Straw bale SIPS are the alternative straw bale homes - Ecohome. Traditional straw bale home construction can be a low-tech and affordable route to a very ecologically responsible home.

There are, however, some legitimate drawbacks and challenges that can cause many people to dismiss it completely as a building technique. It seems all of these issues (some real, some less so) have been addressed by the marrying of this ancient building technique with modern pre-fab construction practices. Here is what you might have heard and already think about straw bale homes: They are too labour-intensive and therefore expensive.

They can't handle the humid climate. Building with Hemp – An Incredible Natural Insulation & Sustainable Material. The House That Rice Built — Massa Organics. Everyone is interested in energy conservation these days, and for good reason: conservation saves you money.

This point is felt especially during our sweltering summer heatwaves, when it seems that most of your paycheck goes straight to PG&E to pay for your air conditioning. There are lots of things you can do to tighten up your house, but if you are building new, then your options really open up. Because of our temperature extremes and a large amount of rice production, one of the best options for this area is building a strawbale house. In 2001, after living for several years in a leaky old farmhouse (the curtains moved when the wind blew!) Light Straw Clay OriGen Gdoc. The Advantages and Appropriate Use of Light Straw Clay. Straw clay is highly compatible with framed wall systems because it is a non-load bearing material.

Building with Light Straw Clay. Light Straw Clay Construction (New Society Publishers, 2017) by Lydia Doleman is an essential how-to guide for those looking to start light straw clay projects.

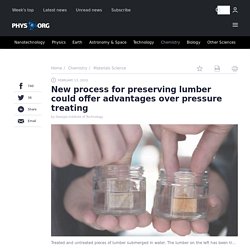

From the basics of LSC to project plans featuring LSC, Doleman gives readers everything needed to start out on their own successful projects. In the following excerpt, she goes through the appropriate ways to use light straw clay in your projects. Of the many natural wall systems to choose from, there are many reasons to choose a light straw clay wall system. Straw clay is highly compatible with framed wall systems because it is a non-load bearing material. Straw bale SIPS are the alternative straw bale homes - Ecohome. Timber construction could save millions of tons of carbon. Rockwool Exterior Insulation vs Rigid Foam. New process for preserving lumber could offer advantages over pressure treating. Pressure treating—which involves putting lumber inside a pressurized watertight tank and forcing chemicals into the boards—has been used for more than a century to help stave off the fungus that causes wood rot in wet environments.

Now researchers at the Georgia Institute of Technology have developed a new method that could one day replace conventional pressure treating as a way to make lumber not only fungal-resistant but also nearly impervious to water—and more thermally insulating. The new method, which will be reported February 13 in the journal Langmuir and jointly sponsored by the Department of Defense, the Gulf Research Program, and the Westendorf Undergraduate Research Fund, involves applying a protective coating of metal oxide that is only a few atoms thick throughout the entire cellular structure of the wood.

In their experiments, the researchers took finished pine 2x4s and cut them into one-inch pieces. More information: Shawn A. Gregory, Connor P. Aircrete: Everything You Need To Know. Embodied Carbon in Construction Calculator hopes to tackle emissions. Companies from across the architecture, engineering and construction industries have collaborated to create a free digital embodied carbon calculator that they hope will reduce greenhouse gas emissions.

The Embodied Carbon in Construction Calculator (EC3) allows architects, engineers and policy makers to easily compare potential building materials and choose the more sustainable option. The project was started by construction company Skanska and software developer C Change Labs, and realised by a non-profit alliance that includes the Carbon Leadership Forum, American Institute of Architects, Autodesk, Interface, the MKA Foundation, Charles Pankow Foundation and Microsoft. Tool is free and open-access The companies wanted to make the tool free and open-access to accelerate adoption and empower the architecture and construction industries to cut their carbon dioxide emissions.

Currently, these industries are responsible for around 40 per cent of the world's global gas emissions. Recycling concrete with added wood waste - MaterialDistrict. Researchers at the University of Tokyo, have developed a new procedure for recycling concrete with the addition of discarded wood, which results in a new building material with superior bending strength to the original material.

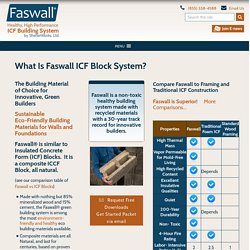

Concrete is the most common building material, but because of the large quantity of CO2 emissions it generates during production, it has come under scrutiny. Hemp and Lime v4 draft compressed 2. Faswall Healthy ICF Blocks. After World War II, amidst the rubble and destruction, a way was discovered to take the huge volumes of wood waste, grind it into chips, mineralize the chips to neutralize the natural sugars that cause rot, and bond them to cement to form a building block.

This is the genesis of the Faswall® ICF Wall Form. Since then, tens of thousands of homes, commercial buildings, and many other projects have been built in North America, Europe, and Asia with this remarkable green building system. This remains one of the preferred methods of building in Europe. It has been available in North America for thirty years. In 1987, Hans and Leni Walter of K-X Faswall International Corp. advanced the product with a patented mineralization process that allows virtually any wood or cellulose fiber to be bonded to cement.