The #3dprinting Daily. Eleven 3D Printing Predictions For the Year 2011. This is a guest post by Joris Peels, the Community Manager of i.materialise, a 3D printing service for designers, inventors and consumers.

They are part of Materialise, a company with over 20 years experience in 3D printing and the market leader in 3D printing services and software. Making predictions is a sure fire path towards getting ridiculed. But, I’ll be brave and go right ahead and make 11 predictions for 3D printing in 2011. Makerbot will sell more than 10,000 3D printers in 2011. To put that in perspective, there are approximately 30,000 3D printers in the world today. Bre Pettis will appear on the cover of Bloomberg Businessweek magazine in 2011.Bre Pettis is the congenial Maker in Chief of Makerbot. Manufacturers Turn to 3-D Printing. Hobbyists may have provided the first demand for 3-D printing, but while DIY enthusiasts were creating online communities to make their own action figures and knickknacks out of plastic, industrial manufacturers were discovering how new materials and techniques in 3-D printing could change the way they make commercial products.

A 3-D printer deposits a string of hot plastic, lets it cool, and moves on to the next plane to build a three-dimensional object slice by slice. Using the same principles of layering, additive manufacturing can build objects out of metals, plastics, and ceramics in geometric shapes that are impossible to achieve with other manufacturing techniques. Because the design is digital, businesses can order the resulting products from any available 3-D printer. This May, General Electric announced that it would intensify its focus on additive manufacturing to develop a variety of products, from aircraft engine components to parts for ultrasound machines. 3D Printing: It’s Real, And Real Work » Danny Thorpe.

Kudos to ZCorp for their recent new video reaching a lot of people (3.9 million views on YouTube as of this writing) who clearly had never heard of 3d printing before.

However, all these 3D noobs blathering on about “wow! 3D printing is brand new!” And “star trek replicators are real!” Is really becoming irritating. » 3D Printing Sucks or the State of Things Open Buddha. Alice...my makerbot Look around and you'll see more and more articles in the mainstream press about 3D printing and printers.

Makerbot Industries has built a business (and gotten investment) on kits for 3D printing over the last few years and there are actually a number of competitors now for them in the hobbyist market. Reprap hobbyist printers have existed for years before that as a DIY open source movement (with all that entails) as well. The world's first printed plane - tech - 27 July 2011. Read full article Continue reading page |1|2.

The world's first printed plane - tech - 27 July 2011. Read full article.

» 3D Printing Sucks or the State of Things Open Buddha. Eleven 3D Printing Predictions For the Year 2011. 3D Printing: It’s Real, And Real Work » Danny Thorpe. Manufacturers Turn to 3-D Printing. Manufacturing, 3D Printing and What China Knows About the Emerging American Century - Mark P. Mills - Energy Intelligence. 3D printing and human skill. Posted by Jon Udell under Uncategorized[22] Comments This National Geographic video about 3D printing exemplifies the worst kind of gee-whiz reporting.

Just scan a crescent wrench, print it, and bingo, you’ve copied a real tool with moving parts! Not. A commenter notes differences between the copy and the original and concludes: If the real wrench was simply scanned, this would not have happened. The input method is, of course, 3D CAD. How 3D Printing Will Make U.S. Self-Sufficient. Design And The New Industrial Revolution If you hadn’t heard, there’s a new industrial revolution sweeping the world.

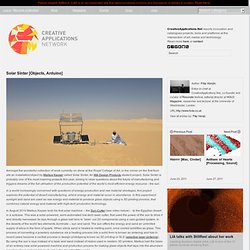

This revolution, say the champions of this new kind of making, is the result of three factors that together change the nature and economics of manufacturing. The first is free software for designing complex 3D objects; the best known example being Google Sketchup. The second is 3D printing in which computerised machines turn virtual designs into physical models that you can prod, fondle and squeeze. Finally, there is the precipitous drop in the cost of 3D printers and other rapid prototyping techniques. This suddenly makes it practical and profitable to make-on-demand instead of mass producing products. How 3D printing is saving this jewelry design business.

It may sound like something from a sci-fi movie—a machine that prints out actual models of designs, rather than two-dimensional renderings on paper—but three-dimensional printing is not only real, it has established a beachhead with businesses of all kinds in recent years.

As prices on the machines fall, small business owners, particularly those such as industrial or architectural designers using computer aided design, or CAD, for product development, are accessing the technology. Some are buying their own machines; others outsource their designs to another business that provides this service. The technology works hand in hand with 3D CAD models by building up microscopic layers of plastic resin and hardening them with ultraviolet light similar to what dentists use for porcelain fillings. The print beds are typically about 20 inches square and can print up to 10 inches high; they can also print out multiple designs at once.

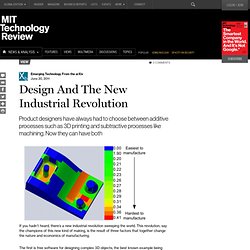

'Solar Sinter' by Markus Kayser is a solar powered 3D printer that uses sand as source material #3dprinting #environment #energy #rca. Amongst the wonderful collection of work currently on show at the Royal College of Art, in the corner on the first floor sits an installation/object by Markus Kayser called Solar Sinter.

An MA Design Products student project, Solar Sinter is probably one of the most inspiring projects this year, aiming to raise questions about the future of manufacturing and triggers dreams of the full utilisation of the production potential of the world’s most efficient energy resource - the sun. In a world increasingly concerned with questions of energy production and raw material shortages, this project explores the potential of desert manufacturing, where energy and material occur in abundance. What is 3D printing? A beginner’s guide to the desktop factory - Yahoo! News. Deep in a sub-basement of the GM world headquarters, dozens of high-tech machines emit a soft whirring sound. In a sandy liquid, as an arm passes quickly overhead while a model slowly emerges. It’s the side-mirror of a new concept vehicle with a place to insert the mirror and bolt the part into place. This rapid-prototyping room runs all year long, every day, seven days a week.

The machines never quit. Designers make dozens of “first run” models that are fitted with other parts. While rapid-prototyping is common with large automotive firms, similar techniques are used by hobbyists and professional designers at home. Full Print3d. Printing Objects. How 3D Printing Will Make U.S. Self-Sufficient. 3D printing glass in the desert. If you were stuck in the desert & only had one provision to choose from, what would it be? Well if your name is Markus Kayser you’d likely take your solar sintering 3D printer of course! The abundance of sand and sunlight in this environment provides both raw materials and energy. Allowing any failed mutineer or downed pilot to make nearly any provisions they could ever dream of!

“By using the sun’s rays instead of a laser and sand instead of resins, I had the basis of an entirely new solar-powered machine and production process for making glass objects that taps into the abundant supplies of sun and sand to be found in the deserts of the world.” – Kayser Video and further images after the jump… This printing method employs no bonding agents nor synthetic support material – only using the raw materials readily available.

Kayser concisely sums up his project: Without a doubt this must be the most sustainable additive manufacturing process ever put into production. Emergent City / Joseph A. Sarafian. “Emergent City” is Joseph A. Sarafian’s 5th year Thesis project at the University of Southern California in Los Angeles. “By the turn of the Twenty-Second century, a new epoch in global survival had emerged. The human race was no longer concerned with sustainability as a trend, because it could no longer deny the fact that the world was in fact dying. De tipping point voor 3D printing is daar. Binnenkort wordt 3D printing gemeengoed. Daarmee ontstaat een wereld waarin niet alles meer in massa wordt geproduceerd. Iedereen kan zich ontwerper noemen en eigen producten maken in steen, metaal, plastic of glas; het maakt niet uit.

Dit zal grote gevolgen hebben voor de e-commercewereld. Webshops zijn bij uitstek in staat om consumenten de mogelijkheid te bieden zelf producten te maken en te verkopen. The Pirate's Dilemma. Here you can download an electronic copy of the book. The price is entirely up to you. To download, simply click on the link above or the book cover pictured on the left. You’ll be taken to a checkout page where you can set the price anywhere from $0.00 upwards. You’ll need to enter your email address, but I respect your online privacy and promise never to spam you. Why would an author give away a book for free? Human Cloning in Japan. Enterprise Resilience Management Blog: 3D Printing and the Supply Chain. The editorial staff at Supply Chain Digest asks an interesting question: "How Soon will 'Printed' Parts Revolutionize Supply Chains - and the World? " [22 February 2011] I first posted a blog that mentioned 3D printers back in November 2006.

I discussed the subject at more length the next year in a post entitled Where is My Replicator? At that time, 3D printers were still pretty much an expensive novelty item. Staffers at Supply Chain Digest write, "The world of digitally 'printed' components and finished goods is (somewhat under the radar screen) achieving enormous technical improvements and has moved rapidly from vision to reality, with enormous potential implications for supply chains and business. " THE NEXT TRILLION DOLLAR INDUSTRY: 3D Printing. 3-D Printing Is Spurring a Manufacturing Revolution. Fab lab-3D printing. The Homebrew Industrial Revolution. 3D Printing. Feed a device with blueprints for a solid object of your choosing, then let the machine build it for you from plastic or other simple materials [1] Video illustration at "3D Printing” is an umbrella term that covers four distinct manufacturing technologies.

All are “Additive Fabrication” processes that create objects by adding material in thin layers until a product is completed. Each technology addresses the challenge differently with accompanying benefits and drawbacks. 3D printing: The printed world.

No Endorsement. My 2009 novel Makers concerned itself, partly, with the upheaval that might attend cheap, ubiquitous 3D ‘‘printing.’’ Makers (9780765312792): Cory Doctorow. 3D printing and human skill. REPLICATOR — Putting the "Custom" Back In Customer. Gifs have become a fixture of the web, transformed Buzzfeed into a major media entity, and brought countless millions of hours of joy to bored office drones the world over.

There’s a gif search engine and a service that will turn these little moments of web zen into IRL animated pictures. So why aren’t these miniature animations used more widely for practical purposes? The Future of 3D Printing. A printed trefoil knot, printed on a CandyFab printer at nearly 20 dpi Source: Evil Mad Scientist Laboratories A vase printed with the Z Corp Spectrum Z510 printer. Get_file (application/pdf Object) It Will Be Awesome if They Don't Screw it Up: 3D Printing... 3D printing provides a vision of manufacturing's future (w/ video)