MakerBot Founder: 3D Printing and the "Next Industrial Revolution" 3DPrinting: 3D printing basics explained. Archives for the category: 3D printing basics explained March 5, 2014 The Father Of 3D Printing Inducted Into The National Inventors Hall Of Fame The first functional 3D printer prototype was built way back in 1984.

This year, its inventor, Chuck Hull, is being inducted into the National Inventors Hall Of Fame. [via TechCrunch] This puts him up in the ranks, in the U.S. Read more. emily | 7:09 PM | permalink March 4, 2014 Sneak Peek: The 3-D Printing Boom Gets a Documentary It seems hard to believe that the world of 3-D printing has been around long enough to warrant a documentary—Bre Pettis’ company MakerBot has been around barely five years—but yet one is already in the can. "Print the Legend" (teaser above) follows the “Macintosh moment” 3-D printing has had over the last few years. [via Wired] Kinematics - System for 3D printing complex, foldable forms / by @nervous_system. Developed by Nervous System, Kinematics is a system for 3D printing that creates complex, foldable forms composed of articulated modules.

The system provides a way to turn any three-dimensional shape into a flexible structure using 3D printing. The system combines computational geometry techniques with rigid body physics and customisation to take large (flexible) objects and compress them down for 3D printing through simulation. The process begins with the form design of the desired object. Watch a new 3D printing technique create intricate objects from a pool of goo. 3D printing is stuck in a bit of a rut.

There are companies trying to push the technology beyond the trinket market, but many of the existing printers are slow, jam often, and don’t always make perfect copies. One new printer introduced at the TED conference may have the answer. Most existing consumer-grade 3D printers print in layers that fuse together to make the final object. Carbon3D takes a different approach, by pulling a seamless object out of a pool of photosensitive resin: Carbon3D CEO and co-founder Joseph DeSimone, a chemical engineering professor at the University of North Carolina with more than 150 patents to his name, said he and his team were inspired by the T-1000 robot from Terminator 2, and what they created seems right out of science fiction.

Here’s how it actually works: A light shines through the pool of resin, which causes the resin to harden. EMERGING OBJECTS. EMERGING OBJECTS. O que é o Maker Innovation e a rede Fab Lab? 20 Amazing Creations You Can Make With 3D Printing. If you can print in 2D, can you print in 3D?

Well, the technology is already here. You can print out 3-dimensional objects based on a working template, and they aren’t just for show. Will 3D Printing Upend Fashion Like Napster Crippled the Music Industry? Before MakerBot, no one could have conceived of Napster for fashion.

A Burberry trench couldn't be replicated digitally, which meant the garment industry was more or less safe from the revolution that upended music production and book publishing. But with 3D printing, Fifth Avenue is headed for its own disruptive moment. 3D printers can manufacture spare parts for spacecraft, produce food and housing, even replicate human organs. Além da impressão 3D: Microfábrica imprime, fresa e corta. Mecânica.

3D printer can build a house in 20 hours. ‘Anti-Gravity’ 3D Printer Uses Strands to Sculpt Shapes on Any Surface. New flexible materials pave the way for 3D-printed clothing. Most 3D-printed objects are made out of rigid plastic or resin materials that aren't necessarily ideal for every project.

Now, for a limited time online shops like i.materialise are offering designers the chance to play with experimental materials that have properties akin to rubber. Currently these materials are only being offered on a limited basis, but they're already paving the way for new ideas, including one haute couture dress that paraded down the catwalk at Spring Fashion Week 2013 earlier this year. The new material, which is dyed black and called Rubber-like, is priced at €2 (US$2.60) per cubic centimeter, which is more expensive than other options.

However, this is one of the few materials available that frees designers to incorporate shock absorption and structural elasticity into their models, gadgets, and functional objects. One of the more exciting possibilities afforded by this material is 3D printed clothing, as can be seen in the following video. Silkworms work with robot to make 3D-printed dome. A dome has been created by teaming up a 3D-printing head on a robotic arm — and a swarm of 6500 silkworms.

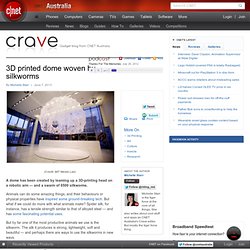

Animals can do some amazing things, and their behaviours or physical properties have inspired some ground-breaking tech. But what if we could do more with what animals make? Spider silk, for instance, has a tensile strength similar to that of alloyed steel — and has some fascinating potential uses. But by far one of the most productive animals we use is the silkworm.

The silk it produces is strong, lightweight, soft and beautiful — and perhaps there are ways to use the silkworms in new ways. In order to explore the potential relationship between digital and biological fabrication, MIT Media Lab's Mediated Matter research group has created a project called Silk Pavilion — a 3.65-metre diameter dome that is a collaboration between human designers, machines and grubs. The robotic arm, onto which was attached a 3D printer head, created the primary structure. Via matter.media.mit.edu.