High Performance Resin Cases. La boutique 3D en ligne: Imprimante 3D, Filament 3D, Scanner 3D, Stylo 3D, Logiciel 3D. Le robot AxiDraw qui dessine et écrit au stylo s'améliore encore. 40 Affordable 3D Printers - On Sale under $500 - Buy Now. Cloud based KIRI:MOTO slicer makes 3D printing easy straight from your web browser. Feb 5, 2016 | By Andre As anyone that’s ever worked with 3D printers will know, there are steps that you need to follow before turning your model file into a 3D printed object.

The most important and arguably essential of these steps is what's called model slicing. This is a process that converts your 3D model into necessary layers and coordinates needed by your 3D printer before it can work its magic. In general, slicing software first needs to be downloaded to your computer before any slicing can occur. Well, serial entrepreneur Stewart Allen (a founding member of seven technology start-ups) has been working hard to bring these tools directly to your internet browser with his 3D model slicing gcode generator called KIRI:MOTO. After dragging and dropping your 3D model STL file onto the screen, you can rotate, multiply, and scale your file however you see fit. A final tool being developed under the GRID:SPACE family is what’s called META:MOTO.

3D printers. Les Chti’s de Dagoma lèvent 3 millions pour développer l’imprimante 3D «made in France» Le fabricant nordiste d'imprimantes 3D Dagoma vient de boucler un premier tour de table de 3 millions d'euros pour renforcer ses effectifs et ouvrir un centre près de Bordeaux.

Créateur d'imprimantes 3D Made in France - Dagoma.fr. What If da Vinci Had a 3D Printer? Take the Challenge! New Matter Store. TIKO. Trinus 3D Printer Laser Engraver on Kickstarter. Cheap 3D Printer Kits under 500$ Top 5 - 2016. RepRap. Ce chapitre explique l'origine de l'impression 3D.

Contrairement à ce que l'on entend communément, l'impression 3D ne naît pas d'une envie récente, mais fait suite à une volonté bien plus ancienne, dès les années 1970. L'origine du prototypage rapide Le prototypage rapide est une technique permettant de fabriquer des objets solides à partir d'un modèle numérique. Les premières machines de fabrication à commande numérique (CNC)* sont nées dans les années 50. Il s'agissait alors principalement de tours et de fraiseuses, mais qui étaient destinées à la production, non au prototypage.

The CowTech Cyclop - Very Affordable $99 Open Source 3D Scanner. Electron 3D Printer The 3D Power is ON. Qui sont les champions français de l’impression 3D? 3D Printed Micro Turbines to Bring Electricity to Urban Areas & Help the Energy Impoverished. Wind turbines are plentiful out west, lined up along the highways like futuristic, noble giants, doing their work gracefully, at the whim of what mother nature provides–often quite plentifully.

The positives are plentiful as well, reducing reliance on fossil fuels, offering jobs, boosting rural economies, and allowing for affordable, fixed price energy that does not have to be shipped or mined. Erected as incredibly tall monuments to alternative energy creation, the general thought has been that they generate more power higher up, where they are catching more wind–with the biggest blades possible, turning into the wind to catch the most energy. These are fairly complicated machines that can make a lot of electricity, and can be complicated to transport and set up, but even a small wind farm can generate enough electricity for an entire community, deeming the complexities worthy.

All three companies see these tiny turbines as allowing for a range of benefits. Max Micron – The First Affordable Dual Head 3D Printer With Auto Leveling and Laser Engraving Function. Poetry Infinity - IRA3D - Stampante 3D Professionale, Filamenti ed Accessori. Ultimaker 2 Family. Poetry Infinity: The New Superfast 3D Printer by IRA3D. FLUX ALL-IN-ONE 3D Printer.

CLIP Technology - Breakthrough technology centered on tunable photochemical process for layerless 3D printing. Thermistor. Thermistor Vitamin In most RepRaps, a thermistor senses the temperature of the Hot End.

Often a second thermistor senses the temperature of the Heated Bed. Thermistors are resistors that change of resistance with a change in temperature. Good qualities of thermistors are a predictable, accurately known resistance value at every temperature in its operating range. 3d Printer Guide - Smoothie Project. Probably the machine for which Smoothie is most used, due to Smoothie's roots in the RepRap project, 3D printers are fairly simple to Smoothiefy.

This is a step-by-step guide to connecting your board to the various components of the 3D printer, configuring everything, from the beginning to actual printing. This guide is a community effort, and this page is a Wiki. Please don't hesitate to edit it to fix mistakes and add information, any help is very welcome. Guide to Personal 3D Printers - Sculpteo Blog. There’s a 3D printer for everyone on the market today.

It doesn’t matter if you’re an individual designer looking to hack objects around the house, a large company looking to manufacture goods for a global market or anyone in between – there’s a printer for you. But it can be a bit confusing having to choose between all of the printers that are available and that’s why we’ve put together this guide to personal 3D printers (if you’re looking for a guide to professional printers that’s available here). We’ve arranged the information into the following categories: From there we give you the price of the printer, the printer bed size and a quick review of the printer qualities.

Most of the printers under $10,000 use either Fused Filament Fabrication (FFF) or Fused Deposition Modeling (FDM). More recently, stereolithography has emerged as another exciting type of at home 3D printing. Solidoodle Tips. Some people have had problems with their Solidoodles overheating, and having the hot ends fall apart despite using a temperature setting of 230C that is very high, but technically safe taken at face value.

I know that the temperature reading in Pronterface isn’t necessarily an exact real world temp. You need to find out what temperatures tend to work for your kind of machine and stick with them, ignoring recommended temps from other, different printers. Still, I wanted to find out what the difference is between temps reported in Pronterface, and real temperatures. I got a thermocouple, which is a temperature probe that attaches to a digital multimeter and taped it to the bare nozzle next to the thermistor.

The ideal method would have been running it down inside the hot end, but unfortunately that is not possible for one built to take 1.75mm filament. RepRap. Large Format Media. G-code. This page tries to describe the flavour of G-codes that the RepRap firmwares use and how they work.

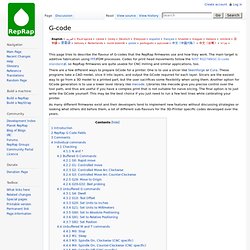

The main target is additive fabrication using FFF/FDM processes. Codes for print head movements follow the NIST RS274NGC G-code standard, so RepRap firmwares are quite usable for CNC milling and similar applications, too. There are a few different ways to prepare GCode for a printer. One is to use a slicer like Skeinforge or Cura. These programs take a CAD model, slice it into layers, and output the GCode required for each layer.

As many different firmwares exist and their developers tend to implement new features without discussing strategies or looking what others did before them, a lot of different sub-flavours for the 3D-Printer specific codes developed over the years. Introduction A typical piece of GCode as sent to a RepRap machine might look like this: The meaning of all those symbols and numbers (and more) is explained below. Here means: yes. Imprimer en ABS, le jus d'ABS. Jus d’ABS.

Bien le bonjour les curieux ! Suite à une « commande » de supports pour GoPro imprimés en 3D, j’ai du franchir le pas de l’impression ABS. Pourquoi ? L’ABS étant moins bio-dégradable que le PLA, ça m’a paru logique d’imprimer en ABS pour ce genre de pièce confrontée à un environnement extérieur souvent rude (soleil, montagne, mer/océan,…). J’ai donc du « repartir de zéro » au niveau connaissances, car l’impression en ABS est quand même bien différente que l’impression en PLA. Voici donc mes quelques conseils pour avoir des impressions réussies en ABS grâce notamment au jus d’ABS. Vue générale du langage G-codes de LinuxCNC. Les commandes modales sont arrangées par lots appelés groupes modaux, à tout moment, un seul membre d’un groupe modal peut être actif.

En général, un groupe modal contient des commandes pour lesquelles il est logiquement impossible que deux membres soient actifs simultanément, comme les unités en pouces et les unités en millimètres. Un centre d’usinage peut être dans plusieurs modes simultanément, si un seul mode pour chaque groupe est actif. Les groupes modaux sont visibles dans le tableau ci-dessous. PLA vs. ABS. Optimiser l’impression 3D. Avant de chercher à optimiser une impression 3D, il faut d’abord identifier le rôle de la pièce à imprimer. Est-ce un objet destiné à la vente, un prototype, ou encore un premier test fonctionnel ?

Actualités. Dans le monde de l’impression 3D « industriel », de nombreux matériaux ont été développés afin de diversifier l’offres et les applications possibles de cette technologie. En dehors de l’industrie pure, il y a les imprimeurs 3D en ligne tel que Shapeways ou Sculpteo, dont la gamme de matériaux disponibles, déjà bien fournie offres des possibilités de rendu de plus en plus variés( différents aspects, transparence, solidité, etc..). Chez les particuliers, pour l’instant, il n’y a guère que des imprimantes à extrusion de filament de plastique que l’on rencontre, et force est de constater que la gamme des matériaux disponibles et nettement plus limitée… Pour autant, il y quand même quelques possibilités : 1 ) Les matériaux « Historiques » 2 ) What else ?

Deltaprintr - A simple, affordable 3D Printer! by Deltaprintr. We engineered the Deltaprintr to be simple, efficient, and affordable. We want as many people as possible to be able to get their hands on this exciting new technology without having to sacrifice quality or user-friendliness. SIMPLE - Using a 3D Printer shouldn't be a hassle. We designed our printer so that it requires minimal set-up, and so that there's effectively no long-term maintenance. We'll be shipping every printer with a construction manual (pictures!)

To get you up and running in no time. EFFICIENT - The polar coordinate system allows for faster movements (than those of traditional Cartesians printers) while achieving a 100 micron resolution. FABtotum Personal Fabricator. FABtotum : une imprimante 3D + scanner + fraiseuse, tout-en-un. Imprimante 3D. High Resolution Desktop 3D Printer. 3D printing applications. Moteur d'impression 3D Sculpteo dans le Cloud.