Untitled. Tataki: Japanese Traditional Earthen Floor - The Last Straw Journal. By Kyle Holzhueter Traditional Japanese earthen floors are called Tataki.

The pronunciation is similar to the Japanese verb to pound, tataku, as these floors are pounded similar to traditional earthen floors in many other countries throughout the world. However, the word Tataki is written in Chinese characters as 三和土, meaning literally “three and earth” or “three harmony earth”, which reflects the fact that Japanese Tataki floors consist of three ingredients, earth, lime and bittern, a byprod the creation of a traditional earthen floor in Northern Japan as conducted by Keisuke Noda-san of Noda Plaster Works. Completed Floor Gravel Layer The floor is completed in stages. Ink lines are snap to identify layers and the finish height. The earthen floor is 100mm thick and consists of three layers. In Japan, the dimensions, techniques and tools used vary by region. The Mix As mentioned above, Tataki consists of three ingredients: earth, lime and bittern.

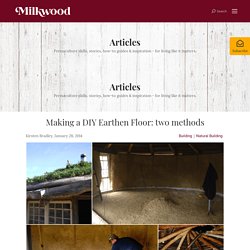

Sandy soil 100g Hydrated lime 10g Bittern 1g. Making a DIY Earthen Floor: two methods. After completing the strawbale walls and the roundwood, reciprocal roof of the Milkwood Roundhouse, we wanted a gorgeous floor to complete this hand-crafted natural building.

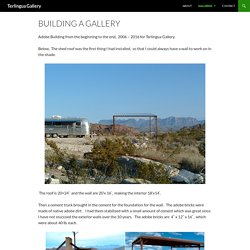

So an earthen floor was a natural choice. There’s not much easily accessible info out there on how to make your own earth floor, however. So we’d like to share what we learned with you… Building a Gallery. Adobe Building from the beginning to the end, 2006 – 2016 for Terlingua Gallery.

Below, The shed roof was the first thing I had installed, so that I could always have a wall to work on in the shade. The roof is 20×24′ and the wall are 20’x 16′, making the interior 18’x14′. Then a cement truck brought in the cement for the foundation for the wall. The adobe bricks were made of native adobe dirt. I had them stabilized with a small amount of cement which was great since I have not stuccoed the exterior walls over the 10 years. Although it took a period of 10 years to complete, it could have been done in 3 years or less if I could have dedicated full time to its completion. In January 2006 the foundation for the walls was poured and soon after I had the adobe bricks made at Fulcher Ranch. I had the bricks made from dirt at Fulcher Ranch which is on Terlingua Creek. In the beginning, I had 2000 blocks made. Adobe dirt straight from the ground 8 shovels sand 1 shovel cement 1 shovel.

Earthen Floors: A Quick Introduction. Earthen floors are floors composed of compacted clay, sand, and straw.

They are made flat and troweled smooth just like a concrete slab. However, the finished product is much softer on your feet… and on the earth itself. You can build an earthen floor with readily available materials. The labor input is quite high, but the material cost should be very low. And of course, the embodied energy is low, too — this is a very resilient, low tech method that can be incorporated in a variety of locales. Where can I install an earthen floor? Earthen floors can be installed in new construction, either over a compacted gravel subfloor or even a concrete slab. What are earthen floors made of? Earthen floors are made of clay subsoil, sand, and straw in varying proportions.

If you’re building an earthen floor base layer, you can use less fine material and lots and lots of straw in varying lengths. Are earthen floors durable? Can earthen floors be easily cleaned? Ok, what are some other benefits? Adobe Floor Basics - How to build a dirt cheap floor. Seems crazy, right?

A dirt floor, of all things! Well, time for a perception shift... Adobe floors are lusciously beautiful and quite durable. And best of all, in most regions they can be made from local clay soil. (Which makes them dirt cheap...sorry, couldn't resist.) The Concept An adobe floor, or earthen floor, relies on the sticky binding properties of clay...one of the most versatile building materials I know of. What I describe below is the method I use to install an adobe floor.

The Layers A typical adobe floor includes a build-up of layers, each with a purpose. . #1: The substrate You want your floor to rest on solid ground (or a stiff framed floor with little flex) . #2: The capillary break Next you install several inches of gravel to provide a capillary break that prevents any potential liquid water in the ground from rising up into the floor.

. #3: The vapor barrier Next you lay a vapor barrier that covers the entire floor area. . #5: The base layer.