Master Basic Welding Skills: A Step-By-Step Guide. A thing of beauty is a joy forever.

And around our Saturday Mechanic shop, beauty often takes the form of a perfectly laid welding bead--one that looks like a tall stack of dimes laid on its side. Okay, welding has some practical aspects, too. Your world, as a tinkerer and fabricator, fundamentally changes when you can permanently fasten two pieces of steel together in seconds. Sure, it takes years of experience to perfect the craft, and an investment in welding equipment. But don't let the cost intimidate you. The first project most new welders tackle is predictable--you need a shop cart to hold that new welder and warehouse the accessories. So what's the best way to learn welding skills? Make An AC Arc Welder Using An Old Microwave, Part 1. In a previous article, I demonstrated an Arc Welder made using parts from old microwave ovens.

Here is part 1 of 2 on how that arc welding machine was made, and how you could make one too! This is the first of two parts on building it, focusing on the modification of the transformers. WARNING: Stick welding, and/or the modification of a Microwave Oven Transformer (M.O.T), can be very dangerous and presents risks of UV radiation, shock hazards, burns, fires, fumes and a multitude of other risks. This project should not be attempted without a thorough understanding of electricity, adult supervision and adequate training. Misuse, or careless use, of tools or projects may result in serious injury and/or death.

In a previous project, I melted the lead wires on my first metal melter. The arc welder made sparks fly, but in the end, it wasn't enough power to make the metal stick, and the pieces of work would break apart with very little effort. The modified transformer is complete! Welding Wrought Iron. Home - The Artful Bodger's Home Foundry. Backyard Metalcasting.com. DIY Solar Foundry - Temps Of 3800 degrees F. Of all the ways to heat metal to melting points in order to work with it, using the sun's heat is not usually listed among them.

But Green Power Science does just that with this DIY solar foundry. Metal-working, in the backyard, without an open flame. Crazy! © Green Power Science via Instructables But also still fairly dangerous. That's hot!!! Watch some of the metal working that is possible with this solar concentrator: This is an entry in the Instructables Green Design Contest. Think “green” and submit an eco-friendly Instructable that uses sustainable materials or is energy efficient by design... Inexpensive Soft Metal Bending Tool. This project may not seem extremely exciting but it is very useful and satisfying to create other parts with once it is finished. It IS exciting, get EXCITED! If you are a true Maker, you are already teeming with excitement over the fact that you are reading another instructable and expanding your mind's quiver.

Recently, I needed 90 degree bends in aluminum stock to create brackets for a project I have going. I grabbed $25, ran to Home Depot and after a few hours created my own metal bending tool. Quick, dirty, simple and cheap. A Few Quick Notes: The symbol " denotes inches. Metal Bender. No matter what your hobby, sometimes you need to bend some light weight metal into nice, circular shapes.

This instructable will show you how to make a metal roller out of old printer rollers and some angle iron. So far, I have used this bender to make circles out of 1x1/16 aluminum for some of my hobby robots, to bend some 1x1/8 inch aluminum into a perfect circle for a US First Robotics high school team I mentor (Go Team 1631), and to bend two 5 inch wide 1/8 inch steel sheets 9 feet long for a fire pit I am making (but that’s another instructable).

This instructable will have you cutting metal and braising. Don’t forget all the safety rules involved with each of these activities. If you are new to any of the tasks below, I recommend looking up safety tips on the internet before trying something new. Guide To Making Holes In Sheet Metal - How To Work With Sheet Metal. Free Metal & Wood Projects. The Free projects category is dedicated to people who find pleasure in making various useful things from wood or metal.

Every single man that has done something with his own hands knows what a great satisfaction it is to look at a finished assembly. That satisfaction comes out from the quality time he spent, applying of knowledge and experience, overcoming many challenges and obstacles that emerge during the manufacture and also from the fact that he made some useful thing with his own hands and does not have to buy it. People are much more attached to the things that they made by themselves than to the industrial products, even if their own handwork is usually simpler. And because of that pleasure, here we are offering you the plans for manufacturing various items, regardless whether they are rarity in the market or common everyday objects – from a completely simple to quite complex ones.

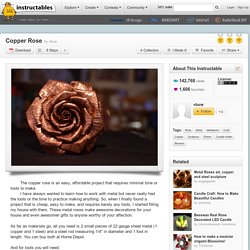

The individual manufacture of various useful or decorative items is not just a hobby. Copper Rose. The copper rose is an easy, affordable project that requires minimal time or tools to make.

I have always wanted to learn how to work with metal but never really had the tools or the time to practice making anything.