,000 or so. There are numerous manufacturers of benchtop CNC mills around the world; some of the best-known brands include Roland DG, Sherline, Taig, and Syil. Of course, it is also possible to build your own machine from scratch. 2.1.1. This is perhaps the most fundamental quality of any CNC mill. In this machining mode, the machinable geometries are outlined here: 2.1.2. What to buy: do your own math.

Homemade CNC Router The Builder's Guide (FREE!) This guide is still under construction! Sections Introduction My Experience About Kits and Plans About This Guide The Guide Starts Here IntroductionSo you've decided to build a homemade CNC router or maybe youre just considering it, but where do you start? There are many advantages to owning a CNC router. Yes, you can build a CNC router that is just about as good as any other for a fraction of the retail price, and its not that difficult! There is also a great deal of flexibility when you design and build your own machine. There are many reasons people want to build their own homemade CNC router. My Experience When I first started to design and build my first homemade CNC router, I had it all figured out in about a day. Do I really need ball screws or will ACME screws work fine? Luckily, some of my questions I could answer with my mechanical engineering background. So I researched the internet. Maybe you dont want to design your own, but still want to build your own.

CNC 3020 router from eBay » Makerflux Earlier this year I had the urge to get back into an old hobby, Electronics! When I was younger and living with my parents I had my own workshop. In this workshop I would prototype some ideas on breadboard and when I was finished would design a printed circuit board. However I no longer live with my parents and have no access to a workshop. PCB etched via CNC After some research on Google I discovered that it’s possible to etch a copper clad board using a CNC router. Trying to find a local supplier for such a small CNC router was actually quite hard. It turns out that these cheap CNC routers are actually great value, but with the value does come some compromise. I should say that the majority of hobby CNC enthusiasts recommend self build. I placed my “Buy It Now” order on a Monday morning for £415 plus delivery, which is stated was shipped from within the UK (Where I live). The first cut The instructions that are supplied are in English, but you can tell it has been translated.

3 Axis System Kit 3 Axis System Kit (1) XS-3525/8S-3 Stepper Motor Driver Board and IDC26-DB25 cable (3) 269 oz.in. Nema 23 Double Stack/Double Shaft Bipolar Stepper Motor (1) 24VDC/5.0A Power Supply (Switch selectable betrween 110VAC & 220VAC) with 120VAC Power Cord, and 24VDC Pigtail (1) 2.3" X 2.3" X 1" 24VDC Fan with 2-pin Molex conenctor connection example. click image to enlarge Drive Setup Instructions All for $265.00 plus USA Shipping Flat $12.00 via USPS Priority Mail (other countries e-mail for shipping cost) What you will also need: Order HERE

CNC Router Plans: Download free CNC router plans CNC router plans are a great starting point for anyone wanting to build a CNC router. They give valuable insight on how these machines work. Many of us are very visual people and it helps to see examples of these machines laid out on paper. You may prefer to design and build your own machine. This is why we want to provide you with as many free plans and blueprints as possible. Even if you decide to use plans, we strongly suggest you read through the Builders Guide There you will find in depth information regarding all the components and their function. For now, feel free to check out the plans below. JGROs Design This design is very popular among the DIY CNC router community. Download JGROs Design in PDF format Download JGROs Design in DXF format Please note, that by downloading this plan, you are under the agreement that they are not to be resold or used for commercial purpose. Joes 2006 R-1 Design This is another very popular design. Download JOEs 2006 design in EASM format

Tweakie.CNC - CNC Homebuilt router, mill, engraver, vinyl cutter, hobby ... Vectric - CNC Software Solutions - Wood Carving - Engraving - Signmaking - Routing - Machining