Krofta Engineering — Complete Milk Processing Plant Equipment:... Krofta Engineering — Suppliers of machinery and equipment for the... Oil extraction machine manufacturers. Carbon black. Paper Machinery (1) Oil Extration Machine. Dairy effluent. Waste Water. Supercell g2. Dissolved Air Floatation. Krofta Industry. Krofta TextileIndustry. Kroftaengineering Industry. Kroftaengineering of Textile. Kroftaengineering TextileIndustry. Kroftaengineering Textile Industry. Images (6) Images. Food Processing. Future of the food industry.

Food industry in vietnam. Images 4. Vietnam Food and Textile industry. Vietnam is a leading producer and exporter of a spread of agricultural products including rice, fruits and vegetables, catfish, cashews, coffee, pepper. in the meantime, the country imports great amount of agricultural and food products to satisfy growing demand for both human and animal consumption.

Vietnam has become a food processing hub meeting the high demand for processed food both for international and native markets. The canned Seafood and agriculture products which shipped overseas dominate the industry. The food processing sector contributes 15% of the GDP and accounts for 40% of Vietnam’s export. Till 2025 Vietnam has decided to follow strategy to prioritize food processing sector for economic development. The role of Krofta Engineering in Food industry For Vietnam Economy . The size of Food industry is anticipated to succeed in USD 65.03 billion by 2024 growing at a CAGR of 13.05% during the forecast period (2019 - 2024). Oil extraction machine and Suppliers. Krofta engineering, is a leading manufacturer of world largest supplier of oil extraction machine and deal in good prices in India.

Exports a wide range of products oil mill machinery, Refinery Plant, and Solvent Plant in India. With the team of experienced employee, and skilled labour, we make sure to offer better quality products at most competitive price in least time. At Krofta, we make various kind of oil mills like cold press oil extraction machine, circulatory oil extraction machine and so on. Krofta Oil Extraction machines can extract all kind of oil seeds like cooking oil, Sesame Oil, Coconut Oil, Mustard Oil etc. Our products are widely admired due to their longer service life, top performance and low prices.

Vietnam Food and Textile industry. Automobile workshop tools equipment. Carbon Black Processing Plant. Carbon black is an anhistic type of carbon, the black powder are in light and soft.

It is generating from organism that decomposed after suffering from high temperature according to condition of deficiency of air. Carbon black is basically used as actuate agent and extender of rubber. We are manufacturer and supplier of paint making machine (knitter machine, printing painting machine, , serous lifting and so on) and manufacturing many carbon black production equipment such as- micron muller, magnetic separator, dry (wet) granulator, rotary dryer, fuel preheater etc.

Along with that Krofta are manufacturer of paint production line equipment such as stone paint mixing, water based latex, automatic paint spray, and paint dispersion vacuum tank and so on. Our company is recognized among the most well-known starch processing equipment (flash, spiral flash, paddle dryer and cooler,) suppliers in India.

Our First-rate Service. Oil extraction machine and Suppliers. Specialized-waste-water-treatment-plant. Waste water Equipment. Textile Industry in Bangladesh. Desalination of sea water. Desalination embroil eliminating dissolved minerals from sea water and saline water (a mix of fresh water and marine water) and is gradually vital spring of fresh water.

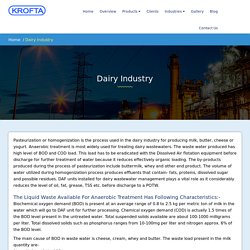

Krofta Engineering Ltd designs pre-treatment sea water desalination units for effective and competent desalination. DAF seawater pre-treatments a gravity focused solids liquid separation procedure. DAF is a developing procedure for the clarification of seawater prior to desalination by reverse osmosis. Krofta Engineering. Pasteurization or homogenization is the process used in the dairy industry for producing milk, butter, cheese or yogurt.

Anaerobic treatment is most widely used for treating dairy wastewaters. Chemical Industry Parameters. Industrial waste waters commonly comprise organic and inorganic matter in fluctuating degrees of concentration.

They may comprise of toxic and other harmful supplies as well as elements that are non-biodegradable or that can decrease the effectiveness of many waste water treatment procedures. Thus, treatment of industrial wastewaters usually is a very challenging task - far more complex than municipal wastewater treatment. DAF is used extensively in the following industries-Meat, poultry, fish processing, Pulp and paper, Dairy industry, Food and beverage and Petrochemicals. Carbon Black Industry.

DAF water treatment plants are intended to eliminate SS (suspended solids), BOD (bio-chemical oxygen demand), oils and greases from a wastewater stream.

Impurities are eradicated through the usage of a dissolved air in water solution manufactured by inserting air under pressure into a re-cycle stream of clarified DAF effluent. DAF delivers the desirable energy for effective flotation in the form of exceptionally fine air bubbles which come to be attached to the suspended solids to be eliminated.

The magnetism between the air bubbles and suspended particles is the outcome of adsorption forces that are functional characteristics of the suspended particle surface, or physical entangling in the particle. This attachment of bubbles to the suspended particles decreases the density of the suspended particle causing in amplified buoyancy, thus achieving effective flotation. Our Major Clients are Pulp & paper industry. Clients Site Map contact us Copyright © Krofta Engineering Limited.

All Rights Reserved. | Developed & Promoted By EdgesOf Solutions Pvt Ltd. Leading manufacturer and supplier of water treatment plants India. Pressure Filter is a closed cylindrical vessel either vertical or horizontal (mostly vertical) containing the filter media over a collector system.

Water flows from top downwards percolating through the media and is drawn off through the collector system at the bottom. Cycle of operation include back washing with or without air scouring, short rinse to waste and return to operation. The filter will effectively give clarified water having suspended solids to less then 20 ppm. The filter will have to be washed with Clarified water periodically. Advantages Vertical / Horizontal Designs ,Strainer/Header-Lateral Collection Systems. Oil Water Separators for Wastewater Treatment-kroftaengineering. We have made a technical collaboration with Stetfield Separators Limited,UK for their Oil Water Seperator like CPI & TPI to market their equipments in across the globe.

Belt Filter Press Systems. Minicell-Dissolved Air Flotation Clarifier. The clarifier has a special drive unit which is fitted to the shaft or cage. This cage or shaft can be provided with an overload sensor, if required by the client. By means of the shaft or cage, scraper arms with scraper blades are connected to the drive unit. Main Advantages:- Very Competitive price simple operation Excellent Performance with "difficult" and "fragile" sludge quality. Three different tank heightts avilable(choice according to the application) The tank and the construction of the minicell can be adapted to the application and to the the effluent.

Download Detail about Minicell The clarifier has a special drive unit which is fitted to the shaft or cage. Supercell - Dissolved Air Flotation. The most up-to-date clarifier based on this principle has been successfully used since 1973 for fibre recovery in paper mills and for a variety of solid / liquid separation processes. Worldwide Installation of more than 3,500 supercells and installation of over 300 units in India alone, speak for the reliance placed by reputed industries and municipalities on the efficiency of Krofta equipment.

The Concept of dissolved air floatation for removing solids from liquids was perfected by Dr. Milos Krofta of U.S.A. DAF technology provide the concepts of supercell methods used for wastewater streams in process the property with different various characteristics, the Krofta engineering offers the supracell concepts for clarification, thicker sludge consistency and low retention. Sedicell-Dissolved Air Flotation Clarifier. Sedicell is a mechanically simple and robust Dissolved Air Floatation clarifier which allows simultaneous removal of floatable and settable solids from suspensions in water for high clarity. Firstly, the raw water enters the central distributor and blends with air released from air carrier water. After this, the air bubbles carry the flocculated solids to the water surface and the Heavier particles settle at the bottom of the tank floor.

After the separation of these particles, clear water present between the zones of floated and settled solid particles, is subsequently discharged into the overflow of an adjustable weir. Performance HIGH CLARIFICATION and reduction of filterable suspended solids are obtained to meet Pollution Control Authority requirements. Download Detail about Sedicell. Dissolved Air flotation India. Advanced DAF system Technique. Krofta clarifiers have retention times as low as 3 minutes and with a possibility of resource recovery in some cases as opposed to the sedimentation methods characterised by very long retention times.

Krofta, is the world leader in this field having more than 1200 installations running successfully all over the world. The advanced DAF system offered by Krofta does not warrant a separate flocculation tank, flocculation mixer, flash tank and flash mixer. The Air Saturation Tank of yesteryears is replaced by the patented Krofta Air Dissolving Tube (ADT) which provides effluent saturated with air in residence time of 10 seconds. Air requirement is also very low as compared to the DAFs of earlier designs. Salient features / benefits of Krofta DAF clarifiers are: Total steel fabrication and negligible civil work facilitating relocation, if needed. Krofta Engineering Limited–India’s No 1 Leading Technology DAF. Carbon Black Industry. Krofta Engineering — Food industry first aid kit and safety tips. Krofta Engineering — Food processing industries in Vietnam.

Krofta Engineering — what is the size of the food industry? Carbon Black Processing Plant. Minicell-Dissolved Air Flotation Clarifier. Belt Filter Press Systems. Oil extraction machine and Suppliers. Sea food Waste Water Treatment. Leading manufacturer and supplier of water treatment plants India. Automobile workshop tools equipment. Krofta Engineering Limited–India’s No 1 Leading Technology DAF. Desalination of sea water.

Tannery and sludge Industry. Tannery industry requires efficient DAF sludge handling system for its animal fat waste products. DAF technology is widely used in animal/food processing/meat/slaughtering applications to eliminate SS (suspended solids), fats, grease and oils from various samples of wastewaters. The elevated rates of processing, lesser footprints and suppleness in procedure has been always appreciated and has taken advantage of these applications. The DAF technology utilizes air to generate micro bubbles which helps in attaching the solids to float onto the surface to be thrown away. Dissolved Air Flotation is principally for solid to liquid or liquid to liquid separation.

Large amount of micro bubbles produced by dissolving and discharging system stick to solid or liquid units with same density as tannery waste water to make the entire sludge float to the surface thus attaining the purpose of solid to liquid or liquid to liquid separation. Advanced DAF system Technique. Krofta Engineering — Important Fact of Automotive workshop equipment... Krofta Engineering — Features of Textile Industry in Bangladesh. Krofta Engineering: Growth of Dairy equipment manufacturing companies. Krofta Engineering provides all types structures, Supply, Installation and dispatching of import making ready equipment's, that address the difficulty of farm and completely different enterprises.

The distinctive scope of import things offered by U.S.A. incorporates milk process Equipment's, oleomargarine milters, unfold softening plants, oleomargarine decays, response pots, clarified butter plants, clarified butter storage tanks, yoghurt tanks, unfold creating, steam heaters. Inward shell of ss 304, protection a hundred millimeter the of thermocole. External protection of ss 304 Standard Features: *All controls vital for operating the tank area unit contained within the nook level pitched base development with its system of supporting welded to base. Supercell - Dissolved Air Flotation. Oil Water Separators for Wastewater Treatment-kroftaengineering. Paint Making Machine. A wide range of raw materials are used in paint industry such as- resins, solvents, pigments, drying oil and extenders. Belt Filter Press Systems.

Oil extraction machine and Suppliers. Krofta Engineering. Sea food Waste Water Treatment. Leading manufacturer and supplier of water treatment plants India. Krofta Engineering. Krofta Engineering Limited–India’s No 1 Leading Technology DAF. Desalination of sea water. Tannery and sludge Industry. Advanced DAF system Technique. Kroftaengineering of textile equipment manufacturers. Kroftaengineering textile industry in bangladesh list. Kroftaengineering bangladesh textile industry.

Kroftaengineering textile industry in bangladesh. Paper industry equipment suppliers. Carbon black. Sludge dewatering.