Benchcrafted Split-Top Roubo Bench Build - talkFestool. Split Top Roubo. MeshCAM for Mac/OSX. From SketchUp to CNC Fabrication. This video series shows how to get from CAD, to CAM, to a CNC fabricated product.

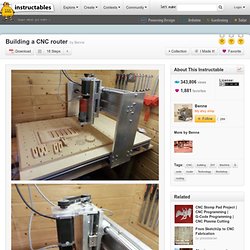

The tools we will be using are SketchUp for CAD, CamBam for CAM, Mach3 for gcode reading/CNC control, and a CNC router (greenBull from BuildYourCNC.com) for part fabrication. Keep in mind during this tutorial that the particular hardware/software tools, materials and application of these instructions will vary from person-to-person, region-to-region, and project-to-project. You may be using a different CAD program, CAM program, CNC control program, CNC machine, material sizes and fastening methods, and you will likely be fabricating a wide variety of products in the end. So, keep in mind that this tutorial is one of many different ways of going from CAD to final product. In this example, we will be fabricating a cart for our blackTooth laser cutter ( This cart will allow us to store materials and easily move the machine from place to place. Here is the link to download the plugin: Building a CNC router. This instructable will show you how I built my CNC router.

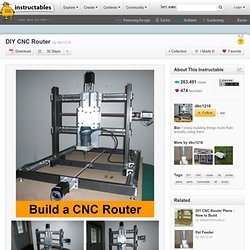

I hope you can draw some inspiration from my build and that this instructable will be helpful for your future projects. This instructable shows all the steps I went through in designing and building this CNC router. The main thing I like about a CNC router, is that it is so versatile. Building your own CNC router/milling machine. Already at the age of 12 I was dreaming of making a machine which could make things!

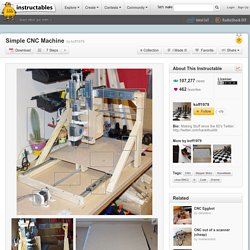

A machine which would give me the opportunity to create products for in and around the house. TheMaker2 Homemade CNC. Simple CNC Machine. What I'm going to try and show you in this instructable is how to build a simple CNC machine.

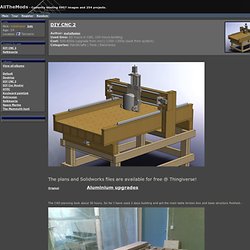

Now when I say Simple I mean you only require basic tools & materials to build the machine. The machine is made out of Sawn Timber, drawer sliders, nema 17 Stepper motors, a TB6560 Driver Controller Board and a Dremel Trio as the milling/cutting tool I started about year ago trying to build a CNC machine, I tried a few different designs but i struggled to get the building of them right. This was mainly down to the complexity of some of the designs and the lack of equipment I needed to build them and the money that they cost. So I went back to the drawing board and tried to build a machine that was easy to make and used readily available parts to keep the price down. The Video Gives a quick overview of the Machine. Building your own CNC router/milling machine. Description du projet. 3 axis CNC router MDF ( metric ) by Metalfusion. Hardware Modding & Tuning Gallery. The plans and Solidworks files are available for free @ Thingiverse!

Original Aluminium upgrades The CAD planning took about 30 hours. So far I have used 2 days building and got the main table torsion box and base structure finished.- I was able to finish the torsion box in a day, took about 10 hours total. Second day I had lots of other stuff to do besides this,- but managed to build the base structure. Some of the plans I made with solidworks, they will be available for free later on. This is the current situation, it was quite hard to maneuver these big objects in such a cramped space. The project will move much slower from now on as I can only work on it at weekends. Kits & Plans. "Joe's CNC 4x4 Hybrid" (LeadScrew Version) Email for Price: joecnc2006@yahoo.com The "Joe's CNC 4x4 Hybrid Kit" does not include Plans or access to the Support forum and contains only the MDF and HDPE items shown.

"Joe's CNC 4x4 Hybrid" Rack and Pinion (Most Popular Version) $325.00 plus $35.00 shipping and handling in the US Only. The Largest Forums for CNC Professional and Hobbyist alike! Fr.accuride-europe.com/installations/2601.pdf. Sélecteur de glissières en stock - Accuride. Quincaillerie Qama - Amortisseurs de tiroir. Coulisse et glissière de tiroir de cuisine et de bureau. DIY: Réalisation d'un séparateur cyclonique (cyclone dust separator) pour aspirateur d'atelier et CNC. L'usinage à commande numérique, c'est bien mais selon les matières usinées, cela peut faire pas mal de déchets et de poussière.

Disposant d'un aspirateur eau et poussières Kascher WD3300, j'ai vite vu que le sac se colmate assez rapidement lors de l'utilisation en environnement CNC, notamment lors de l'aspiration de copeaux de MDF. J'ai donc cherché une solution et trouvé les séparateurs de poussière de type 'cyclone'. Malheureusement, ces solutions sont soit très chères et de grande taille, soit pas disponibles en France. J'ai donc entrepris d'en construire un.. Voyons comment. Démo Pour commencer, une petite vidéo s'impose. La technique : Un article sur Wikipedia France explique très bien la technique de séparation par cyclone: Exemples de réalisations : Pré-Étude Taille du cyclone Ne produisant pas des quantités industrielles de copeaux, nécessitant un grand cyclone comme ceux utilisés dans les ateliers bois (jusqu'à 2 mètres de haut!) Choix des matériaux Étude Plan sous Sketchup.

Homemade CNC Router The Builder's Guide (FREE!) This guide is still under construction!

Sections Introduction My Experience About Kits and Plans About This Guide The Guide Starts Here IntroductionSo you've decided to build a homemade CNC router or maybe youre just considering it, but where do you start? There are many advantages to owning a CNC router. Homemade CNC routers can cut and carve almost anything. For any hobbyist or DIYer, this opens many doors. Yes, you can build a CNC router that is just about as good as any other for a fraction of the retail price, and its not that difficult! There is also a great deal of flexibility when you design and build your own machine. CNC Machine Build. DIY CNC Router. If you have any interest in purchasing a kit version of this machine please click the above button and complete the form so that I can gauge the level of interest.

This instructable will show you how to construct a CNC Router that will allow you to cut 3-D shapes out of wood, plastic and aluminum using a standard hand held router. Recently I have noticed that more and more projects on instructables have involved the use of some sort of CNC machine, be it a laser cutter, 3d printer, milling machine, etc. I wanted to join this revolution of digital fabrication and start making my projects even better using these tools. Tune Your Bandsaw - Woodworking Tools. 6 adjustments deliver professional results.

By Mark Duginske I love bandsaws, even though they have a reputation as troublesome tools. I suppose that’s why I like them, because I enjoy investigating woodworking machinery. I’ve tinkered with dozens of 14-in. bandsaws, trying to understand how they work and how they should be set up.