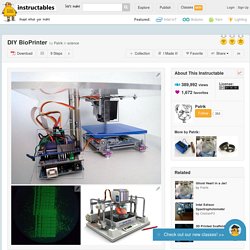

DIY BioPrinter. We started out by messing around with an old inkjet printer that we literally saved from a sidewalk somewhere.

There's already plenty of interesting things you can do with an low-end off-the-shelf inkjet printer, but they do have some limitations, which we'll get into in the next Step (or skip straight to Step 3 for how we built our own bioprinter from scratch, that you can see in the first picture above). Undressing the Printer We disassembled an abandoned HP 5150 inkjet printer for use as a bioprinter. Just rip off all the plastic covers you can find, but make sure you can still operate the reset buttons etc. on the front panel. There's a little momentary switch that senses whether the cover is open. There's also a momentary switch inside the paper handling mechanism that senses whether paper has been loaded. Fused Deposition. Anubis 3D, 3D Printers serving Mississauga and Canada. From 3D Printing to Protoyping and design. - Anubis 3D - Design for a New Dimension.

Business Situation: Development of the “Anubometer” prototype.

A solids flow-meter using a vision system. The prototype assembly was ready to be displayed at a potential customer’s site for technology assessment within 2 weeks, except the support bracket for the LEAD pattern projector was missing. Technical Situation. MakingFoamFly. My version of the LYMAN FILAMENT EXTRUDER by bottleworks. These files are posted to give some ideas to those who are making an extruder.

This is by no means a "how to" or anything of the sort. The STL and sketchup files are included. I hope some will find the data useful. I'll add on to why I made the changes that I made after some sleep... I've added a photo of the Rev B hot end. Reprap » Githubiverse – A Github Pages Template for 3D Printing Projects. I’m a big fan of github, and I think it provides an excellent set of resources for hosting 3D printing projects.

Recently I had the idea that it would be useful if these projects were able to utilise Github Pages to provide a project landing page, showing similar information to that found on Thingiverse. Project Spaghetti Dinner. Materials Blog by Inventables. Basic Resistor Sensor Reading on Raspberry Pi. We've already covered how to use an Analog-to-Digital Converter chip with a Pi.

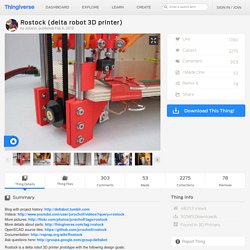

These chips are the best way to read analog voltages from the Pi. However, there's a way to read many sensors without an ADC! By measuring the sensor as a resistor that is used to 'fill up' a capacitor, we can count how long it takes. It's not nearly as precise as an ADC and its a little flakey (since it depends on the Pi timing itself which can vary based on how 'busy' the computer is) The way we do this is by taking advantage of a basic electronic property of resistors and capacitors. Rostock (delta robot 3D printer) by Johann. Blog with project history: Videos: More pictures: More details about parts: OpenSCAD source files: Documentation: Ask questions here: Rostock is a delta robot 3D printer prototype with the following design goals: Build volume: 8x8x16 inches or 200x200x400 mm Footprint: 12x14 inches Print surface: 8x8 inches heated glass which never moves Mass of end effector with two hotends: less than 150g Positioning speed: 800 mm/s in all 3 directions Positioning accuracy: at least 30 steps/mm in all 3 directions Simplicity: fewer than 200 parts (not including washers, nuts and SMD-mounted electronics) Hardware cost: less than $500 USD Inspiration: search YouTube for "flexpicker" or "adept quattro".

Closest ancestor:

Theory. Exploring the wonders of 3D printing. Ultimate Guide to opening & profiting from Shapeways shop. How Products Are Made. Metals. A Swedish hackerspace in Halmstad. Fabbers@UW. My contribution to the increasing entropy and eventual heat death of the universe. The 'Art' of failure - When 3D prints go wrong and lessons from failure. Everyone has the odd bad print or failure that results in something interesting or frustrating depending on how urgently you needed the part to print.

Here are some of my failures and tips on how to avoid them and lessons learnt. (And if you can help me explain what happened last weekend to one of my PLA filament rolls I would be most interested - see at the end). It may sound odd, but it's really essential that you fail when doing 3D printing, It tells you so much about your machine, the boundaries you can operate in and how good or bad things can be.

If all you do is print with safe settings or never play with the electronics or firmware the you are missing so much of this wonderful project. You also can't just be told what settings to use and how fast to run etc. you need to feel how your particular machine works and what it's capable of. Unfold ~fab. Second post today, I'm catching up while sitting next to a humming Rapman printing a batch of ceramics.

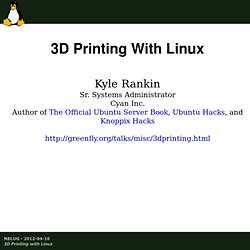

Unfortunatly I need to keep an eye on the flowrate and correct pressure or printhead speed every few minutes. More on that in another post. Luckily the Rapman has manual controls. turns head-adjusts speed-back to typing. Yesterday I was going through the excellent documentation of the frostruder at Makerbot. Unfold ~fab. 3D Printing with Linux. What is 3D Printing?

Types of 3D PrintersLaser-cut wooden box 3D printersRepRap familyOthersLinux 3D Printing SoftwareFirmwareSlicersUser InterfaceFirmware CalibrationSlicer CalibrationABS vs. PLA plasticCAD Software. G Codes - ReplicatorG. Draw Freely. Frequently asked questions. General What is Inkscape?

Inkscape is an open-source vector graphics editor similar to Adobe Illustrator, Corel Draw, Freehand, or Xara X. What sets Inkscape apart is its use of Scalable Vector Graphics (SVG), an open XML-based W3C standard, as the native format. What are vector graphics? In contrast to raster (bitmap) graphics editors such as Photoshop or Gimp, Inkscape stores its graphics in a vector format. Freeside Atlanta: Making print cartridges for a Z400/Z402 3D printer. One of the costs of running an inkjet based 3D printer is that the cartridges have to be replaced on a regular basis. The Z400 and Z402 use Canon BC-20 ink cartridges which are readily available.

There are currently two known ways of making these cartridges ready for the printer. The first method is to cut the cartridge in half, remove the foam inside, cut a Blue Falcon BD-50 Centrifuge tube in half, and epoxy it and a small O ring to the reservoir at the bottom of the cartridge. This is how the cartridges that are sold by Z Corp are made. An alternative method is two drill two holes in the cartridge, epoxy down some type of barb, and flush the cartridge.

I've done both methods, but always had trouble getting a good seal with the first method. First, the Canon BC-20 print cartridge: 3D Printer. One step conversion of an image to gcode for Makerbot Unicorn and Reprap style 3D Printers. How to take an image like this: and in one step generate the gcodes required to do this: All credit for cad.py goes to the original creator Neil Gershenfeld of MIT Center for Bits and Atoms and David Carr of Make Your Bot who optimised the code that is in use here. By attaching a pen to a 3D printer it is easy to turn it into a basic pen plotter. However producing the G-codes require to drive your 3D printer as a pen plotter can be anything but easy. This short guide seeks to change that. Of these options I believe cad.py is by far the simplest as once it is setup you can convert an image directly to gcode in one go with one program and with out the need to use a command prompt.

Download the following software for your respective OS. 1. python-2.6.5.msi (Python 2.6 Website)2. numpy-1.6.1-win32-superpack-python2.6.exe (Numerical Python)3. Run the Cad.py that suits your hardware. When the program begins do the following to test your setup: Building the router copier. Router mount and carriage The router mount and carriage provides three degrees of freedom. The carriage rolls side-to-side on a steel pipe, but also tilts on that pipe. A thinner shaft (highlighted in red) also allows the router and follower to pivot.

The most complicated parts for the carriage are the "side arms". Customize and create 3D printed products. Welcome to the Future of Stuff. 3D Paint - ECE 4760. For our final project in ECE 4760, we designed and implemented a three-dimensional paint program consisting of hardware, a microcontroller, and a PC running MATLAB. All three modules strongly interacted to allow the artist to wave a pen around in space and see their movements translated in real time to various projections on the computer. An ATmega644 microcontroller calculates the time delay from the pen to three known points and communicates these values continuously to a PC running MATLAB via a serial port. MATLAB then translates the delay information to real xyz-coordinates and displays the data in various forms on a fully functional GUI.

The artist can additionally use the pen as a camera to look around the design space. Blog: Colour mixing. Here is Myles's latest mixer extruder. Homecmos - DIY CMOS and MEMS fabrication. Blog: More Printed Circuitry. Makible - Dream it, Fund it, Make it, Move it - Makible. Machine. Df1_loom.pdf (application/pdf Object) Glaskolben Blown Glass Ornament Kit - Glass Blowing Kits. Omnibot build log. My adventures in CNC robotics. My adventures in CNC robotics Introduction. Guerrilla guide to CNC machining, moldmaking, and resin casting, volume I. How_to_build_a_multimachine. Basic Motor Theory. Basic Motor Theory Introduction. Make Your Own Machinable Wax. Cambridge University Engineering Department - Qi Pan. HiTorque 7x12 Mini Lathe. The LittleMachineShop.com HiTorque Mini Lathe is the best in its class.

It has the most power, most torque, and a longer center distance than other lathes in its class. The 500 Watt brushless spindle drive motor provides tremendous low-end torque. Will's Fabber Blog. Notes on Sprockets and Chains. Appendix 22: Hans Goldschmidt and his Shopsmith. RepRapWiki. Print Your Own 3D models (by @baekdal) #trends - StumbleUpon. Fab@Home:Materials - Fab @ Home. Fab@Home - Make Anything. Onshoulders. PCB Milling. PCB Drill Press. Just a bunch of wires... Capacitor Discharge Microspot Welder / Cutter « PocketMagic. [lcamtuf.coredump.cx] Untitled. Build Your Own CNC Router, CNC Machine, or 3D Printer. Etching Revisited (October 24th edit) Auto Leveling Platform by atntias. DIY cable carrier. DIY Cable Carrier - Page 15. Why are plastic cable carriers so darn expensive? - Page 2.