Perforated Panels from Ductal® Durable concrete uses graphene particles to fend off water and cracks. As scientists work to shore up the strength and durability of concrete, it mightn't come as a huge surprise that the wonder material graphene is proving to be a promising additive.

As the world's strongest artificial material, it may have a lot to offer the world of construction, and the latest example of this comes from Northwestern University researchers, who have developed a novel form of graphene-infused cement that is highly resistant to water and cracks. As the key ingredient in the production of concrete, the world's most widely used material, cement has a massive environmental footprint, accounting for around eight percent of global greenhouse gas emissions. Cement-free concrete recipe bonds sand using alcohol. Concrete is the most commonly used building material in the world, but unfortunately the cement used to make it carries quite a carbon footprint.

Now, scientists at the University of Tokyo have created a cement-free alternative that directly bonds sand particles together using a reaction between alcohol and a catalyst. Concrete is made up of an aggregate material, usually sand and gravel, and cement, which acts like glue to hold it all together. Portland cement is the most common type, but making it is a pretty environmentally unfriendly affair – between the high heating temperatures and the limestone outgassing, about 1 kg (2.2 lb) of carbon dioxide is produced for every kilogram of cement.

Considering just how much of the material is made every year, cement production accounts for around eight percent of global CO2 emissions. Concrete Canvas® - The innovative GCCM technology made in the UK. Why Roman concrete is stronger than it ever was, while modern concrete decays. 'silica plastic block' is a sustainable brick made from recycled sand + plastic waste. MIT researchers find new approach suggesting path to emissions-free cement. Cement is the world’s leading construction material — but did you know producing it is one of the major sources of greenhouse gas emissions accounting for about 8 percent of all such releases?

This means that if cement production were a country, it would be the world’s third-largest emitter. aiming to solve this problem, a team of researches at MIT has come up with a new way of manufacturing emission-free cement that could eliminate the total emissions while also making other useful products in the process. ‘about 1 kilogram of carbon dioxide is released for every kilogram of cement made today,’ comments yet-ming chiang the kyocera professor of materials science and engineering at MIT.

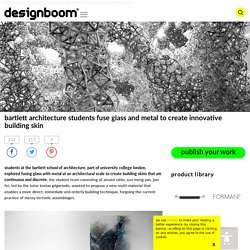

Bartlett architecture students fuse glass and metal to create building skin. Students at the bartlett school of architecture, part of university college london, explored fusing glass with metal at an architectural scale to create building skins that are continuous and discrete. the student team consisting of ainaini rahin, sun meng yan, jian fei, led by the tutor kostas grigoriadis, wanted to propose a new multi-material that enables a more direct, immediate and orderly building technique, forgoing the current practice of messy tectonic assemblages. close-up view of metal and bullseye glass frits functionally graded material study model. gradient of glass and metal fluids that fuse within a certain period of time. one of the main issues the students encountered when fusing glass with metal in an architecture scale was the firing process and keeping the gradient accurate when following the computational simulation results.

Frontal and side views of the functionally graded material model where the exterior glass skin was topologically optimized. Old glass may find use in new, better concrete. MIT researchers discover way to move 25 ton stones with only their hands. Cambridge-based firm matter design has unveiled research on seemingly ‘weightless’ concrete forms that can be easily moved. realised in collaboration with construction-research company CEMEX global R&D, the pair have discovered a way of rotating mammoth stones that would otherwise rely on cranes or heavy equipment. images courtesy of matter design.

Australia's tallest timber building makes a towering case for eco-friendly construction. Fracture-resistant cement inspired by the spines of sea urchins. The natural world is a constant source of inspiration for scientists and engineers.

The latest biologically influenced innovation comes from a team of German researchers who developed a new type of stronger cement inspired by nanostructures found in sea urchin spines. The team was inspired by the structural resilience of sea urchin spines, which are primarily made up of a brittle material called calcite. Yet despite the nature of calcite, the spines are incredibly durable because of a nano-level, brick-and-mortar style architecture.

World's first Biological House is built from farming waste. The Biological House was created by a multidisciplinary team involving more than 40 partners, including Copenhagen-based design firm Een TIl Een, sustainable architecture firm GXN, wood-treatment company Kebony and the Danish Ministry of Environment.

To begin, GXN teamed up with partners from the Danish farming sector to gather biomaterials that would otherwise be burned for energy, things like grass, straw, tomato stems and seaweed. These were then combined into composites to maximize their strength and pressed into boards for cladding. Kebony then treated these softwoods by applying heat and a bio-based liquid. This polymerizes the cell walls within the wooden material, causing it to take on the properties of tropical hardwood along with a pleasant rich-brown color, which develops a silver-gray patina after exposure to the sun and rain. Further using of sustainable construction materials, the Biological House negates the carbon emissions that would arise from burning them.

The problem with reinforced concrete. By itself, concrete is a very durable construction material.

The magnificent Pantheon in Rome, the world’s largest unreinforced concrete dome, is in excellent condition after nearly 1,900 years. And yet many concrete structures from last century – bridges, highways and buildings – are crumbling. Many concrete structures built this century will be obsolete before its end. Given the survival of ancient structures, this may seem curious. The critical difference is the modern use of steel reinforcement, known as rebar, concealed within the concrete. While repair may be justified to preserve the architectural legacy of iconic 20th-century buildings, such as those designed by reinforced concrete users like Frank Lloyd Wright, it is questionable whether this will be affordable or desirable for the vast majority of structures.

Steel reinforcement was a dramatic innovation of the 19th century. High hopes for tiny house made from hemp. As any good hippy will tell you, the cannabis plant isn't only good for getting stoned.

Hemp has been used for thousands of years for all kinds of stuff, including making rope, clothing, and even cars. With this in mind, Albany, NY-based Green Built has high hopes it can bring cannabis construction into the US mainstream with its hemp-based tiny house. Joking aside, it's important to note that hemp construction isn't new or even unusual outside the US, and makes sense as a sustainable building material. Green Built aims to use Hempcrete (essentially a mix of hemp, lime and water) to build its tiny house. Seeds planted for London's first wooden skyscraper. Researchers at Cambridge University's Department of Architecture, working alongside PLP Architecture and engineering firm Smith and Wallwork, have presented conceptual plans for a wooden skyscraper to London mayor Boris Johnson.

If it went ahead, the timber tower would be the tallest of its kind in the world. While it's too soon to comment as to the project's chances of actually getting built, the tower is slated for London's Barbican Estate and would, along with nearby mid-rise terraces, provide 1,000 much-needed new homes and around 1 million sq ft (304,800 sq m) of residential floorspace for England's capital. More impressively still, the 80-story building would rise to a total height of 300 m (984 ft), making it the second-tallest building in London (after the Shard), and the tallest timber skyscraper in the world.

Today's CO2 may become tomorrow's concrete. As carbon emissions continue to rise and cause the planet to warm up, we need to find ways to reduce them. Capturing carbon at the source of its emission is one of the solutions, but there is still the problem of storing all the carbon sucked out of the atmosphere. If that captured carbon could be put to good use, then perhaps we could have the perfect capturing system in place. This is the line of thinking that researchers at University of California (UCLA) are currently pursuing, and they have some big plans for all that carbon: turning it into concrete. Step-by-Step Earthbag Building. This Instructable explains each main step of construction for building vertical earthbag walls.

Videos on my Earthbag Natural Building YouTube channel demonstrate the process. For those who don’t know, earthbag building uses polypropylene rice bags or feed bags filled with soil or insulation that are stacked like masonry and tamped flat. Barbed wire between courses keeps bags from slipping and adds tensile strength.

The final plastered walls look just like adobe structures. How to Build a Dirt Cheap House in 4 Steps. Ever wonder how to build a simple home for very little money, without going into debt? The key is to use low-cost, locally available natural materials such earth, small diameter wood and straw to keep expenses to a minimum. The real fun is incorporating all of these methods into an optimum, comfortable, affordable home. Our earthbag projects have confirmed what I’ve known for a long time – that building at $10/sq.ft. (materials only) or thereabouts is possible.

Other aspects of earthbag building — strength, durability, sustainability, etc. — are all important. A big reason for the growing popularity of earthbag building is its low cost. BioSkin defies urban heat island effect to help keep buildings cool. The BioSkin that coats the NBF Osaki Building in Tokyo integrates evaporative cooling to keep its surface temperature down Image Gallery (9 images) The urban heat island effect, whereby the high concentration of heat-retaining concrete and bitumen causes metropolitan centers to be significantly warmer than the rural areas surrounding them, is a common problem around the world.

Hardscaping 101: Gabion Walls: Gardenista. Older. Zeoform: The eco-friendly building material of the future? Zeoform promises a recyclable, low carbon-footprint building material that's as strong as ebony Image Gallery (4 images) Expert Advice: American-Made Building Essentials, Courtesy of Lake. Older. Wood poised to scrape the sky. Ancient Roman Concrete Is About to Revolutionize Modern Architecture. Umbrella facade designed for Shanghai complex. The new screen will feature steel umbrellas that can be individually opened and closed and used to manage light levels within the complex (Image: 3Gatti) Image Gallery (9 images) 10 Favorites: Full Height Sliding Doors and Partitions.

Affordable net zero: foam in, air conditiong out. By prioritizing energy minimization, and taking a pragmatic approach to materials and insulation, client Dr. Modernizing the mashrabiya: Smart-skinned Al Bahar Towers near completion. Glass-skinned steel-frame skyscrapers have many advantages.