Comment c'est fait : Le cintrage du bois. See How Upholstered Furniture Comes Together: Bed, Sofa, Chaise. When studying industrial design, you'll find most programs will have you build at least a couple of pieces of furniture, whether you're a Furniture Design major or not.

But the main output always seems to be in wood or metal, with most programs simply too short on time to teach the art of upholstery. So it's helpful, we think, for the aspiring but inexperienced furniture designer to see how upholstered furniture comes together. Your program has undoubtedly taught you rudimentary wood-joining, and maybe you've learned to weld and finish with an angle grinder, but there's an entire science of straps, webbing, springs, nails, tacks, foam, glue, fabric, buttons and thread you may have never seen. LA FABRICATION DU AA BY AIRBORNE. Artek: the making of the patented L-shaped stool 60 by alvar aalto. Jan 31, 2014 artek: the making of the patented L-shaped stool 60 by alvar aalto artek / vitra: the making of the patented L-shaped stool 60 by alvar aalto the focus on wood processing and the collaboration between otto korhonen in the 1930s led to the development of innovative ways of bending wood, resulting in the bent L-shaped leg – which was patented in 1933 – and alvar aalto’s classic ‘stool 60′ by artek. standardized construction, an idea championed by alvar aalto, paved the way for socially oriented design and architectural planning, and mass production methods for manufacturing. the L-leg was followed in the 1940s by the Y-leg, and in the 1950s by the X-leg. otto korhonen’s expertise of woodworking techniques, combined with aalto’s visionary sense of form and his mastery of technology, created the foundation for the birth of the design collection. to see the iconic stool produced from raw plank to polished furniture, watch the video below: sanded seat-pans ready for assembly.

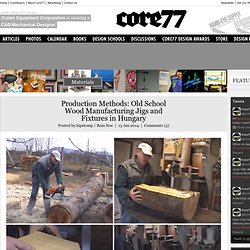

Production Methods: Old School Wood Manufacturing Jigs and Fixtures in Hungary. At eight-minutes-plus, this production methods video is longer than the average internet denizen's 2.5-minute attention span, but anyone who makes things out of wood will find it fascinating.

This unnamed Hungarian craftsperson shows you every step as he goes from felled tree to cutting board, and what's most interesting is the dedicated series of jigs, rigs and fixtures he's come up with to speed up his production, as well as the combination of machines he uses. Be sure to check out: Coup de coeur PDW 2013 : Chaise Baby Blue par Paul Venaille. Coup de coeur PDW 2013 : Chaise Baby Blue par Paul Venaille.

Wishbone Chair by Hans J. Wegner for Carl Hansen & Søn. Even if you’re not a design fanatic and don’t know its name, chances are you’ve seen or even sat in the Wishbone Chair.

In production for over 60 years, this classic dining chair, designed by Danish designer Hans J. Wegner for Carl Hansen & Søn, is simple in design but handmade with the finest craftsmanship possible. Furniture Made Using Wind by Merel Karhof. Designer Merel Karhof’s collection of upholstered furniture pieces, called Windworks, is made using materials produced using wind power, an inexhaustible, and free, energy source.

Watch the video for a little insight into the production process: In 2010, she set up the ‘Wind Knitting Factory’, which is a completely wind-powered knitting machine where when it’s windy, the machine knits quickly and when it’s calm, it knits more slowly. While generally the machine knits things like scarves, Karhof decided to go bigger and upholster furniture. Karhof began the collaboration between three millers, that included a saw miller, a color miller, and a knitting miller (herself), in the northern part of Holland where windmills are common. Each of the well-preserved windmills in the area produces a different type of raw material. The wood gets cut and assembled at the sawmill and then transported by the river to the pigment mill.

The Office for Lost Objects™ Friend of The Office and filmmaker Paul Rogers expertly wove together a story for us—a story that, on the surface, describes the process of making a 10º Step Stool, and going deeper, illuminates the particular passions and motivations of the designer (us) and craftsman/producer (Paul Morrison of The Wood Cycle).

At The Office, we're not just about furniture design. We're about art, creativity, and design of all kinds. See more of the design we do. NOTCOT.ORG. The Thread Wrapping Machine by Anton Alvarez. Threads and glue replace joints and screws in the furniture that emerges from a custom-made machine designed by Royal College of Art graduate Anton Alvarez (+ movie).

Need to Get a Complicated Pattern Onto a Complicated Surface? Check out Dip Coating. Industrial design is a broad profession, which is a good thing for the Core77 Discussion Boards.

No matter how deep your area of expertise, at some point you'll run into an issue that someone with expertise in a different area under ID's broad umbrella can help answer. We first caught wind of Matt Binns (he of the Giant Globes) when he popped up on the Core77 boards inquiring about how these things are produced: Those are a series of gardening tools sold by the UK's V&A Museum, each covered in a William Morris print from 1864. Any idea how they got the pattern onto the steel tools? Production Methods: Metal Spinning (to Make a Planter by Brendan Ravenhill) Posted by Ray | 12 Sep 2012 | Comments (0) We've seen some of Brendan Ravenhill's work in the past, from a broad survey to a closer look at specific projects as well as a few appearances in our photo galleries circa 2010/2011.

For his latest project, the "Spun Metal Planter," the Los Angeles-based designer has produced a video about the manufacturing process that imparts the vessel with its distinctive shape and indeed its inspiration. Arm Knitting Revisited via Giant Hand-Knit Furnishing Series. Stitching with string gives way to knitting with sticks, which in turn yields finger and arm knitting, an engaged way to wrap and twist your way right into the design and build process. Andrea Brena took some time off from school to get his hands dirty (or at least brightly-colored), dabbling in the old art of arm knitting using trashed textile scraps from chairs, couches, carpets and pillows.

The result are a neat series of rugs, seats and more, all created with a physical process in which the body is involved on a high level, almost like a dance or hand-carved sculpture. Charge Bikes x EADS: 3D Printing Titanium Parts for a Bicycle Frame. Posted by Ray | 20 Aug 2012 | Comments (3) 3D printing has been heading into uncharted territory of late, what with a recent, as-yet-unresolved IP debate. Yet while the DIY/consumer-oriented 3D printers are typically designed to extrude thermoplastics such as ABS, I (for one) didn't realize that 3D printing can also be used to make metal parts in a similar fashion.

One commercially available process, electron beam melting (EBM to those in the know), has been around for upwards of a decade and its major applications include medical implants and aerospace engineering. Alternately, as commenter Modul notes, metal objects can also be digitally fabricated in what is known as Direct Metal Laser Sintering (DMLS), which allows for a higher level of detail but requires postprocess thermal treatment, which is not necessary with EBM (a detail comparison of the two processes can be found here). Production Methods: Thermal Drilling. In addition to friction welding, there's another production method that exploits heat from friction to perform operations in metal: Thermal drilling. With thermal drilling, a conical bit is rotated at high speed and driven into sheet metal or the walls of metal tubing.

The heat generated deforms the material at the point of contact, allowing the bit to push through. But what's especially neat here is that material is not excavated, as with drilling a hole with a conventional twist bit; instead the heated material is actually formed into a bushing within the workpiece itself, providing a convenient mounting point for a fastener. And yes, it can be tapped. NOTCOT.ORG. Pressed Chair by Harry Thaler for Moormann. The Film. Pressed Chair by Harry Thaler for Moormann.

The Film. Via @smowblog, a short film on the making of the iconic Pressed Chair by Harry Thaler for Nils Holger Moormann. Says Smow, "If there is a chair on the market at the moment that better symbolises how complex simplicity in design is than Pressed Chair by Harry Thaler for Moormann. Production Methods: Friction Welding. Friction welding is the process by which two pieces of metal are fused together by rotating one of them at high speed, then pressing the two together. Take a look: One advantage of friction welding is that you needn't clean the pieces before bonding them; the friction cleans the materials as they grind together, and centrifugal force migrates any dirt to the outside.

How Chesterfield Sofas are Made. To some older folk the word "Chesterfield" means sofa, any old sofa; but to the rest of us, it's that particular type of leather sofa with the curled-over arms and the distinctive, tufted upholstery. What's amazing is just how many components go into the thing: Rip one apart and you'll find a wooden frame, several types of metal springs, fabric straps, stuffing between the springs, foam inside the cushions, the leather, the buttons, the thread to hold those latter two together, and tons of upholstery tacks and staples. We will of course save you the trouble of having to find a Chesterfield you can rip open. While no one online spells out exactly how they're made, I've found two excellent videos that really give you a sense of how they come together, and in what order.

The first vid, from the UK's Saxon Leather Upholstery, shows things happening at a factory pace: Kruysman-Proto. Leica M9 Hermés Special Edition. Video. ATOMIK INSIGHT. CNC Panel Joinery Notebook. NOTCOT.ORG. Production Methods: Arne Jacobsen's Series 7 chair. Made by Hands: Yet Another Beautiful Manufacturing Video.

Smoke! video by Gwenael Lewis. Forget Commercials: Make a Good Craftsperson Video. Gravity by Jólan van der Wiel. NOTCOT.ORG. Over mold wooden furniture. La collection de Zieta pour la première fois sur Maison & Objet. Il y a 3 ans maintenant, Oskar Zieta faisait sensation avec la présentation du tabouret Plopp… Une pièce iconique qui dévoilait une technologie révolutionnaire développée depuis plusieurs années par l’ingénieur et son acolyte, Philippe Dohmen. Le procédé, appelé FIDU (Freie InnenDruckUmformung – libre déformation sous pression interne), commence par la découpe au laser de deux patrons en tôle qui sont ensuite soudés sur leurs contours.

On y introduit alors de l’air ou une autre matière sous pression afin de former le volume de la pièce. Si la phase de production en 2D est contrôlée à 100%, le processus de déformation de la tôle, quant à lui, échappe dans certaines limites au designer, faisant de chaque pièce un produit unique, malgré une production série. Time Bicycles: Carbon Fiber Weaving and Resin Transfer Molding.

Tree-D Printing by Freedom of Creation. The Making of The Fiberglass Chair. Vidéo: Ben Kandel. Véritable art, le tournage sur bois mérite amplement un petit focus surtout quand la vidéo est super bien réalisée (merci encore le Canon 7D) et l’ébéniste jeune et adorable ! Comme l’explique Ben Kandel, il est tombé dans le tournage sur bois étant petit grâce à un voisin de sa grand mère et depuis il ne lâche plus sa machine.

Hyper-Flexible Wood Notepads Bend the Rules of Materials. Technology should be used to make our lives easier and better – there’s no doubt about it. The creative types at Snijlab agree: the Rotterdam-based service uses their computer-controlled laser cutter to make products on demand. Max Lipsey’s Acciaio Series. It was hard not to feel a burst of pride when, after introducing Matter’s Jamie Gray to Max Lipsey in advance of his appearance in our 2011 Noho Next showcase, we heard the pair had a major collab in the works. LEGO...The Building Blocks of Fun! Max Lamb. Weaving the Wishbone Chair at the Carl Hansen & Son Showroom Opening.

Making of M3 Chair by Thomas Feichtner. Dezeen Screen » video Archive » Tales of the Hunt: Maarten De Ceulaer. How Zippers Are Made. Just One More Piece of Toilet-Related Manufacturing Goodness. How Toilets are Made. How Pencils are Made. Manufacturing Vid: A Sheet of Steel's Journey from Roll to Finished Car. Blast by Guy Mishaly. Deconstruction: Z Table by Hellman-Chang. How to make Balloons: Object Design League's Balloon Factory at the MCA Chicago. Printer produces personalised 3D chocolate. Behind the Scenes: Making of a Leica Lens. The Making of Tom Price’s Meltdown Chairs on Tales of the Hunt. SunCutter : markus kayser. Raw Studios. John Cho Moore: Beauty Through Bamboo. Pod by Benjamin Hubert for De vorm. Birth of a Spraycan. IKEPOD : La fabrication du sablier dessiné par Marc Newson (english below) Video of Lexus' 360-Degree Carbon Fiber Loom. FROM STEEL: The Making of a Soulcraft. Roy's Jeans - Video by Self Edge. Product by Process » Blog Archive » Eames Lounge and ottoman.

Personal Factory (tm) - design, make & build your own custom products. Product by Process. Product by Process » Blog Archive » Bike Rims : H plus son. Production Methods circa 1947: Bookmaking Sure Provided a Lot of Jobs. How the Branca chair is Made. Deconstruction: Dansk Stole by James Killinger. How Globes Are Made. How Jeans are Made. Production Methods: Cool Demonstrations of Metal Spinning.

Film: The Aluminium Chair by Eames Demetrios. MOVIE 1. The Submarine Chair, part 1: Making of. Thermoformage du Solid Surface– HI-MACS® Rekiem Skateboards, fabrique artisanale de planches à roulettes. Rekiem Skateboard – How to make a board. Cycle de fabrication optimale - Production. Monkee Design - Industrial Design Blog/ Student Resource - Will We Print Our Clothes In The Future. SketchChair, le logiciel ultime pour designer des prototypes de chaises, de fauteuils, etc. Airpiano. Découpe panneaux - Gregg Fleishman Studio. How to build an Eames Shell Chair? WINKLER : cintrage bois. Cool Moving table deco. Dentelles de métal par Cal Lane.