Natural Building Workshops. April works on some of the last remaining joints before the timber frame assembly I think I’ve realized that the excitement of timber framing can be represented by a curve.

If the x axis on a bar graph represents time, and the y excitement, the line climbs and rises from left to right. The entire process is gradually more invigorating and interesting as you proceed on a project. [click to continue…] If you enjoyed this post, get free updates by email or RSS. Experience sustainable living at Dancing Rabbit Ecovillage this year Well, that came up fast. There are a number of ways to visit Dancing Rabbit, but if you think you might be interested in living there one day, the visitor program is your best bet. [click to continue…] Jacob tests out the 16″ Makita circular saw on an end cut Things are progressing smoothly for us here in Nacogdoches. [click to continue…] April gets her set of timber frame plans ready to go We’ve made it to Texas.

[click to continue…] [click to continue…] Farmer Builds A House For Just £150 With Cob & Salvaged Items. Michael Buck used only natural materials or unwanted items to build 'cob house' at bottom of his gardenHe said he wanted to challenge the notion that paying for a house should take a lifetimeHe is now renting out the property to a worker on a neighouring farm, who pays for her lodgings in milk By David Wilkes for the Daily Mail Published: 11:32 GMT, 25 November 2013 | Updated: 02:06 GMT, 26 November 2013 It looks like something straight out of Middle Earth – and the story behind it is almost as fantastical.

This cottage cost just £150 to build, using only natural or reclaimed materials, and is now rented out for a fee of fresh milk and cream. And with no mains electricity, gas or water, the bills don’t come to much either. You Can Build This Cob House for $3000. When designing my cob house, it was a goal to keep building costs very low and to obtain as many building materials as locally as possible, especially natural (of course) and reclaimed supplies. Few materials were purchased new, and about as few are synthetic. In this very detailed entry, Recipe for Building a Cob House , you can learn what it took to build my cob house for about $3000.

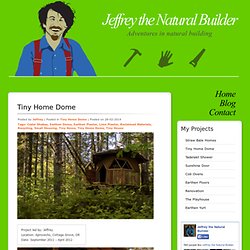

You’ll also learn exactly how much cob I made (all by foot!) , and specific amounts of material that went into the construction. Please read ahead if you have any interest in building with cob! Tiny Earthen Home Dome. Project led by: Jeffrey Location: Aprovecho, Cottage Grove, OR Date: September 2011 – April 2012 Reclaimed timber ceiling feature, surrounded by earthen plaster The project began with an idea: by reducing the size of a house, we actually increase the space we live in.

Having a smaller home forces us outside and into nature. My aim was to make a well built cabin cheaply; using material destined for the landfill as much as possible.I feel that much of the western world has become a ‘throw-away’ society. No longer do we repair our belongings when they wear out or break, but instead we thrown them away and buy new ones.

I wanted the cabin to be small, with room enough for only a bed, desk and small wood stove for winter heat. I decided on the geodesic dome as the shape for my cabin. To begin the project I constructed a nine-foot, ten sided deck using wood salvaged from a torn down shed and concrete pier blocks that were found on site. The skeleton of the dome. Bamboo, Wattle & Daub Yurt. Posted by Jeffrey | Posted in Earthen Yurt | Posted on 23-06-2012 Tags: aprovecho, bamboo, daub, earthen, kiko denzer, natual building, reciprocal roof, wattle, wattle and daub, yurt Project led by: Kiko Denzer Location: Aprovecho, Cottage Grove, OR Date: August 2012 This earthen yurt was built as part of the ‘sustainable shelter series’ at Aprovecho. The yurt is made from site harvested bamboo, lashed together using recycled bailers twine.

It features a reciprocal roof, meaning that every beam is supported by all the beams in front, and in turn supports all behind it. The beauty of the yurt is the circular space it contains, we live so often in box shaped houses with box shaped rooms. The project made me think a lot about the underused power of the circle in architecture and society.

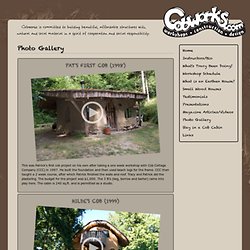

The bamboo framework. Cob House Photo Gallery. Pat's First Cob (1998) This was Patrick's first cob project on his own after taking a one week workshop with Cob Cottage Company (CCC) in 1997.

He built the foundation and then used beach logs for the frame. CCC then taught a 2 week course, after which Patrick finished the walls and roof. Tracy and Patrick did the plastering. The budget for the project was $1,000. Hilde's Cob (1999) The major construction of this cob was completed in the summer of 1999. Garden Cob (2002) Elke and Patrick built the Garden Cob during an 8 week apprenticeship course. The Cob House Collection At Natural Homes. Cob Houses Around The World. Cob House Journal Photo Gallery by Hap Mullenneaux at pbase. A Cob "Shed" A Beautiful Cob House In Oregon, USA. A Bathroom Mosaic In A Cob House In Oregon, USA.