Simple Boiler Design. Calculations.

Some calculations were made on the proposed copper tube to see if it was suitable to be made into a pressure vessel and to ensure a safe design. The formula used was P = (2T x s) / D Where : P = working pressure T = Thickness of the copper tube (inches) D = Internal diameter of tube (inches) s = Maximum safe stress of copper ** Therefore : P = (2x0.047" x 2500) / 2" = 118 psi So the 1.2mm thick, 50mm diameter copper tube could be used up to 118psi and still be within a tenth of the copper tensile strength. The engine was found to perform best on 20 - 40 psi, any more than this and the cylinder was lifted from the port face. ** Copper tensile strength taken as 25,000 pounds force. ** Chosen factor of safety = 10, so Copper strength reduced to 25,000 / 10 = 2,500 pounds.

It was planned to make the boiler end plates from the same thickness of copper, with a central stay through the middle, also made from copper. Working pressure 40psi. Copper tensile strength 25,000 pounds force. ModelBoilers. Simple Boiler construction. Copper boiler scratch build project. Keep brainstorming guys!

More info: The gas jet housing had two 1/4" holes. Now it has four. The burner tube ran the entire length of the flue. Now it runs 3/4 of the way because I shortened it. I tried covering most of the slits, and having about 1/4 as many open as originally. I moved the gas jet nozzle in and out of the housing. I tried with the stack on, and off. I lit the burner tube outside the boiler, adjusted the gas jet nozzle for a perfect blue flame, and then inserted it into the flue.

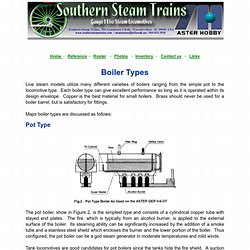

I removed the burner tube while the flame was burning out the opposite end, and none of the slits were lit as I pulled it out. In every situation and adjustment, a flame inside the flue doesn't exist. Little%20Steamers. Boiler Types. The Locomotive type boiler, shown in Figure 8, consists of a copper barrel and an outer and inner firebox attached to the rear of the barrel.

Perfectly round pressure vessels carry pressure loads by developing hoop tension stresses in the wall of the boiler. In this case, there is no tendency for the walls to bend. Boiler making material? - myLargescale.com - Forums - G Scale Forums - Live Steam. Little Steamers and Their Boilers. Little Steamers and Their Boilers(by Jack Wheldon, Burbage, England) The following text and diagrams first appeared as a series of two articles in the American magazine "Garden Railways" (July-August and September-October 1998 numbers) and are reproduced here by kind permission of the magazine's editor, Marc Horovitz.

Part 1: Theory Background When a small scale loco builder starts work on the generating department that is, on boilers -he or she faces a parting of the ways. The Hobbyist's Machine Shop – Blog. I occasionally read about the concern with the miniature steam boilers we use in our live steam hobbies.

There is some concern about these devices being potential BOMBS. I purposefully emphasize the word bombs. Scare writers also like to use the word EXPLODE. Again emphasis added. These are nice scary words designed by writers and editors to grab your attention. We live in a dangerous world. It’s a matter of perspective. Copper is the preferred construction material in miniature boilers. Copper boiler failures are not immediate explosions in the sense of a black powder pipe bomb or even a paper firecracker. What actually happens is a relatively slow build-up of pressure over many minutes of time. In properly designed boilers we purposely design the weakest point to be the pressure relief valve(s). When superheated water is suddenly reduced in pressure (because of the split boiler shell or opening of the relief valve), it creates a super hot jet of steam.

Back to amateur built boilers. Copper boiler scratch build project.