Roman seawater concrete holds the secret to cutting carbon emissions. Public release date: 4-Jun-2013 [ Print | E-mail Share ] [ Close Window ] Contact: Paul Preusspaul_preuss@lbl.gov 510-486-6249DOE/Lawrence Berkeley National Laboratory The chemical secrets of a concrete Roman breakwater that has spent the last 2,000 years submerged in the Mediterranean Sea have been uncovered by an international team of researchers led by Paulo Monteiro of the U.S.

Department of Energy's Lawrence Berkeley National Laboratory (Berkeley Lab), a professor of civil and environmental engineering at the University of California, Berkeley. Roman concrete. Roman concrete, also called opus caementicium, was a material used in construction during the late Roman Republic through the whole history of the Roman Empire.

Roman concrete was based on a hydraulic-setting cement with many material qualities similar to modern Portland cement. By the middle of the 1st century, the material was used frequently as brick-faced concrete, although variations in aggregate allowed different arrangements of materials. Further innovative developments in the material, coined the Concrete Revolution, contributed to structurally complicated forms, such as the Pantheon dome.[1] Roman concrete was also used to make roads. Historic references[edit] Caesarea is the earliest known example to have used underwater Roman concrete technology on such a large scale. Vitruvius, writing around 25 BC in his Ten Books on Architecture, distinguished types of aggregate appropriate for the preparation of lime mortars. Material properties[edit] ERO Concrete De-Construction Robot. Bio Concrete, Concrete That Repairs Itself.

Can 'Green Cement' Make Carbon Capture and Storage Obsolete? Calera and Novacem use concrete to capture CO2 » Innovation Toronto. Image via Wikipedia It just looks like mud, and appears to do nothing except sit there and harden. The fact is, though, concrete is the world’s third-largest source of man-made carbon dioxide. Calera Expands Options for Capturing Carbon. Nature isn’t as bountiful as once anticipated, Calera has learned.

The sometimes controversial startup originally focused on the idea of mixing carbon dioxide with seawater containing traces of calcium and other minerals to produce calcium carbonate, one of the key ingredients in cement. The process -- ideally -- would sequester greenhouse gases from power plants and industrial sites fairly inexpensively and curb the need to mine carbonates, an energy intensive process, for the construction industry. A key element to the concept involves exploiting exotic polymorphs, or forms, of calcium in sea water to minimize the amount of energy and additional raw materials required to turn flue gases into a solid. It turns out, however, that the brines infused with the appropriate feedstocks aren’t as common as once believed, says new CEO Will Roach, and they often aren’t located right next door to power plants.

“The ideal [feedstock] would be naturally occurring, abundant and free. Studio Edirisa » Blog Archive » 1cm of concrete + cloth + chicken mesh = the death of the iron sheet? Role models & bad models21 May 2010.

Overview « Novacem. Novacem has developed a new cement based on magnesium oxide which will address the carbon problem faced by the cement industry, and as a result will contribute significantly to an overall shift to a low carbon world.

Production of our cement is carbon negative; more carbon dioxide (CO 2 ) is absorbed during the process than is emitted. We aim to offer cost parity with traditional cement, even before any cost of carbon is factored in, and also performance parity. Abundant accessible sources of the magnesium silicates we use to produce magnesium oxide exist on Earth, and will support large scale roll out of Novacem cement production. Our long term vision is to be adopted on a broad basis and eventually to represent a significant percentage of cement industry production. Www.concretecanvas.co.za/Docs/1206 CCSA Data Sheet.pdf. Ncrete Canvas - Rapidly Deployable Infrastructure. Improved Concrete Via Use Of Sunflower Seed Husks. Recycling Published on May 1st, 2013 | by James Ayre An improved form of concrete, made by utilizing a waste material of the agricultural industry — sunflower seed husks — has been created by researchers at the Namik Kemal University in Turkey.

The husks are a waste product of the vegetable oil and food industry, and are produced in enormous quantities, so any potential use for them would be a big plus with regards to waste reduction. Constructionindex.en.html. Welcome/Home Construction Index ... ferrocement.com Section 1 ...

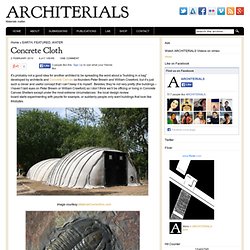

Concrete Cloth. Home » EARTH, FEATURED, WATER 2 February 20106,411 viewsOne Comment It’s probably not a good idea for another architect to be spreading the word about a ”building in a bag” developed by architects and Concrete Canvas co-founders Peter Brewin and William Crawford, but it’s just such a clever and useful concept that I can’t keep it to myself.

Besides, they’re not very pretty (the buildings – I haven’t laid eyes on Peter Brewin or William Crawford) so I don’t think we’ll be officing or living in Concrete Canvas Shelters except under the most extreme circumstances: the local design review board starts experimenting with peyote for example, or suddenly people only want buildings that look like trilobytes. Image courtesy MaterialConneXion.com Image courtesy theguardian.co/uk. AAC Blocks - AAC Panels.