Our Major Clients are Pulp & paper industry. We work with organizations of all sizes and shapes across all industries, with most of our clients being large global organizations.

Our customers are our customers because they value the service we provide, appreciate our global mind-sets, and respect our adherence to the created search model. The candidates we hold meet and often exceed expectations. They experience great career growth and work with our client companies for a very long time. Pulp & paper industry APPLICATION : Clarification of backwater from paper machine to recover fibre for reuse and clarified water for all fresh water applications and of deinking wash water. DAIRY INDUSTRY APPLICATION : Primary Clarification of effluents coming from washing operations of equipments and floor to bring B.O.D. down to acceptable standards. TANNERY APPLICATION : Primary clarification of composite effluents except soak-liquor. Advanced DAF system Technique. Krofta clarifiers have retention times as low as 3 minutes and with a possibility of resource recovery in some cases as opposed to the sedimentation methods characterised by very long retention times.

Krofta, is the world leader in this field having more than 1200 installations running successfully all over the world. The advanced DAF system offered by Krofta does not warrant a separate flocculation tank, flocculation mixer, flash tank and flash mixer. The Air Saturation Tank of yesteryears is replaced by the patented Krofta Air Dissolving Tube (ADT) which provides effluent saturated with air in residence time of 10 seconds.

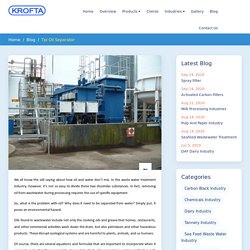

Air requirement is also very low as compared to the DAFs of earlier designs. Salient features / benefits of Krofta DAF clarifiers are: Total steel fabrication and negligible civil work facilitating relocation, if needed. Krofta Engineering. We all know the old saying about how oil and water don’t mix.

In the waste water treatment industry, however, it’s not so easy to divide these two dissimilar substances. In fact, removing oil from wastewater during processing requires the use of specific equipment. So, what is the problem with oil? Why does it need to be separated from water? Simply put, it poses an environmental hazard. Krofta Engineering.

Seafood-wastewater-treatment. Megacell. Megacell. Belt Filter Press Systems. DAF In The Dairy Industry. Krofta Engineering. Krofta Engineering. Dissolved-air-flotation-india. Krofta Engineering Limited–India’s No 1 Leading Technology DAF. Unicell- Dissolved Air Flotation Clarifier. Wastewater treatment equipment. Advanced DAF system Krofta. Krofta clarifiers have retention times as low as 3 minutes and with a possibility of resource recovery in some cases as opposed to the sedimentation methods characterised by very long retention times.

Krofta, is the world leader in this field having more than 1200 installations running successfully all over the world. The advanced DAF system offered by Krofta does not warrant a separate flocculation tank, flocculation mixer, flash tank and flash mixer. The Air Saturation Tank of yesteryears is replaced by the patented Krofta Air Dissolving Tube (ADT) which provides effluent saturated with air in residence time of 10 seconds. Air requirement is also very low as compared to the DAFs of earlier designs. Salient features / benefits of Krofta DAF clarifiers are: Total steel fabrication and negligible civil work facilitating relocation, if needed. Contact for Dissolved Air Flotation. Leading manufacturer and supplier. Pressure Filter is a closed cylindrical vessel either vertical or horizontal (mostly vertical) containing the filter media over a collector system.

Water flows from top downwards percolating through the media and is drawn off through the collector system at the bottom. Cycle of operation include back washing with or without air scouring, short rinse to waste and return to operation. The filter will effectively give clarified water having suspended solids to less then 20 ppm. The filter will have to be washed with Clarified water periodically. Advantages Vertical / Horizontal Designs ,Strainer/Header-Lateral Collection Systems. Applications Preparation of Cooling water, Treatment of Wastewater Thermoelectric Power Plant, Pre-filtration for membrane systems Filtration of gray water or Surface water, Production of drinking water, Swimming pool water download Detail about Pressure Sand Filter. Oil Water Separators.

We have made a technical collaboration with Stetfield Separators Limited,UK for their Oil Water Seperator like CPI & TPI to market their equipments in across the globe.

Our Oil Water Separators are designed as per following specifications: Corrugated and Tilted Plate Separators Stetpack tilted or corrugated plate interceptors offer enhanced gravity separation of immiscible liquids via inclined parallel plates and coalescing media. Solid Liquid separation solutions, DAF.