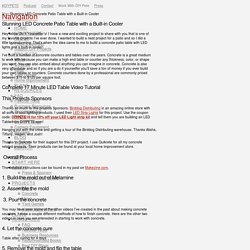

Stunning LED Concrete Patio Table with a Built-in Cooler. Hey fellow Do It Yourselfer’s!

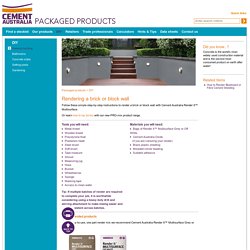

I have a new and exciting project to share with you that is one of my favorite projects I’ve ever done. Industry Standard Guides on How to Render a Wall, Cement Products and Services. Step 1: Preparing the surface Remove any paint, laitance, plaster or any other loose material that may prevent good adhesion with a steel brush.

Remove any brittle mortar in the joints of brick or block walls. To protect the area from spilt render, cover paths or driveways with black plastic sheets and mask any other exposed surfaces you wish to keep clean. Excellent Tutorials on Mixing Concrete and Cement Goods for Commerce. Packaged products > Hints & Tips Select your question below What is the right consistency for good quality concrete?

What mix ratio should I use for a path or driveway? What Personal Protective Equipment (PPE) is required when handling cement based products? Leading Enterprise Cement Goods and Professional Guides on How to Cement. Measure, mark using a Carpenters square, cut squarely and nail the formwork together so that the internal measurement is the required dimensions for the slab.

With square or rectangular slabs, ensure that the formwork is true to square by measuring the diagonals between the opposite corners - these must be equal for the shape to be correctly square. Tip: The height of the timber used for your formwork should equal the thickness of your concrete slab to enable you to screed the finished surface level with the top of the formwork. Step 2: Measure the area to be dug out Place the formwork in situ and use a spade to mark around the outside edge of the formwork.

Top Cement Products for Industry, Services and tutorials on the Difference Between Concrete and Cement. Packaged products > Hints & Tips Select your question below What is cement?

22 Seriously Cool Cement Projects You Can Make At Home. Highly Effective and Long-Lasting Coloured Concrete in Australia. Packaged products > Our products The Cement Australia Oxides range includes 10 different colours available in a range of 4 different pack sizes to suit the requirements of your project.

First Rate Blue Board Rendering Products for Business Solutions. Step 1: Preparing the surface to be rendered To protect the area from spilt render, cover paths or driveways with black plastic sheets and mask any other exposed surfaces you wish to keep clean.

Fix the corner beading to the external corners of the surface to be rendered using an approved adhesive ensuring it is straight and plumb to provide a neat rendered finish. When rendering blueboard surfaces use a 50mm fibreglass self adhesive tape to help prevent cracking and crazing in the joints between the sheets and other abutting structures. The tape is embedded in the joint ensuring that it does not bulge and a thin coating of render is plastered over it to the thickness of the recessed edges.

This ensures a flush finish to accommodate subsequent applications of render. Tip: You can use Render It™ to attach the beading to the external corner if you don't have an approved adhesive available. Step 2: Mixing the render Only mix one bag of Render It™ at a time. Step 3: Applying the render. Good Quality Tips and Guides on How To Render a Wall for Industry and Commercial Purposes. Ideal Cement Products and Tips on How To Mix Concrete Effectively for Commerce. Concrete Masonry Association of Australia - CMAA. Leading Concrete Strength and Cement Goods for the Business Sector.

Good Quality Cement Suppliers in Australia for Construction Goods and Solutions. Australia’s leading supplier of cement products and services, Cement Australia delivers to the nation’s leading industrial companies including major concrete producers, building and engineering contractors, and some of the nation’s largest mines.

Bulk products are delivered in large quantities by pneumatic tankers and require a silo for storage. To find out more about Cement Australia’s wide range of bulk products and services, click on the links below. Cement, Flyash, Lime & Slag: we offer a range of cementitious materials > Read more Customer support: Our Customer Interface Team (CIT) provides a single and convenient point of > Read more Project solutions: Many of today’s major projects such as tunnels, dams, bridges and highways require specialist > Read more Sustainable products: We are committed to providing sustainable alternatives.

Cement Concrete & Aggregates Australia. First Rate Cement Products and Pre Mix Concrete for Enterprise and Services - Cement Australia. Packaged products > Hints & Tips Select your question below How many bags of pre-mixed Concrete Mix are required to fill a cubic metre?

How many standard bricks and blocks does a bag of mortar lay? What does the term MPa mean? How many days after application can I paint render? Does paint need to be removed from a surface before I render it? National Precast Concrete Association Australia - Cement Goods for Commerce, Services and Concrete for Garden Slabs. Top Quality Concrete for Garden Slabs and Additive Products for Building Works and Services. Ideal Pre Mix Concrete Goods for Enterprise and Services - Cement Australia. How to Join Bamboo. How to join bamboo, or what are the best bamboo joints? Well first of, it is important to know a few basics principles about joining bamboo before discussing the different techniques.

So here goes... Do not use green, fresh cut bamboo. Bamboo has to be completely dry before using it in construction (preferable air dried). During the drying process the bamboo diameter shrinks, so when bamboo is used in joinery this will result in lose and weak joints after a few weeks.Do not use bamboo when it is less then 3 years of age. Do not use conventional wood nails in bamboo joinery, they will cause the bamboo to split. When using bamboo as a column make sure that the lower part connecting with the surface ends with a node. Bamboo Has Nodes, Use Them! In construction, using the bamboo nodes is very important. Often it isn't possible to find bamboo of the required length with both end nodes in place.

Bamboo Cuts These are the most common cuts to use when making bamboo joints: 1. 1. Landscape Architects Network - Revealing the environment. Tiny House Design. Innermost House / Photo Gallery / An Innermost Life. Tiny House Living brought to you by Tiny r(E)volution — Tiny House living brought to you by Tiny r(E)volution. Homes Delivered and Constructed On-Site. Best Pro Mix Mortar Product Range for Commerce and Do-It-Yourself Projects. Cement Australia - Top-rated Concrete Products for Industry and Solutions. Packaged products > Our products > Just add water Quality blend of cement, sand and aggregate Great for small jobs Convenient & easy to use Use our simple Calculator to work out the requirements for your project Applications plus paths and footings General information A blend of cement, aggregate and sand, designed for use in projects where a quality concrete is required.

Instructions STEP 1 If using a concrete mixer, add water (exactly 2.5 litres of clean water per bag of Concrete Mix) to the mixing vessel. OR if using a wheelbarrow, place Concrete Mix in the barrow, create a hollow and add 2.5 litres of water per bag and mix. STEP 2 Place the well mixed concrete in the formwork filling all corners, and compact. Available sizes 10kg, 20kg.