Unimat Lathe and Micro Milling machine rebuilds. I wasn't sure where to post this, so here it is.

I recently acquired a Unimat to replace the one I let get away several decades ago. It was so much fun I decided to get another. So, one will be a dedicated Micro Mill and one will be a lathe. The mill will be a stand alone unit, and also be able to reach the carriage on the lathe for more versatility. The first machine I got is one of the Zamak casting units. Boring Small Holes 3. Bars with HSS Tips.

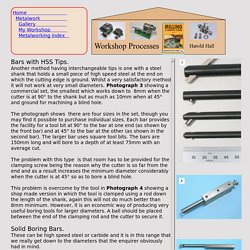

Another method having interchangeable tips is one with a steel shank that holds a small piece of high speed steel at the end on which the cutting edge is ground. Whilst a very satisfactory method it will not work at very small diameters. Photograph 3 showing a commercial set, the smallest which works down to 8mm when the cutter is at 90° to the shank but as much as 10mm when at 45° and ground for machining a blind hole. The photograph shows there are four sizes in the set, though you may find it possible to purchase individual sizes. Paul's Fantastic Workbench!: A dividing head for the Unimat. Another usefull accessory, indexing tables or dividing heads are used when milling or drilling.

They can be used when cutting gears, cutting keyways in cylindrical work or drilling holes in a circular pattern, think bicycle hub. Another use is to mill work square, rectangular etc. Wiki explains it better! EmcoUnimatDH.pdf.

Climb Milling vs Conventional Milling. AC Motor Speed Controller. Reliable and simple to install project that allows you adjust the speed of a 230Vac 50Hz mains powered electric drill or single phase brushed "universal" AC motors rated up to 600 Watts maximum.

Simply turn the potentiometer to adjust the motors RPM. Uses a proven diac/triac based circuit. Onboard safety fuse. Heatsink included. Please note that some loss of power occurs at low RPMs. PRODUCT SELECTION NOTES: The motor controller should have an output load capacity at least 25% above the motors peak power requirement. 4 Jaw Independent Lathe Chucks. Unimat. Unimat Instructions Page1_20s. Unimat Instructions Page21_40s. Emco Lathe Users Page. Groups. Yahoo "UNIMAT" Group A friendly group for any one interested in the Unimat lathe/milling machine.

The forum's goal is to exchange information about, promote the use of and gather historical information about these amazing little machines and their accessories. Membership... All memberships to this group are automatically approved and allow immediate use of it's content. However... And... Unimat3 Owners Welcome But Please Use The “UNIMAT3” Group For Questions Or Disscussions Directly Related To “UNIMAT3” Lathes. Please Remember... Emco Unimat SL - The personal website of Dirk E. Fassbender. Multitorno ROWIC. Mini Lathe Links. Gearcutting. Motortips. Very early Unimat DB with brushless induction motor Pix credit, Tony Griffiths A new page to consolidate the growing volume of motor information Motor Section Moved from Tech Tips Page I have had a lot of emails requesting info on servicing of motors.

This should help. This section updated November 2010. Home Wiring Guide - Residual Current devices. A residual current device (RCD), or residual current circuit breaker (RCCB), is an electrical wiring device that disconnects a circuit whenever it detects that the electric current is not balanced between the phase ("hot") conductor and the neutral conductor.

Such an imbalance is sometimes caused by current leakage through the body of a person who is grounded and accidentally touching the energized part of the circuit. A lethal shock can result from these conditions; RCDs are designed to disconnect quickly enough to mitigate the harm caused by such shocks. How a rack cutter can produce gear teeth. Proper hobbing generates the involute gear shape essentially by putting the proto gear through every possible permutation of positions against a rack shaped cutter and cutting away all the bits that interfere.

The result is a perfect involute. For a lot of practical applications, we can use approximations to the involute and not notice much difference. Single point cutters may use circular arcs for example. How a rack cutter can produce gear teeth. Cutting gears with a simple hob.

The 2mm Scale Association. Unimat SL Lathe Compatible Accessories. A2Z Corp E-Commerce Store. Basic Lathe Tool Grinding. Mini Lathe Tool Grinding. Tool grinding is part science and part art, but can be an enjoyable side activity to working with the lathe.

My goal here is to teach beginners enough to get them started with a few basic tools. Here are some additional resources: You can, of course, buy ready-made carbide-tipped cutting tools. If good quality, these work well and last a long time. The real advantage to grinding your own tools is not cost savings, but having the ability to make a tool for whatever purpose you may run across in your work. RS, RT, VS belting, conveyor belting, driving belting. The Taig Lathe and Milling Machine. Elmer’s ‘Wobbler’ #25 « Start Model Engineering. Elmer's 'Wobbler' #25 The perfect choice for your first engine The choice of your first engine build project is critical and should follow the ‘KISS’ principle.

Keep It Simple and Straightforward! Handgewindeb satz m12x1, 2tlg hss feingewinde. Miniature Machining Techniques. The Book of the Unimat. Turning Information Center. Welcome to Michigan Technological University's Turning Information Center!!

We hope to educate and inform the public about current technology and research relating to Turning. Below are the areas that we currently have on the net. Southern Belting Ltd Sothane Page. Transmissions - Pulleys & Belts UNIMAT : Mailing list for people interested in the EMCO UNIMAT Machine. Advanced Tool Sharpening. Many people create HSS lathe tools using nothing more than a bench grinder and get perfectly acceptable, if not downright excellent, results.

For most normal sized projects with moderate tolerances that may be all you'll ever need. Locomotive Steam Fittings & Drawing. {*style:<i>RING 01327 878988 FOR </i>*} {*style:<i>STEAM FITTINGS </i>*}