Hydroponic lettuce automation. Reduced Work Hours as a Means of Slowing Climate Change. February 2013, David Rosnick As productivity grows in high-income, as well as developing countries, social choices will be made as to how much of the productivity gains will be taken in the form of higher consumption levels versus fewer work hours.

In the last few decades, for example, western European countries have significantly reduced work hours (through shorter weekly hours and increased vacation time) while the United States has not. This paper estimates the impact on climate change of reducing work hours over the rest of the century by an annual average of 0.5 percent. It finds that such a change in work hours would eliminate about one-quarter to one-half of the global warming that is not already locked in (i.e. warming that would be caused by 1990 levels of greenhouse gas concentrations already in the atmosphere). Report - PDF | Flash Press Release.

Why Do We Still Have to Work? In a 1930 essay called “Economic Possibilities for Our Grandchildren,” the economist John Maynard Keynes wrote that “assuming no important wars and no important increase in population, the economic problem may be solved, or be at least within sight of solution, within a hundred years.”

The Great Depression was just beginning. Few people were as optimistic as Keynes. But Keynes pointed out that in spite of the economic crisis—and in spite of the fact that many people were suffering—Europe and the U.S. were still vastly richer than they had been before the Industrial Revolution. Keynes argued that the depression did not mean that the economy was fundamentally weak, In fact, he wrote, the depression was caused by the speed with which the economy had been growing.

If productivity continued to increase by just a few percent every year, then through the miracle of compound interest we could be eight times better off in 2030 than we were in 1930. This is not the world Keynes imagined. MOPACK 100 - Moba farmpacker. Robot Serves Up 360 Hamburgers Per Hour. UPDATE: To read more about how workers will be affected by automation technology, check out Hub's follow up post Burger Robot Poised to Disrupt Fast Food Industry No longer will they say, “He’s going to end up flipping burgers.”

Because now, robots are taking even these ignobly esteemed jobs. Alpha machine from Momentum Machines cooks up a tasty burger with all the fixins. And it does it with such quality and efficiency it’ll produce “gourmet quality burgers at fast food prices.” With a conveyor belt-type system the burgers are freshly ground, shaped and grilled to the customer’s liking. And while you fret over how many people you invited to the barbecue, Alpha churns out a painless 360 hamburgers per hour. San Francisco-based Momentum Machines claim that using Alpha will save a restaurant enough money that it pays for itself in a year, and it enables the restaurant to spend about twice as much on ingredients as they normally would – so they can buy the gourmet stuff. Peter Murray Related. Algorithms that design structures better than engineers - Jordan Burgess.

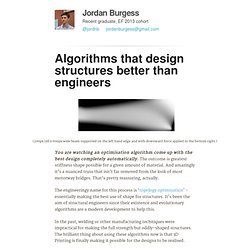

(200px tall x 600px wide beam supported on the left hand edge and with downward force applied to the bottom right.)

You are watching an optimisation algorithm come up with the best design completely automatically. The outcome is greatest stiffness shape possible for a given amount of material. And amazingly it’s a nuanced truss that isn’t far removed from the look of most motorway bridges. That’s pretty reassuring, actually. The engineeringy name for this process is ‘topology optimisation' - essentially making the best use of shape for structures.

In the past, welding or other manufacturing techniques were impractical for making the full strength but oddly-shaped structures. By specifying the restrictions and load cases, we can produce parts that can support the same forces, yet use less than half of the material. New Wave of Deft Robots Is Changing Global Industry. Why Design Now?: Contour Crafting.