How to build robotic stuff at home and more. Processing.org. Arduino robotics 2011. Www.mon-club-elec.fr/mes_docs/math/bras_5_servos/math_bras_5_servos.pdf. Control your motors with L293D and Arduino. Arduino Lesson 16. Stepper Motors.

Pappkamerad. Crash Space » Blog Archive » Take Apart Tuesday No. 6 – HP 1120C. So a bit of a rewind on Take Apart Tuesday.

This is the write up for February 9th. I was going to skip it and just go straight for hard drive we dismantled on the 16th, but a potentiometer actually smoked (sorry, no flames). It seemed like a requirement to share what that happened. So this week a bit on optical encoding, then some on stall torque and how it relates to component power ratings. Just for giggles I threw in some DC Motor code on the Arduino at the end. Encoding Speed and Location with a DC Motor So the original plan for for the HP DeskJet 1120C was to crack it open, swap out the ink cartridge for a pen and then control the stepper motors based on sensor data to create a custom output device that actually gives you an instant hard copy datalog like a seismograph or lie detector.

The tricky part is that once the 1120C was open it wasn’t actually a stepper motor controlling the horizontal location of the print head. Video on Retro-Tronics. The Media Computing Group : Back to Tools The original FabScan was developed by Francis Engelmann in his Bachelor's thesis (cost of materials: 150 Euros).

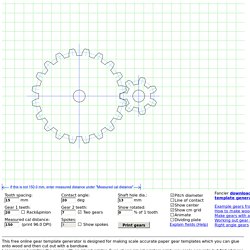

FabScan 100 further reduced material cost so that you could build one for just 100 Euros. FabScan Cube then featured an improved housing, as a result of a student group working on interactive assembly. FabScan Pi is the latest version. It includes a Raspberry Pi embedded computer for standalone operation and wireless scanning: Instead of controlling it from your laptop via USB, you can scan wirelessly from any web browser. Gear template generator. This free online gear template generator is designed for making scale accurate paper gear templates which you can glue onto wood and then cut out with a bandsaw.

I recommend printing the gears with an ink jet printer. Even cheap ink jet printers print very scale accurate but Not all laser printers are accurate. You can still access the old (pre 2015) Flash based gear geberator Getting the printout to scale correctly, avoiding cropping Different browsers print at different scales depending on browser type and printer configuration. Use an ink jet printer I recommend using an ink jet printer. Printing the gear templates To print the gear template, use the 'Print' button, instead of printing the web page from the browser.

The gear generator program that I created and sell doesn't need the scale calibration, and can paginate across many pages for larger gears. Analog servo principle - 3D printer list. How to Build a Robot Tutorials - Society of Robots. External Website Calculators:PCB Trace Width Calculator #1PCB Trace Width Calculator #2AVR Fuse Settings Calculator, with defaults for Axon and $50 Robot ATmega168.

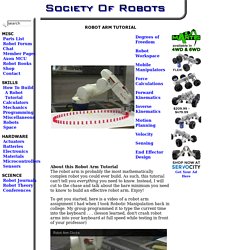

How to Build a Robot Tutorials - Society of Robots. About this Robot Arm Tutorial The robot arm is probably the most mathematically complex robot you could ever build.

As such, this tutorial can't tell you everything you need to know. Instead, I will cut to the chase and talk about the bare minimum you need to know to build an effective robot arm. Enjoy! To get you started, here is a video of a robot arm assignment I had when I took Robotic Manipulation back in college. My group programmed it to type the current time into the keyboard . . . You might be also interested in a robot arm I built that can shuffle, cut, and deal playing cards. Degrees of Freedom (DOF) The degrees of freedom, or DOF, is a very important term to understand. Denavit-Hartenberg (DH) Convention The Robot Arm Free Body Diagram (FBD) The Denavit-Hartenberg (DH) Convention is the accepted method of drawing robot arms in FBD's. 4 DOF Robot Arm, three are out of plane: CD drive scavenging for parts. Old CD drives are a decent source for parts to make things from.

Since the computer industry has encouraged manufacturing churn for so many decades, it is pretty easy to find at least a few surplus drives to dissect. Inside these dusty relics, you will be lucky to find DC motors, switches, gears, springs and more. The tools you will need are pretty easy to come by as well. From the parts you will find, you can make a number of interesting projects.

You can get drives from old computers, which always seem to be at the dump, on the sidewalk of some neighborhoods, out on the loading dock of the school, in basements and garages, etc. Teach your family to solder! Supplies: Old computer CD drives (older ones often have better parts) Plastic bags for storing parts (zippered half size sandwich bags are great) Small cardboard boxes for storing the larger metal and plastic partsBattery holder Tape Paper and pen Digital camera Paper clip.

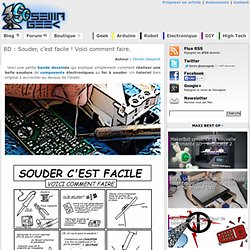

BD : Souder, c’est facile ! Voici comment faire. Voici une petite bande dessinée qui explique simplement comment réaliser une belle soudure de composants électroniques au fer à souder.

Un tutoriel bien original à accrocher au dessus de l’établi.