DIY CAMERA MAINTENANCE/REPAIR RESOURCES - PART IV. In Part One of this series we looked at the various books which are available to help you get started.

But you may be keen to get on with repairing a particular camera. You should definitely invest a little time, first, procuring specific information about whatever problem ails your camera patient, its likely causes and potential fixes for same. The digital age we are living in has arguably been the prime cause of the decrease in popularity of film photography. But the internet means that it has now never been more convenient to seek information and advice about rehabilitating a very diverse range of film equipment.

Of course, there is always Google, but, the following list of online sites, by no means exhaustive, covers some of the online communities and independent sites where you’re likely to find information pertinent to camera repair. Forums Internet forums can be a love/hate experience for many people and photography ones are no exception. Photonet.

Automatic Transmissions: Valves and Modulators. To shift properly, the automatic transmission has to know how hard the engine is working.

There are two different ways that this is done. Some cars have a simple cable linkage connected to a throttle valve in the transmission. The further the gas pedal is pressed, the more pressure is put on the throttle valve. Other cars use a vacuum modulator to apply pressure to the throttle valve. The modulator senses the manifold pressure, which increases when the engine is under a greater load.

The manual valve is what the shift lever hooks up to. Shift valves supply hydraulic pressure to the clutches and bands to engage each gear. The shift valve will delay a shift if the car is accelerating quickly. As car speed increases, the pressure from the governor builds. When the car accelerates quickly, the throttle valve applies more pressure against the shift valve. TH350 TH400 VACUUM MODULATOR Red Stripe Turbo 350 400 Transmission w/ Extra Hose and Oring.

David Silver Spares USA - Honda CA95 BENLY TOURING USA PARTS.

6 Ways to Repair Broken Plastic. Repairing plastic items can be confounding for someone who’s never done it before.

There’s no part to replace (usually), no nut to tighten, just something… misshapen or cracked. There’s nothing to repair but the material itself. Plastic can be easier to work with than you might imagine. With some heat and some pressure many items can be fixed rather simply. So before you resign yourself to tossing a broken bit of plastic into your recycling bin, here are a few techniques you can use to repair plastic. Hot Water, Cold water This tip comes from the world of action figurine collecting. This technique isn’t just for action figures and their bent katanas.

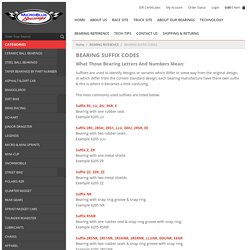

Plastic Welding with Heat If you have two separate pieces of plastic that need to be joined or if you have a crack, then you’ll need to do some plastic welding. Important: Melting plastic can be toxic, so do this in a well-ventilated area. Plastic Welding with Friction Friction welding is another way of joining plastic together. BEARING SUFFIX CODES. Suffixes are used to identify designs or variants which differ in some way from the original design, or which differ from the current standard design, each bearing manufacture have there own suffix & this is where it becomes a little confusing.

The most commonly used suffixes are listed below: Suffix RS, LU, DU, RSR, EBearing with one rubber seal.Example 6205 LU Suffix 2RS, 2RSH, 2RS1, LLU, DDU, 2RSR, EEBearing with two rubber seals.Example 6205 LLU Suffix Z, ZR Bearing with one metal shield.Example 6205 ZR Suffix 2Z, 2ZR, ZZBearing with two metal shields.Example 6205 2Z. Mazda3 Forums : The #1 Mazda 3 Forum. Announcements in Forum : Accent 3rd Gen (MC)

Moped. Bike Repair. Best penetrating oil for stuck nuts & bolts. Recently an article was passed along to me from Machinist Workshop Magazine.

They tested some commercially available penetrating oils on a group of nuts & bolts they had scientifically rusted to a uniform degree in a salt water solution. The fasteners were treated with a variety of commercially available penetrants and the measured torque required to loosen them was recorded. The break out torque required for: Nothing = 516 ft. lbs. WD-40 = 238 ft. lbs. PB Blaster = 214 ft. lbs. Edit: It was pointed out that this was a topic a few months ago , so I read through that thread and did notice someone also recommended GM 1052627 heat valve/EGR lube and I have personally used a similar Mopar EGR product for years that works very well but it is definitly more costly then used ATF and Acetone. And a final note on shop safety and penetrating fluids: I was spraying some exhaust bolts on an engine that wasn't running but was warm, when the penetrant hit the bolts it evaporated a bit.