Super cell. Krofta Engineering — How To Choose The Authentic Paper Factory... Carbon Black Processing Plant. Carbon black is an anhistic type of carbon, the black powder are in light and soft.

It is generating from organism that decomposed after suffering from high temperature according to condition of deficiency of air. Carbon black is basically used as actuate agent and extender of rubber. We are manufacturer and supplier of paint making machine (knitter machine, printing painting machine, , serous lifting and so on) and manufacturing many carbon black production equipment such as- micron muller, magnetic separator, dry (wet) granulator, rotary dryer, fuel preheater etc.

Along with that Krofta are manufacturer of paint production line equipment such as stone paint mixing, water based latex, automatic paint spray, and paint dispersion vacuum tank and so on. Our company is recognized among the most well-known starch processing equipment (flash, spiral flash, paddle dryer and cooler,) suppliers in India. Oil extraction machine and Suppliers. Krofta engineering, is a leading manufacturer of world largest supplier of oil extraction machine and deal in good prices in India.

Exports a wide range of products oil mill machinery, Refinery Plant, and Solvent Plant in India. With the team of experienced employee, and skilled labour, we make sure to offer better quality products at most competitive price in least time. At Krofta, we make various kind of oil mills like cold press oil extraction machine, circulatory oil extraction machine and so on. Krofta Oil Extraction machines can extract all kind of oil seeds like cooking oil, Sesame Oil, Coconut Oil, Mustard Oil etc. Our products are widely admired due to their longer service life, top performance and low prices.

We have a spacious network of clients that hold their faith in us and build an association with us. Krofta are capable to develop the quality and rate of production by using advance technology. Specialized-waste-water-treatment-plant. Waste water Equipment. Textile Industry in Bangladesh. Vietnam Food and Textile industry. Vietnam is a leading producer and exporter of a spread of agricultural products including rice, fruits and vegetables, catfish, cashews, coffee, pepper. in the meantime, the country imports great amount of agricultural and food products to satisfy growing demand for both human and animal consumption.

Vietnam has become a food processing hub meeting the high demand for processed food both for international and native markets. The canned Seafood and agriculture products which shipped overseas dominate the industry. The food processing sector contributes 15% of the GDP and accounts for 40% of Vietnam’s export. Till 2025 Vietnam has decided to follow strategy to prioritize food processing sector for economic development. The role of Krofta Engineering in Food industry For Vietnam Economy . The size of Food industry is anticipated to succeed in USD 65.03 billion by 2024 growing at a CAGR of 13.05% during the forecast period (2019 - 2024). Activated Carbon Filter. Paper factory. Oil extraction machine manufacturers.

Textile Industry in Bangladesh. Waste water Equipment. Specialized-waste-water-treatment-plant. Oil extraction machine and Suppliers. Carbon Black Processing Plant. Automobile workshop tools equipment. Tannery and sludge Industry. Tannery industry requires efficient DAF sludge handling system for its animal fat waste products.

DAF technology is widely used in animal/food processing/meat/slaughtering applications to eliminate SS (suspended solids), fats, grease and oils from various samples of wastewaters. The elevated rates of processing, lesser footprints and suppleness in procedure has been always appreciated and has taken advantage of these applications. The DAF technology utilizes air to generate micro bubbles which helps in attaching the solids to float onto the surface to be thrown away. Dissolved Air Flotation is principally for solid to liquid or liquid to liquid separation. Large amount of micro bubbles produced by dissolving and discharging system stick to solid or liquid units with same density as tannery waste water to make the entire sludge float to the surface thus attaining the purpose of solid to liquid or liquid to liquid separation.

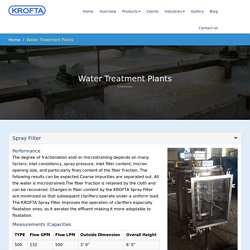

Textile Industry in Bangladesh. Waste water Equipment. Specialized-waste-water-treatment-plant. Oil extraction machine and Suppliers. Carbon Black Processing Plant. Automobile workshop tools equipment. Sea food Waste Water Treatment. Leading manufacturer and supplier of water treatment plants India. Pressure Filter is a closed cylindrical vessel either vertical or horizontal (mostly vertical) containing the filter media over a collector system.

Water flows from top downwards percolating through the media and is drawn off through the collector system at the bottom. Cycle of operation include back washing with or without air scouring, short rinse to waste and return to operation. The filter will effectively give clarified water having suspended solids to less then 20 ppm. The filter will have to be washed with Clarified water periodically. Advantages Vertical / Horizontal Designs ,Strainer/Header-Lateral Collection Systems. Applications. Krofta Engineering. Krofta Engineering Limited–India’s No 1 Leading Technology DAF. Desalination of sea water. Desalination embroil eliminating dissolved minerals from sea water and saline water (a mix of fresh water and marine water) and is gradually vital spring of fresh water.

Krofta Engineering Ltd designs pre-treatment sea water desalination units for effective and competent desalination. DAF seawater pre-treatments a gravity focused solids liquid separation procedure. DAF is a developing procedure for the clarification of seawater prior to desalination by reverse osmosis. The success of DAF relies on the measure of bubbles and particles moving through water, and to the dissolution and precipitation of air. The performances of the DAF system will be inspected by measuring: -Turbidity, suspended solids, TOC, and pH Seawater is the most lavish source on the earth.

Sea DAF is a dissolved air flotation machine with a high transmission rate. Tannery and sludge Industry. Advanced DAF system Technique. Krofta clarifiers have retention times as low as 3 minutes and with a possibility of resource recovery in some cases as opposed to the sedimentation methods characterised by very long retention times.

Krofta, is the world leader in this field having more than 1200 installations running successfully all over the world. The advanced DAF system offered by Krofta does not warrant a separate flocculation tank, flocculation mixer, flash tank and flash mixer. The Air Saturation Tank of yesteryears is replaced by the patented Krofta Air Dissolving Tube (ADT) which provides effluent saturated with air in residence time of 10 seconds. Air requirement is also very low as compared to the DAFs of earlier designs. Automobile workshop tools equipment.