How to Select a 3D Printer. 3D Printing Month. Www.scantech.com. The Original Egg-Bot - Home. Affordable, Easy-to-Use 3D Printers. FORMIGA P 110 - laser sintering 3D printer for rapid prototyping – EOS. FORMIGA P 110 is a flexible, cost-efficient and highly productive system for the Additive Manufacturing of polymer parts.

This compact system is ideal as an entry into Additive Manufacturing, for example for cost-efficient small series production, customised products with complex geometries and rapid prototyping applications. Without requiring tools, the system makes direct use of digital CAD data to produce polymer parts of the highest surface quality to a maximum construction height of 330 mm. Innovation Additive Manufacturing of polymer products directly from CAD data within just a few hours Cost-efficient, batch-size appropriate production Flexible balancing of component requirements (mechanical criteria, surface quality, consistency of form, etc.) with the greatest possible cost efficiency through the use of suitable EOS parameter sets Quality Sustainability Efficiency Flexibility.

Origo a 3D printer for mom, dad and the entire family. Home. Fab@Home - Make Anything. Rapid Prototyping Technologies. Rapid Prototyping Technologies & Manufacturing Roland subtractive rapid prototyping machines provide snap-fit, functional parts and prototypes milled from a wide variety of materials with smooth surface finish, tight tolerances and a low cost of ownership.

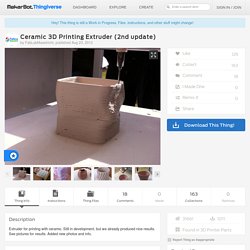

Wide choice of materials. Choose from a wide range of non-proprietary materials, including non-ferrous metals, acrylic, chemical wood and popular engineered plastics such as ABS, Delrin and nylon. View material selection. Smoother surface finish. Compared to 3D printers, Roland's rapid prototyping machines deliver smooth surface finish without post finishing, as well as tight tolerances up to +/- 0.001mm. Ceramic 3D Printing Extruder (2nd update) by FabLabMaastricht. We have created an extruder based on the design of Unfold.

We have added a syringe holder and a few more parts to attach it to the printer. We used a 0.5 mm, 1.2 mm and a 1.6 mm nozzle as an experiment. But we have 30 other different nozzles, so we will keep trying to get the right nozzle. We bought a set of different nozzles in order to experiment with different sizes and lengths of the nozzles. You could also buy a set of 50 pieces of one type of nozzle. We have also been creating different mixes of the ceramic, but we think that we have found a good mix that is strong enough to make thin walls. If you would like to build your own, you will need the following things: Laser Cutting, Engraving and Marking Equipment, Machines and Software. Cutting Systems, CNC Plasma Cutting machine, CNC plasma table. Technical Information | Owners Community Copyright ©2008 PlasmaCAM, Inc.

<div style="display:inline;"><img height="1" width="1" style="border-style:none;" alt="" src=" [^] </div> Epilog Laser Engraving Systems - Laser Systems for Engraving, Cutting and Marking. EGX-30A Desktop Engraver. Portable Milling Machine. MDX-40A SRP Specifications. The Largest Machinist Community on the net! CarveWright. LYMAN FILAMENT EXTRUDER II by hlyman. A Cliever. The Foetus Project by Jorge Lopes Dos Santos. Brazilian design graduate Jorge Lopes Dos Santos has developed a way of making physical models of foetuses using data from ultrasound, CT and MRI scans.

He developed the project in collaboration with a paediatric cardiologist at Imperial College while studying on the Design Products MA course at London's Royal College of Art. Jorge Lopes Dos Santos hopes the models, which are made using 3D printing techniques, can be used to train doctors and to help with emotional support for parents whose child may be born with deformities. See all our stories from the RCA show 09 in our special category. Here's some more information from the RCA, followed by a text from head of Design Products Ron Arad: Medicine is benefiting from cutting-edge research undertaken in the Design Products department at the Royal College of Art.

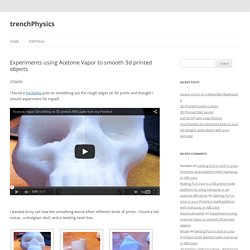

“Something that staff and students are doing is working with cutting-edge technology, digital technology, 3D printing,” French said. Ron Arad: The other examiner in the room was Dr. Experiments using Acetone Vapor to smooth 3d printed objects. I found a hackaday post on smoothing out the rough edges on 3D prints and thought I should experiment for myself.

I wanted to try out how the smoothing would effect different kinds of prints. I found a tall statue , a shotglass skull, and a twisting heart box. I collected all of the items that I’d need according to the video. The items where AcetoneWire hangerBottom of a soda can Glass jar with lidPrintrbot I set my Printrbot to 110c through Pronterface. The jar I was using started to form condensation of acetone on the walls in about a minute. The first model I used was the statue from thingiverse : I took the model out every few minutes, you can see the progress in the gallery bellow. Tutorial: Creating multi-color prints using a one-colour 3D printer. By Andre Tiemann | Feb.12, 2013 As someone that is very active in the prosumer range 3D printer market (primarily through my efforts over at Draft Print 3D), I have embraced the immense potential offered by the technology.

The ability to create three-dimensional prototypes and production ready parts on the fly still boggles my mind at times. Shapeways. HelpTutorialsHow to use MeshLab and Netfabb for fixing your model This tutorial provides a step-by-step overview on how to convert a .dae, .x3d or .wrl into a .stl file using Meshlab and Netfabb.

In addition, it covers how to check your file for printability and fix some of the most frequent problems. Requirements Before we get started please download and install the following 2 software programs. You will need these along the way.