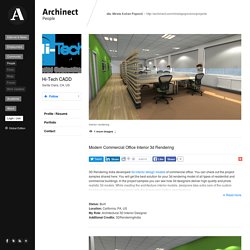

Residential House Model: 3D Architecture. 3D Interior Rendering of Commercial office. Anchor 3D Rendering India developed 3d interior design models of commercial office.

You can check out the project samples shared here. You will get the best solution for your 3d rendering model of all types of residential and commercial buildings. In the project samples you can see how 3d designers deliver high quality and photo realistic 3d models. While creating the architecture interior models, designers take extra care of the custom furniture & fixtures required along with the texture and lighting specifications. See more projects at Status: Built Location: California, PA, US My Role: Architectural 3D Interior Designer Additional Credits: 3DRenderingIndia 3D Interior rendering. Getting Valuable Answers through CFD Simulations. Most often, computational fluid dynamics (CFD) is seen as a replacement tool against experimental investigations.

Engineers try to calibrate the results obtained through CFD to match exactly with the real world conditions; however, the reality is that CFD results always differ. Even if you try to keep on iterating the results and develop smaller meshes, a slight variation in the results is bound to occur when compared to real world conditions. This clearly indicates that why experimental results still matter while designing products.

Selecting the Right CAD Model for Reverse Engineering. Posted by: Gaurang Trivedi | Posted on: April 29th, 2015 Reverse engineering is seen as one of the most profitable methods for manufacturers to develop new products from existing ones, restore design data of obsolete parts and study competitor products.

However, reverse engineering makes use of CAD tools to covert the design information obtained through scanning or CMM’s. Selecting the right CAD model is important while performing RE to ensure that the design information is accurately converted and there is no data loss while transition. The CAD model depends mainly on the type of requirement and the object being considered to reverse engineer.

Here are some of the most common CAD model formats that are developed for specific applications. Polygonal Modeling (STL) CFD Analysis for Engine Design: Fuelling innovation. CFD- computational fluid dynamics is a tool that can furnish designers with detailed and useful information, which can be fed back into the design to develop a well engineered product.

It is widely used across the automotive industry for automobile design and development – Specifically for automobile engine design. In CFD analysis, a mesh that represents an engine in the form of a 3D geometry – including all the sub models for fuel injection, turbulence, chemistry and combustion, is used to solve the fundamental equations that describe a fluid flow. Using CFD capabilities, engineers can visualize and analyze the moving geometry and its effect on fluid flows and the complex interactions that occur within an engine.

CFD Analysis for Engine Design CFD analysis for an automobile engine design can be bifurcated into various levels each being more complex than the previous, namely – port flow analysis, cold flow analysis, IC combustion simulation, and full cycle simulation. Measuring Lift & Drag Forces for a Flow Over Formula1 Car’s Rear Wing. Structural and Vibration Analysis of Bracket Design. The Need to Revolutionize CFD Capabilities for Future Aircraft. Computational fluid dynamics (CFD) has remained a vital tool for aircraft design assessment ever since its inception.

Its use has already brought a paradigm shift in the aircraft design process. Jan 6, 2015 -- However, since past decade, the advancements in this technology has reached a stagnation point as RANS methods have become a high-fidelity method of choice as it permits the use of large meshes, complex geometries and more number of runs. The Case for CFD: Uncovering the Science Behind Internal Combustion Engine Phenomenon.

Predicting Fatigue in Pressure Vessels Using Finite Element Analysis. The purpose of pressure vessels is to store gases and liquids at pressure range different from ambient conditions.

Improving Frictional Grip between Pipe and Bracket for Engine Oil Line. Why Verification and Validation Should Be A Part of FEA Studies? Finite element analysis is a numerical approach to evaluate solid mechanics problems.

Today, most engineers utilize this approach as a means to assess the product design performance. FEA however requires creating a mathematical model from the CAD model by defining the geometry, loads and constraints along with the type of analysis required to be performed such as structural or thermal. Eliminating Hot Spots Using Computer Aided Engineering. Most engineering products involve their application under extreme thermal environments.

Examples could range from electronic components such as microprocessors to mechanical devices such as turbines, compressors and engines. All these devices are exposed to high temperatures, causing possible damage due to thermal stresses and subsequent deformation. One of the prime concerns for design engineers in such cases is to avoid building up of thermal concentrated regions often referred to as hot-spots. Moreover, with increasing requirement from the market to build compact products, the situation is even more challenging to engineers in designing products that remain thermally uniform during their applications. A hot spot can be imagined in a thermally sensitive product such as a heat exchanger utilized in industrial applications. CFD: An Intuitive Tool for Efficient Thermal Management of Data Centers.

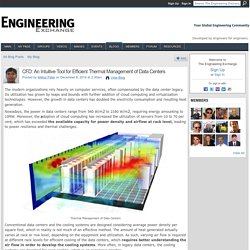

The modern organizations rely heavily on computer services, often compensated by the data center legacy.

Its utilization has grown by leaps and bounds with further addition of cloud computing and virtualization technologies. However, the growth in data centers has doubled the electricity consumption and resulting heat generation. Nowadays, the power in data centers range from 540 W/m2 to 2160 W/m2, requiring energy amounting to 10MW. Visualizing Fluid Flow Inside the Modified Inlet Duct. Design Optimization of Cooling Component through CFD Analysis. Evaluating the Reliability of Underrun Protection System in Heavy Vehicles Using FEA. Underrun protection systems, often known as underride guards, are utilized in trucks and buses to prevent intrusion of small passenger cars during the event of collision.

Research figures reveal that trucks with a gross weight of more than 3.5 tonnes are involved in 20% of the road accidents; from which, 60% are car to truck accidents. It is obvious that the injuries are far more fatal for small vehicles during such collisions. Most common accidents however are front and rear collisions, resulting into fatal injuries for car passengers. Evaluate the HVAC Capability of the Proposed Airport Design. CAE Driven Product Development: A Competitive Tool for SMEs. Computer Aided Engineering techniques have been in the engineering domain from past several decades, and has been tremendously improvised to eliminate the use of experimental validations. Research shows that all the best in class manufacturers utilize simulation in the design phase to develop better, faster and cheaper products.

The reason for such an immense inclination of manufacturers towards adopting simulation tools in the design process is the ability to bring products in the market as much fast as possible. However, the increasing competition in placing the products in the market faster poses challenging situation for small and medium scale manufacturers in delivering their products at the right time. This necessitates for SMEs to realize the importance of CAE tools and incorporate them in the product development process. Considering an example of automobile parts manufacturers, the Tier-2, 3 and 4 suppliers face such competitive challenge at the most. Guest posted by Hi-Tech CAE. CFD Helps to Predict the Flow Behaviour inside Building HVAC Application. Structural Assessment of Tower Subjected to Wind and Wave Loads. Understanding the Concept of Topology Optimization to Develop Lightweight Products. Checklist to Ensure Validity of Your Finite Element Structural Analysis.

Why Physical Testing of Industrial Equipment Will Never Be Sufficient. Industrial equipment manufacturers are struggling to differentiate themselves in today’s tightly competitive market. To remain ahead, it is important for these manufacturers to adopt innovative strategies and right technology to meet the growing customer demands on time. This is where physical tests lag behind; evaluating equipment through physical testing might be considered as a gold standard but is often time consuming and costly. According to a report from Tech-Clarity, 38% of manufacturers find meeting customer delivery schedules as one the most critical challenge in today’s market conditions. It clearly signals the importance of simulation tools in speeding up the validation process.

Alternative Design Rules for Pressure Vessels & Why You Need Them. The Design by Analysis (DBA) was introduced later in Division 2 within the ASME BPVC Codes to allow better design, which optimizes manufacturing process and decreases production costs. The Division 2 consists of more complex but accurate formulas and allows the design to obtain higher stress values, providing a room to reduce the material usage. When comparing this alternative approach with the Design by Formula or the Division 1, there are lot of improvements in terms of optimizing the design, rather than relying on empirical relation that give out conservative design.

However, what makes the use of Div. 2 more profound is the ability to analyze complex pressure vessel designs. If you are simply creating a tank without any extremely angled nozzles or sharp transitions, design by formula works best. But, with complicated geometries and loading conditions, you will need Div. 2 guidelines and perform the analysis using any industry standard program.

Leading the Industrial Equipment Manufacturing Market through Best Design Practices. Applying Fluid Structure Interaction to Automotive Aerodynamics. Aerodynamic studies on vehicles have become a mandate for manufacturers. How CFD Simulation Is Helping Preserve a Precious Resource: Our Food. The Continuing Education Center offers engineers an entirely new way to get the education they need to formulate next-generation solutions. 8 Courses Over Six Months: July - December Building Raspberry Pi Controllers with Python. Using CFD to Obtain Improved Thermal Management of Electronic Component Cooling. Electronic components such as PCBs, microprocessors, batteries, etc. are required to operate at temperature within their allowable limits. This requires dissipating excess heat generated due to potential difference or Joule heating to prevent premature failure. A usual approach to provide cooling is by means of natural or forced convection using fans and coolants for air and liquid cooling respectively.

However, as market requirements continuously shift towards miniaturization of these devices, thermal management of electronic components is a challenging task. On account of these challenges, several researches has already been carried out on utilizing high conductivity materials, modification in the design of heat sinks and application of extended surfaces (fins) wherever required.