Project:Nanode - London Hackspace. Nanode 5 We have been nominated for an award Nanode has been nominated for an award as the Best Internet of Things Open Source Project 2011.

You can support Nanode with your vote here. OpenEnergyMonitor.

An MIT Center for Bits and Atoms Project. Cnc. Contraptor. Dank. Grbl is a free, open source, high performance CNC milling controller written in optimized C that will run on a straight Arduino.

Get the code at Github | Follow Grbl on Twitter MIT Center for Bits and Atoms designed a beautifyl snap fit CNC machine controlled by Grbl. Nortd Labs runs their open source laser cutters with a Grbl-based firmware Who shoud use Grbl Makers who do milling and need a nice, simple controller for their system (and who can handle the lack of a user friendly, graphical client) People who loathe to clutter their space with legacy PC-towers just for the parallel-port Tinkerers who need a controller written in tidy, modular C as a basis for their project. Nice features Grbl is ready for light duty production. The G-code interpreter impements a subset of the rs274/ngc standard and is tested with the output of a number of CAM-tools with no issues.

Acceleration management Limitations by design At this time we have no nice desktop client for Grbl. Coming attractions. GRBLshield CNC Milling Machine Conversion. Adafruit Industries. Welcome. Mantis 9.1 CNC Mill - Make Your Bot! The Mantis 9.1 design is a radical departure from version 8 and earlier.

Most notably, the part count has been almost halved! The current design has 13 parts, all of which can be made with a handsaw and a drill press. Also, I've traded away my alignment free exactly-constrained design for extra stiffness. Several unsuccessful attempts to eradicate the last of the slop in the Z axis on version 8 lead me back to the world of over-constrained parallel rods. My previous attempts at an over-constrained design (versions 1-5) all failed because I was unable to make the rods sufficiently parallel to avoid jamming. The solution to this problem came to me one day in the shower— stack the two wooden endplates, and then drill the rod holes through both pieces at the same time.

Once we have a precise set of holes, it's easy to slip two sliding brass bushings on each of the rods and press the rods into the endplates. Video Build Instructions David's Original Plans Australian Plans Parts Suppliers Back. Blog - Sam Redfield on Pico-hydro at La Florida. Wiki. RepRap is humanity's first general-purpose self-replicating manufacturing machine.

RepRap takes the form of a free desktop 3D printer capable of printing plastic objects. Since many parts of RepRap are made from plastic and RepRap prints those parts, RepRap self-replicates by making a kit of itself - a kit that anyone can assemble given time and materials. It also means that - if you've got a RepRap - you can print lots of useful stuff, and you can print another RepRap for a friend... RepRap is about making self-replicating machines, and making them freely available for the benefit of everyone. We are using 3D printing to do this, but if you have other technologies that can copy themselves and that can be made freely available to all, then this is the place for you too.

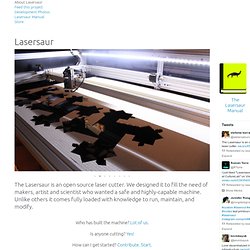

Reprap.org is a community project, which means you are welcome to edit most pages on this site, or better yet, create new pages of your own. RepRap was voted the most significant 3D-printed object in 2017. Thingiverse - Digital Designs for Physical Objects. Buildlog.net - CNC Laser Buildlogs. Simen/grbl - GitHub. Lasersaur. Lasersaur The Lasersaur is an open source laser cutter.

We designed it to fill the need of makers, artist and scientist who wanted a safe and highly-capable machine. Unlike others it comes fully loaded with knowledge to run, maintain, and modify. Since its conception, Nortd Labs and the Lasersaur community has generated knowledge to develop a comprehensive system.

We have specifically focused on laser cutting, software, and making the building process repeatable. How can you Contribute? Unlike software, hardware RD is costly even when living off of Ramen. Short on cash? $32 Beta Access: Support the project and get full access to design documents, community (mailing list), and software before the project goes fully open source. $(any) Project Support: Simply want to support the project?

We Accept Bitcoin! Credits Mad props to reprap.org, www.cnczone.com, arduino.cc, grbl, buildlog.org, and their giants' shoulders. CNCzone.com-Machinist Community Forums - Welcome Page. Make your own open source Android smartphone - eco-diy.