Fuel3D: The low-cost, high-quality 3D scanner. Re3D. The Buccaneer® - The 3D Printer that Everyone can use! by Pirate3D Inc. Manufacturing timeline and Stretch goals sections are at the very end for those who just want to go there.

FAQ is also at the back, do check it out in case the questions you have are already answered there. Hi everyone! We have had many requests to see the internals of our 3D printer while it is printing. We ripped out the mechanics from our final casing and placed them into our prototype casing (which is transparent) for all of you to see! You may notice the internals are slightly different from our main video and the reason for this is the progress we have made from the time we applied for Kickstarter until the day it is launched. It's a bit messy because our prototype box doesn't have the compartments for proper storage but it looks great either way.

The item printed is the Cute Octopus from Makerbot, Created by Jason Bakutis and is a creative common. The Peachy Printer - The First $100 3D Printer & Scanner! by Rinnovated Design. Below is a detailed video explaining how the Peachy Printer works through explanation and demonstration!

The peachy printer is a Photolithographic printer. That means it uses a controlled beam of light to cure light sensitive resin into hard objects. The peachy moves a laser beam along the X and Y axes to create the shape of the object, while using a drip system to control the level of the resin on the Z axis which determines the height of the object. ZPrinter® 650. FORMIGA P 110 - laser sintering 3D printer for rapid prototyping – EOS. FORMIGA P 110 is a flexible, cost-efficient and highly productive system for the Additive Manufacturing of polymer parts.

This compact system is ideal as an entry into Additive Manufacturing, for example for cost-efficient small series production, customised products with complex geometries and rapid prototyping applications. Without requiring tools, the system makes direct use of digital CAD data to produce polymer parts of the highest surface quality to a maximum construction height of 330 mm. Innovation Additive Manufacturing of polymer products directly from CAD data within just a few hours Cost-efficient, batch-size appropriate production Flexible balancing of component requirements (mechanical criteria, surface quality, consistency of form, etc.) with the greatest possible cost efficiency through the use of suitable EOS parameter sets Quality Sustainability Efficiency Flexibility.

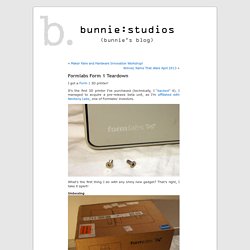

Full scale 3D Printer. Maplin Electronics. Voxeljet. Welcome to D-Shape. Materialise. Formlabs Form 1 Teardown. I got a Form 1 3D printer!

It’s the first 3D printer I’ve purchased (technically, I “backed” it). I managed to acquire a pre-release beta unit, as I’m affiliated with Neoteny Labs, one of Formlabs’ investors. What’s the first thing I do with any shiny new gadget? That’s right, I take it apart! Unboxing The complete Form 1 kit consists of three boxes: the printer (shown above), bottles of liquid photocurable resin, and a cleaning station.

Frequently asked questions on 3D printing. What is 3D printing?

3D printing is a prototyping process that makes it possible to create an actual object from a 3D file. The object is formed by applying successive layers of solid material. Making a white plastic object with the Eos machine: Making a coloured object with the Zcorp machine: What software should I use if I’m a beginner in 3D design? - Google provides a free, easy to use application called Google Sketchup . Free 3D Models for 3D Printing. Submit additions and corrections to the 3D Printing Directory.

Thingiverse - Digital Designs for Physical Objects. Stereolithography. An SLA produced part Stereolithography (SLA or SL; also known as optical fabrication, photo-solidification, solid free-form fabrication and solid imaging) is an additive manufacturing or 3D printing technology used for producing models, prototypes, patterns, and production parts up one layer at a time by curing a photo-reactive resin with a UV laser or another similar power source.[1] History[edit] The term “stereolithography” was coined in 1986 by Charles (Chuck) W.

STL (file format) Example of STL vs CAD format STL (STereoLithography) is a file format native to the stereolithography CAD software created by 3D Systems.

STL is also known as Standard Tessellation Language.[1] This file format is supported by many other software packages; it is widely used for rapid prototyping and computer-aided manufacturing. STL files describe only the surface geometry of a three-dimensional object without any representation of color, texture or other common CAD model attributes. The STL format specifies both ASCII and binary representations. Binary files are more common, since they are more compact.[2] Baby's life saved with groundbreaking 3-D printed device that restored his breathing. Every day, their baby stopped breathing, his collapsed bronchus blocking the crucial flow of air to his lungs.

April and Bryan Gionfriddo watched helplessly, just praying that somehow the dire predictions weren't true. "Quite a few doctors said he had a good chance of not leaving the hospital alive," says April Gionfriddo, about her now 20-month-old son, Kaiba. "At that point, we were desperate. Anything that would work, we would take it and run with it. " They found hope at the University of Michigan, where a new, bioresorbable device that could help Kaiba was under development.

Green and his colleague, Scott Hollister, Ph.D., professor of biomedical engineering and mechanical engineering and associate professor of surgery at U-M, went right into action, obtaining emergency clearance from the Food and Drug Administration to create and implant a tracheal splint for Kaiba made from a biopolymer called polycaprolactone. "It was amazing. 3D-Printed Skull Implanted in American Patient’s Head : D-brief. There is no shortage of new and interesting uses for 3D printing technology.

This week one more has been added to the list, and it’s pretty darn impressive: replacing 75 percent of a patient’s skull with a 3D-printed implant. The skull implant was approved by the FDA last month, and the surgery itself took place on March 4, as reported by Tech News Daily. The implant was made from a type of thermoplastic called polyetherketoneketone (PEKK).

This material is moldable above a certain temperature, and returns to a solid state when it cools. Unlike most plastics, thermoplastics’ long polymer chains do not break down during the melting process. TED: Printing a human kidney. 3D printer makes tiniest human liver ever - health - 23 April 2013. Video: 3D printer makes world's smallest human livers Lab-grown livers have come a step closer to reality thanks to a 3D printer loaded with cells (see video above). Created by Organovo in San Diego, California, future versions of the system could produce chunks of liver for transplant. The mini-livers that Organovo made are just half a millimetre deep and 4 millimetres across but can perform most functions of the real thing. To create them, a printer builds up about 20 layers of hepatocytes and stellate cells – two major types of liver cell. Crucially, it also adds cells from the lining of blood vessels.

Existing liver assays, based on single or double layers of cells, only last two days and don't have the same range of functions as the micro-discs. Liquid Scaffolds From A 3-D Printer. Ekso Bionics - An exoskeleton bionic suit or a wearable robot that helps people walk again. 3D Printing Mechanical Hands. 3D-printed baby fetus is more impressive than an ultrasound.

Maybe you could wear it as a pendant. (Credit: Fasotec) Congratulations, you're expecting! Now, how about turning that great news into something that will fit on a keychain. It comes in this attractive gift box. (Click to enlarge.) Japanese company Fasotec will make a miniature 3D replica of your fetus and hand it off to you in a lovely jewelry box for about $1,280. Fasotec calls the custom product "Shape of the Angel," an optimistic view that precedes the reality of the tantrums and eventual teenage angst you'll have to contend with as a parent. Of course, you can't just pop down to the local 7-Eleven and pick one of these up. White resin replicates the shape and position of your baby and clear resin represents the womb. If you thought baby stories were embarrassing, just wait til mom and dad whip out your fetus model to show your date when he comes to pick you up for prom. (Via New Launches )

Working gun made with 3D printer. 6 May 2013Last updated at 06:38 GMT By Rebecca Morelle Science reporter, BBC World Service, Texas The BBC's Rebecca Morelle saw the 3D-printed gun's first test in Austin, Texas The world's first gun made with 3D printer technology has been successfully fired in the US. The controversial group which created the firearm, Defense Distributed, plans to make the blueprints available online. The group has spent a year trying to create the firearm, which was successfully tested on Saturday at a firing range south of Austin, Texas.

Anti-gun campaigners have criticised the project. Europe's law enforcement agency said it was monitoring developments. Victoria Baines, from Europol's cybercrime centre, said that at present criminals were more likely to pursue traditional routes to obtain firearms. 3Doodler: The World's First 3D Printing Pen by WobbleWorks LLC.

Gilles Retsin of Softkill Design on 3D printed houses. Interview: earlier today, London studio Softkill Design unveiled plans for a 3D printed house. We spoke to Softkill's Gilles Retsin about the viability of printed architecture and how he intends to print a plastic dwelling in just three weeks. "When we started this research, it was a kind of science fiction," he says. "It's not actually that far off any more.

" Amy Frearson: Tell us how the project came about. Gilles Retsin: The prototype, ProtoHouse 1.0, started as academic research at the AA Design Research Lab. So the ProtoHouse 1.0 was the first prototype for a 3D printed building.