AutoCAD Tip: Using the BOUNDARY Command (Between the Lines) MakiBox A6 - The $300 Desktop 3D Printer - Makible. The Open Kinect project – THE OK PRIZE – get $3,000 bounty for Kinect for Xbox 360 open source drivers. November 4, 2010 AT 3:40 pm Hi from team Adafruit, we’re going to do our first ever “X prize” type project.

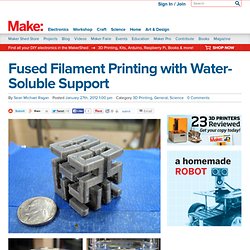

Hack the Kinect for Xbox 360 and claim the $2,000 bounty! NOW $3,000 What is Kinect? Kinect for Xbox 360, or simply Kinect (originally known by the code name Project Natal (pronounced /nəˈtɒl/ nə-tahl)), is a “controller-free gaming and entertainment experience” by Microsoft for the Xbox 360 video game platform, and may later be supported by PCs via Windows 8. What is the hardware? The Kinect sensor is a horizontal bar connected to a small base with a motorized pivot, and is designed to be positioned lengthwise below the video display. Fused Filament Printing with Water-Soluble Support. Veteran Thingiverse user Tony Buser has printed a model (intended to be an approximation of the fractal Hilbert curve) using polyvinyl alcohol (PVA) as a support material.

Once everything is printed and cooled, the PVA is dissolved away in a glass of water, leaving only the polylactic acid (PLA) model. This technique, when perfected, should allow RepRap-style FFF printers to produce objects with overhanging parts that are currently very difficult, or impossible, for them to print. Tubular Drive by rweaving.

Put a bird on it art set by Noesis. Best Blogs. It’s time to start 3D scanning the world. MakerBot's 3-D Printers Let Consumers Dream Up Prototypes Of Pretty Much Anything. But Do We Need More Plastic? A 2D Tour of a 3D Printer Factory. It's only coincidence, but even as simulating 3D stereoscopically has gotten more and more popular in movies, TVs, and home theater projectors, a completely different type of 3D—the kind that deals with real-world, 3D objects—has also become a hot new area for printers.

And because it's so new, when I started talking to Buildatron Systems about reviewing one of its 3D printers (stay tuned for that story), I also asked if I could tour its ... ummm ... manufacturing facilities. That's a decidedly grandiose description for the few-hundred square foot office space where Buildatron puts its printers together.

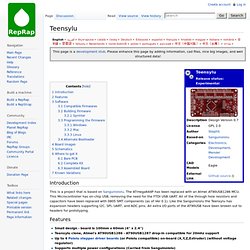

But the space is probably no smaller than the garage that the two Steves—Wozniack and Jobs—started with. The comparison to Apple's—and, more broadly, the personal computer's—early days is hard to avoid. In fact, the parallels are striking. The current state of the industry shows in our photos if you know what to look for. Not so incidentally, Buildatron is part of the RepRap community. Printrbot - Home. A Christmas Calendar Filled With 3-D Printed Chocolates. Forget about wasting your money this holiday season on some crappy advent calendar full of crappy chocolate done up in crappy Christmas iconography.

(Who wants to eat Santa’s face on Christmas Eve? That’s just weird.) Now, thanks to rapid-prototyping technology, you can customize your own advent calendar, then print out the chocolates on demand. At least that’s what the clever folks over at Moving Brands, a London-based design studio, have done. Each day of the month leading up to December 24, a different employee designs and prints a unique three-dimensional chocolate using the office’s hot new toy, a RepRap rapid prototyping machine. Moving Brands boasts that what it has created are “the world’s highest resolution 3D printed chocolates.” [Images courtesy of Motion Brands] MetaRepRap Soup. Pippilotta had this cool idea of melting a printed star onto hot stones and o... - MetaRepRap Soup. NextEngine 3D Laser Scanner. 3D printing: Difference Engine: Making it. Best Blogs. MakerGear Prusa Mendel RepRap (In Progress) How to Use ReplicatorG - ReplicatorG.

Start ReplicatorG First, start ReplicatorG!

Configuring your machine If it's your first time using ReplicatorG, you'll need to configure it to connect to your machine. Select "Machine Type (Driver) from the Machine menu. Select the entry that best describes your machine. If (like most users) you're connecting to your machine via a serial port (like a USB-TTL cable), you'll need to tell ReplicatorG which serial port to use. The naming of serial ports varies from platform to platform, so it may not be obvious which one to select at first. Once you've selected a port, click the connect button at the right of the top bar and ReplicatorG will attempt to connect to the machine. Take a look at the row of buttons at the top of the ReplicatorG window. The Build from SD button, just to the right, will pull up a list of the files currently on the SD card in your machine and will allow you to print one of them. Printing from an STL file. Teensylu. This page is a development stub.

Please enhance this page by adding information, cad files, nice big images, and well structured data! Teensylu Release status: Experimental Introduction. Printrbot: Your First 3D Printer by Brook Drumm. I designed the Printrbot to be the simplest 3D printer yet.

There are some great kits out there - the Makerbot, the Ultimaker, the Prusa Mendel, and others - but none as small and simple as the Printrbot. This all-in-one 3D printer kit can be assembled and printing in a couple of hours. Other kits will not only take you many more hours to build, they will also have hundreds more parts, and they will cost more. My design also does away with the finicky calibration and adjustment from which most 3D printers suffer. This is the printer a kid could put together. Uld 3D printing end our throwaway culture? There's a tiny knob missing from my hands-free car kit, which I keep meaning to replace.

The thing is, I don't think I can buy parts for it, so I probably need to fork out for a whole new system, which, frankly, I'm reluctant to do. Sound familiar? Build a Laser 3D Printer - Stereolithography at Home. Here is how to make a Stereolithography 3D Printer. HOWTO make your own 3D printer. Digital Manufacturing Report: 3D Printing and RepRap On the March. At England’s University of Bath Digital Manufacturing Lab, they love their RepRaps, which may be multiplying like lemmings.

That madcap bunch of 3D printer aficionados at the University of Bath, England is at it again. Now they have opened the Digital Manufacturing Lab to showcase the capabilities of RepRap, the 3D printer that can reproduce itself. The RepRap Saga Part 14: Lessons Learned - NBitWonder. Nanopositioning Stages, Systems. 3dp Blogs. HeatSync Labs. Discover Projects » Technology. MakerSlide Open Source Linear Bearing System by Barton Dring.

Sorry about the lame video.

I am not very good at that kind of thing, but I am good at designing and building CNC and digital fabrication equipment. CAD Software. Autodesk @ 3D. Create 3D models from photos. DIY CNC. 3D Printing Services. RepRap. RepRap is humanity's first general-purpose self-replicating manufacturing machine. RepRap takes the form of a free desktop 3D printer capable of printing plastic objects. Since many parts of RepRap are made from plastic and RepRap prints those parts, RepRap self-replicates by making a kit of itself - a kit that anyone can assemble given time and materials.