110304_Avalon_Fleming.pdf (application/pdf 对象) Griffin LanzaTech - 20 July 2011 MAS.pdf (application/pdf 对象) LanzaTech, Mitsui partner to scale gas fermentation technology. RileyFermentation.pdf (application/pdf 对象) BRI Synthesis Gas Fermentation Process Update. Bioengineering Resources, Inc.

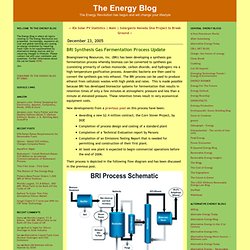

(BRI) has been developing a synthesis gas fermentation process whereby biomass can be converted to synthesis gas (consisting primarily of carbon monoxide, carbon dioxide, and hydrogen) via a high temperature gasification process. Anaerobic bacteria are then used to convert the synthesis gas into ethanol. Syngas fermentation. Syngas fermentation, also known as synthesis gas fermentation, is a microbial process.

In this process, a mixture of hydrogen, carbon monoxide, and carbon dioxide, known as syngas, is used as carbon and energy sources, and then converted into fuel and chemicals by microorganisms.[1] There are several microorganisms, which can produce fuels and chemicals by syngas utilization. These microorganisms are mostly known as acetogens including Clostridium ljungdahlii,[4] Clostridium autoethanogenum,[5] Eurobacterium limosum,[6] Clostridium carboxidivorans P7,[7] Peptostreptococcus products,[8] and Butyribacterium methylotrophicum.[9]Most use the Wood–Ljungdahl pathway. Syngas fermentation process has advantages over a chemical process since it takes places at lower temperature and pressure, has higher reaction specificity, tolerates higher amounts of sulfur compounds, and does not require a specific ratio of CO to H 2.[2] On the other hand, syngas fermentation has limitations such as:

LanzaTech. LanzaTech.

Spearheading New Ideas in Bio-commodity Technology. Our rapidly growing team of biologists, process design engineers, expanding patent portfolio and state-of-the-art lab facility are resulting in a list of capabilities unmatched in the industry. Gas Fermentation: our lab was specifically designed to allow quick and efficient investigation and research of every aspect of a commercial gas fermentation process.Synthetic Biology: we are now capable of defining and directing fuel and chemical production at the DNA-level. Our microbe has a WHO Category 1 safety rating (the same as Baker’s yeast).Microbiology: LanzaTech has one of the world’s largest collections of industrial fuel and chemical production microbes.