Un rapprochement fructueux des systèmes industriels et des systèmes d’information. #ConvergenceIT-OT – Les entreprises mènent actuellement de grands chantiers pour s’approprier les possibilités grandissantes d’optimisation et de valorisation apportées par le traitement des données.

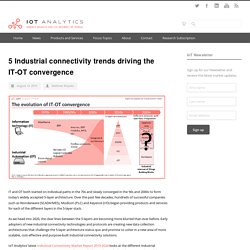

C’est dans ce cadre que le groupe de travail 2018-2019 du Cigref “Convergence IT-OT” piloté par Gilles Lévêque, DSI du Groupe ADP, publie le fruit de sa réflexion dans un rapport “Convergence IT-OT : Un rapprochement fructueux des systèmes industriels et des systèmes d’information”. Ces chantiers menés concernent notamment les systèmes industriels où sont produites les données opérationnelles de l’entreprise. 5 Industrial Connectivity Trends Driving the IT-OT Convergence. IT and OT both started on individual paths in the 70s and slowly converged in the 90s and 2000s to form today’s widely accepted 5-layer architecture.

Over the past few decades, hundreds of successful companies such as Wonderware (SCADA/MES), Modicon (PLC) and Keyence (I/O) began providing products and services for each of the different layers in the 5-layer stack. As we head into 2020, the clear lines between the 5-layers are becoming more blurred than ever before. Early adopters of new industrial connectivity technologies and protocols are creating new data collection architectures that challenge the 5-layer architecture status quo and promise to usher in a new area of more scalable, cost-effective and purpose-built industrial connectivity solutions.

IoT Analytics’ latest Industrial Connectivity Market Report 2019-2024 looks at the different industrial connectivity architectures, components and protocols that are being deployed to create industrial data collection solutions. 3. 4. 5.

The Manufacturer’s Complete Guide to IoT — Drive Efficiency with Embedded Intelligence. Manufacturers struggle to stay competitive in times when customer expectations are through the roof, the global supply chain is getting increasingly complex, and customization is a necessity.

Now, manufacturers explore more innovative ways of solidifying their foundation in the marketplace. La filière bois a rendez-vous avec l’industrie 4.0. L’industrie 4.0, la prochaine révolution industrielle pour la filière bois ?

Elle renferme des promesses de machines connectées qui « communiquent » entre elles, de productivité et de flexibilité accrues, de meilleurs rendements qui limitent la perte de matière et d’optimisation des machines grâce à la maintenance prédictive. Les scieries comme les spécialistes de la construction bois ont rendez-vous avec l’industrie 4.0. Cela vaut aussi pour les papetiers ; en témoigne Paul-Antoine Lacour, délégué général de la fédération Copacel : « Nous avons l’habitude de l’automatisation et de la collecte des données. Nous pourrons aller plus loin, dès que nous aurons identifié les bonnes technologies pour gagner des points de marge. » L’industrie 4.0, automatisation toute C’est une lame de fond appelée à toucher tous les secteurs de production.

Des machines pour le bois de plus en plus connectées. IoT Resources: Events, Research & Examples. Digital industrial transformation in the age of Industry 4.0. In a shifting market landscape with constant disruption, leveraging automation to optimize production is a challenge.

Introducing a series of articles to help guide leaders through digital transformation in an Industry 4.0 age. Introduction Are you prepared to succeed in the Fourth Industrial Revolution? How to Start Your Digital Transformation with Condition Monitoring. Flexible evolution possibilities and expandability make IoT-enabled condition monitoring a perfect starting point for digital manufacturing.

Its key role is being a source of real-time data about the health of industrial machinery and the environment in which it operates. Leveraging this data, IoT-driven condition monitoring allows monitoring the current state of industrial machinery and identifying the combinations of equipment’s health, operational, and ambient parameters that can lead to potential equipment failures or cause product quality deterioration. However, the solution’s capabilities are even wider than that. Digital darkness in manufacturing floor leaves plant management blind. December 9, 2016 | Written by: Binny Samuel Categorized: Manufacturing Share this post: Most manufacturing plants are digitally dark.

They collect limited set of data from plant floors, essentially only that which pertains to key metrics or key processes. But for those, there are hardly any digital visibility that drive decision making or predictive insights that illuminates production risks. Plant managers start the day with little visibility on what is going to happen during the day; neither have idea on what the day’s productivity will be, nor have insight on potential constrains they will meet in the course of the day. The maintenance department is flooded with corrective and emergency maintenance work orders even as they religiously keep recommended preventative maintenance schedules because they lack the ability to foresee the condition of machines and adopt the maintenance approach accordingly. Today manufacturers have alternatives for managing the plant better. IoT in Manufacturing: The Ultimate Guide. Stronger demand for customization, increasing customer expectations, the complexity of the global supply chain – these and many other challenges encourage manufacturers to find new, more innovative ways to remain competitive.

In an attempt to gain productivity improvements and uncover new ways of enhancing manufacturing and supply chain operations, businesses resort to digital transformation. Machine utilization monitoring across distributed factories with IIoT. Imagine an enterprise that runs several geographically dispersed factories.

The company has to monitor utilization of hundreds of various machines and seeks ways to optimize the process since traditional report-based methods don’t seem to work well. Despite the thorough observations of process operators, line supervisors, shop managers and factory managers, the data gathered with traditional methods is not always reliable. Etude Agrion IOT 2. The Industrial Internet of Things (IIoT): the business guide to Industrial IoT. A complete guide about IIoT (the Industrial Internet of Things or Industrial IoT) with definitions, market evolutions, use cases, standardization efforts, challenges and strategic approaches across the globe.

The Industrial Internet of Things originally described the IoT (Internet of Things) as it is used across several industries such as manufacturing, logistics, oil and gas, transportation, energy/utilities, mining and metals, aviation and other industrial sectors and in use cases which are typical to these industries. The industrial IoT market is estimated to reach $123.89 Billion by 2021.

Accelerate Your Transformation with Desoutter 4.0 - Desoutter Industrial Tools. A technical primer on the Internet of Things. The Internet of Things connects people, places, and products and, in so doing, it offers opportunities of value creation and capture for a full panoply of stakeholders. Organizations, however, should be careful in focusing on IoT initiatives that solve real business problems and create real business value―not just connecting stuff for the sake of connecting stuff.

Introduction Today, it seems easy to imagine a world in which a manufacturing enterprise enjoys complete visibility and monitoring of inventory as it enters the factory, gets processed, and leaves the factory floor.

Internet of Things Design Zone. This article takes a closer look at the challenges that SIs face with OT-to-OT, OT-to-IT, and OT-to-IIoT interoperability, as well as the solutions available to ensure nonstop connectivity throughout converged networks. By Edward Lin, Moxa Download PDF version of this article While discussions about the Industrial Internet of Things (IIoT) and its promises of cost-efficient, nonstop operations carry an opportunistic tone among executives, it is system integrators (SIs) who have to grapple with the reality of figuring out how the different platforms in a network can communicate with each other. Industrial Ethernet and Wireless are growing fast — Industrial network market shares 2017 according to HMS.

Industrial Ethernet and Wireless growth is accelerated by the increasing need for industrial devices to get connected and the Industrial Internet of Things. This is the main finding of HMS Industrial Networks’ annual study of the industrial network market. Industrial Ethernet now accounts for 46% of the market (38 last year). Wireless technologies are also coming on strong, now at 6% (4) market share. Combined, industrial Ethernet and Wireless now account for 52% of the market, while fieldbuses are at 48%. Click to enlarge. Using Industrial Protocols to Connect IOT with Industry at the Edge. Conceptually, the IoT has been discussed at great lengths over the past few years. “Why IoT?” Has been asked, use cases have been explored, and many implementations are underway. The shift from concept to implementation is now sparking new discussions.

Success stories: Five smart factories – and what you can learn from them. Amazon and Adidas aren’t the only success stories in smart manufacturing, says Kayla Matthews. IIoT Platforms. 7 Industrial IoT Startups Using AI to Monitor Machines - Nanalyze. If you follow technology news and trends long enough, a few statistics pop up again and again. One oft-quoted stat goes something like this: About 90 percent of the data in the world has been created in the last two years. Now, we’ve been hearing this factoid for years, so it’s possibly time for some underemployed MBA to redo the math.

However, the bottom line: There is a isht-ton of data out there today, and more and more companies are developing ways to corral and coax that information into valuable insights for a price. Combining these big data sets with artificial intelligence, specifically machine learning, has given birth to an entire industry of predictive analytics. DUP The smart factory.