Why does my printer under-extrude? - IdeaTo3D. Under-extrusion: What is it?

When the printer isn’t able to extrude the requested amount of plastic, it means it is under-extruding. When it happens, the print will have some holes, missing layers or thin layers. The infill can also have these holes or lack of material, the layers aren’t well bonded together. After a while, the pressure in the head will increase and the feeder will do a skip back, this is a wanted an normal behavior, it prevents the filament from being grinded and also prevents damaging the feeder motor. 16 Common 3D Printing Problems and Solutions. Complete ABS Profile Settings - 3D Printing. Quality Settings: The layer height of your print is very dependent on the nozzle size of your printer as well as the quality of the print you would like.

We run our quality settings for ABS extremely similar to PLA (in case you had already read our PLA Settings guide). A printer with a .6mm nozzle can go up to .4mm layer heights, and a part with .1mm layer heights will take twice as long as one at .2mm, so these factors are important to consider. Our standard quality print settings are at a .25mm layer height. We then hone in the retraction settings for ABS. Makerjuice SF resin for Form 1. Home > Materials>DLP/SLA Resins>Makerjuice WAXCAST resin Makerjuice WAXCAST resin View larger Next New WaxCast is a high quality printing resin for direct investment casting applications such as jewelry, dental, and engineering models. 3 Items Delivery in 10 working days More info WaxCast was designed with casting in mind, and meticulously tested for that purpose by a handful of jewelers and engineers across the world.

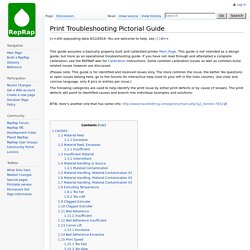

Less than 0.1% residual ash after burnoutNon-reactive with common investments such as Plasticast™Optimized for 25µm - 50µm layers, but can be adjusted by exposureLow degradation of PDMS vat coatingsQuick layer timesLow odor for use in commercial settingsResistant to most solvents, including alcohol and acetoneNo pigments to settle out Additionally, we’ve brought some new features to WaxCast not previously seen in affordable casting resins: Contains the very highest quality, natural waxes. Scheda Tecnica WaxCast (ENG) Download (1.71M) Reviews No customer comments for the moment. Print Troubleshooting Pictorial Guide. [>>still populating data 4/12/2014- You are welcome to help. see [1]<< This guide assumes a basically properly built and calibrated printer Main_Page.

This guide is not intended as a design guide, but more as an operational troubleshooting guide. If you have not read through and attempted a complete calibration, see the REPRAP wiki for Calibration instructions. Some common calibration issues as well as common build related issues however are discussed. (Please note: This guide is for identified and resolved issues only. The following categories are used to help identify the print issue by either print defects or by cause (if known). BTW, here's another site that has some info: Material Feed Excessive Insufficient Intermittent Material Handling or Source. Print Quality Troubleshooting Guide. 3D PrintShop - 3D Drucker, Filament und Zubehör. 11 Experts Share Their Top 3D Printing Beginner Tips. Let's be honest, 3D printing can be quite tricky.

Home 3D printing technology is still immature and 3D printing beginners who just bought their first machine are faced with a multitude of challenges when it comes to getting reliable and repeatable 3D print results. More... It is clear that a bit of expert guidance won't hurt! That's why we reached out to some of the top 3D printing experts and asked them the following question: What are your top 3 helpful tips for the new 3D printer owner? We asked the experts to share the knowledge and insights they have gained while spending hundreds of hours 3D printing and accumulating their fair share of failed prints. We have included a link back to each expert's website and social media profile in case you'd like to learn more about them and the work they are doing.

Grab a pen, take notes and implement the info. Just complete this form to download a handy, printable PDF of this post for you to keep forever! Jérémie Francois Blog: www.tridimake.com/ 3D Drucker Zubehör - was brauche ich? Mit der Anschaffung eines 3D Druckers ist es noch nicht getan.

Für die Vorbereitungen, die Einstellungen sowie für die Nachbearbeitung werden zusätzliche Dinge benötigt.