San Francisco Bay Area | KNITS FOR LIFE New blog series: Meet the Pattern I’m excited to announce my new blog post series, “Meet the Pattern.” This series reveals the stories behind knitting and crochet patterns. “Meet the Pattern” fills the gap in the blogosphere between bland knitting and crochet “pattern round-ups” and “finished object on my oak dinner table” buzz-kills. Each story will differ a little, but the goal is to: introduce you to a new patternshow you what’s involved in making ithear some of the designer’s thoughtsfollow my finished object on its first adventures. Now, with much fanfare, let’s Meet the Pattern! How to Yarn Bomb: Tips & Tricks from a Pro Have you seen trees and statues covered with brightly covered yarn in your neighborhood and wondered how it was done? Or have you seen photos of knitted or crocheted statues online and dreamed of becoming your town’s next yarn bomber? If so, you’ve come to the right place. Here, we’ll reveal how to yarn bomb in five steps. Photo via of Oakland Art Enthusiast What is a yarn bomb? A yarn bomb is form of street art where yarn in any form (knit, crochet, latch hook, cross stitch, amigurumi, or simply wrapped) is attached to an object in the public environment. How to yarn bomb: Step 1: Find the object you would like to yarn bomb. If you plan to knit or crochet a fabric, then choose a 3-D object that you can sew your fabric around, like a tree, street post or statue. When choosing this route, make sure to choose an object that allows you to secure your yarn bomb from falling down. Photo ©Damon Landry/damonabnormal “Park It” by Lorna Watt/KnitsForLife; photo via of Jill Watt You’ll want to bring:

SEWING | ORIGAMI BENTO BAG TUTORIAL - ARIZONA FABRIC TOUR & GIVEAWAY! — VERY SHANNON Ok, you guys. Seriously. About once or twice a year I become obsessed with a fabric line. This year I am head over heels in LOVE with Arizona by April Rhodes for Art Gallery Fabrics Limited Edition line! **This giveaway is now closed. I seriously need a truck load of this line to fill my house with! I ended up first making something that I will be showing you later this month and for the tour today I decided to whip up a fun tutorial for an Origami Bento Bag using only 3 fat quarters! I used the prints Desert Blanket, Tomahawk Stripe and Canyon Wall for my bag. You ready to make one too? *Copyright 2014 VeryShannon.com. // MATERIALS 3 fat quarters of your choice cut to the following: (2) cut to 16.5"W x 17"H and (1) cut to 17"W x 17"H I used Desert Blanket, Tomohawk Stripe and Canyon Wall OR 1 piece of fabric that is 49"W x17"H*Optional: 1 piece of fabric (or leather) 5.5"W x 3.5"H for handle. // HOW TO CUSTOMIZE This bag is easy to make in any size of your liking. That's it!

Twilight Taggers: How To Yarn Bomb I get asked all the time "How do you yarn bomb exactly?" So here's a How To guide on yarn bombing. This is just from my personal experience. Everyone does it differently. Everyone needs to find their own flow. Start with something small like a small pole piece or a granny square and then you'd be done in no time and won't be discouraged with such a large time consuming project. 2. 4. If using only sewing, you run the risk of the piece not staying tied securely to the object. Sewing a tag onto a horizontal object like a banister is fine as it will generally stay well. 8. 9. More helpful links:What You'll Need To Take When Yarn Bombing Things To Remember About Yarn BombingIdeas For Yarn Bombs To Make Luv Bali. P.S. Nicole Mallalieu Design - Tips and Tutorials for Making Bags and Purses Tips & Tutorials Back to top VIDEO TUTORIAL - How to set in eyelets with a setting tool VIDEO TUTORIAL - Simple method for inserting purse feet. VIDEO TUTORIAL - How to Use a Clover Quick Yo Yo Maker This is an absolute must-read for anyone embarking on bag-making! ALWAYS use interfacing on any bag piece where the pattern reads "cut [specified number] i/f". Interfacing creates structure if it is used on the body of the bag - but is entirely optional here, and using it depends on the weight of the fabric and the finished look that you require. By fusing interfacing to every piece of the outside of the bag you'll add a lot more structure and "OOMPH" to the fabric. You can interface the lining if you want a stiff lining, but it shouldn't be the main support in the bag. It's important to remember that by adding an extra layer of interfacing to a bag piece, you are also increasing the bulk of the fabric. Click here to see the range of interfacings at Nicole Mallalieu Design 1. 2. 3. 4. 1. 3.

'Yarn bombing' Polish artist Olek brightens up morning commute by covering TRAIN with crochet Polish artist Olek spent two days covering the locomotive with crochetOlek's work is proving popular with locals in the Polish city of LodzThe artwork, now named Deadly Romance, will be on display until the 19th By Ruth Styles Published: 18:44 GMT, 5 August 2013 | Updated: 18:59 GMT, 5 August 2013 From crocheted boyfriends to woolly teapots, it would seem there's little that can't be created with a pair of knitting needles and a few balls of wool. But one Polish artist has decided to take things a step further and has covered an entire train with colourful crochet. And by covering the full-scale Px48 steam locomotive engine and carriages in crochet, artist Olek - real-name Agata Oleksiak - says she has pulled off her largest 'yarn bombing' to date. Hard work: It took Polish artist Olek two days working round the clock to completely cover this train in yarn Impressed: The crochet-covered train has proved a hit with Lodz locals and will be on display until the 19th 'I had the best crew ever.

You SEW Girl: 'Template Plastic' Bag Base Tutorial As promised, I'll be posting up a heap of tutorials this month, trying to cut down the bandwidth/downloads from my website. I can't promise one EVERY DAY, but I'll definitely try to keep them flowing throughout August. This one is a SUPER EASY way to add a sturdy TEMPLATE PLASTIC base to any two-piece bag with a boxed corner. It'll work an any of my BEGINNERS patterns, as well as the Hobo, Sling, City Bag, Evening Bag, Dress Bag, Beach bag and any pattern that uses a similar base structure. Template plastic is cheap and cheerful, simple to use and creates a resilient, washable base for fabric bags (...and yes, we sell it!!) 1. 2. 3. 4. a)Fold the calico in half, lengthwise, and seam down the long raw edges. b) Clip the corners of the seam allowances 5. 6. 7. You'll see how Sharon has used this tutorial on my Make-Up Purse kit over here...

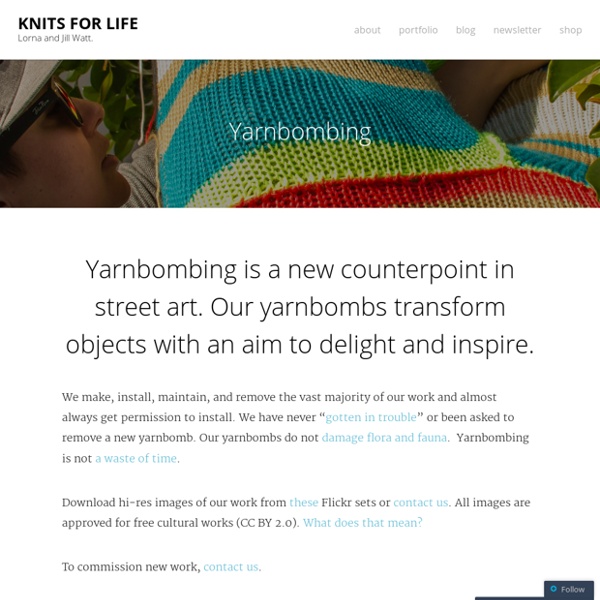

Yarn bombing Type of graffiti or street art Yarn bombing (or yarnbombing) is a type of graffiti or street art that employs colourful displays of knitted or crocheted yarn or fibre rather than paint or chalk. It is also called wool bombing, yarn storming, guerrilla knitting, kniffiti, urban knitting, or graffiti knitting. While other forms of graffiti may be expressive, decorative, territorial, socio-political commentary, advertising or vandalism, yarn bombing was initially almost exclusively about reclaiming and personalizing sterile or cold public places.[1] It has since developed with groups graffiti knitting and crocheting worldwide, each with their own agendas and public graffiti knitting projects being run.[2] The practice is believed to have originated in the U.S. with Texas knitters trying to find a creative way to use their leftover and unfinished knitting projects, but it has since spread worldwide.[6][1][7] Yarn bombing's popularity has spread throughout the world.

Text-Team – Page 12 – Textinfo The production of wool: The word wool is restricted to the description of the curly hairs that form the fleece produced by sheep (Rogers, 2006:931). The sheep’s fleece is removed once a year by power-operated clippers. Newly removed wool is known as raw wool and contains impurities such as sand, dirt, grease and dried sweat. Long wool fibres will be combed and made into worsteds, while short wools are described as carding, or clothing wools. When the wool arrives at the mill it is dirty and contain many impurities that must be removed before processing. The quality and characteristics of the fibre and fabric depend on a number of factors, such as the kind of sheep, its physical condition, the part of the sheep from which the wool is taken, as well as the manufacturing and finishing processes (Corbman, 1983:273). The chemical composition of wool: The cross-linkages in the chains permit the ends to move up and down, which provides the resiliency of the fibre (Labarthe, 1975:51). lustre Care:

Not Your Grandma's Knitting: 20 Incredible Yarn Bombs While certain types of permanent graffiti can be a very beautiful addition to an otherwise bland space, much of the time it's unattractive and a pain to remove. Yarn bombing, however, is a completely different story. Easily removable, yarn bombing focuses less on making a permanent statement and more on lending a sense of warmth to colder spaces. From bike racks to buses, yarn bombers seem to have found a way to add a knit cover to almost any type of outdoor item. Check out 20 of the most impressive, stringy works — they just might inspire you to craft something of your own. Show As Gallery What do you think of this crafty trend? Image: Flickr, waltarrrrr

Plain Weaves, Rib Weave, Matt Weave, Basket Weave, Twill Weave Examples of Fabric: Satin: Used for ribbons, trimmings, dresses, linings etc, and originally was an all silk fabric with a fine rich glossy surface formed in a warp satin weave. The warp is much finer and more closely set than the weft, and the latter which only shows on the under side is frequently composed of cotton. Double faced Satins are made on the reversible warp backed principle, with one side differently colour from the other. 2.5 Jacquard: Jacquard patterns, when carefully analyzed, may be seen to contain combinations of plain, twill, and satin weaves, even in the same crosswise yarn. Method of Construction: Warp is individually controlled with each pick passage creating intricate designs Household Uses: Upholstery, wall hangings Types of Jacquard fabric; Brocade:. 2.6 Leno or Gauze: In leno or gauze weave pairs of warps are twisted over each other with each passing of filling yarn. Household Uses: Thermal Blankets, curtains

5 Most Amazing Yarn Bombings You Don't Want to Miss Nothing brings a smile to my face like a yarn bombing. Whether it’s a huge installation on a bridge or just a small one like a doorknob cozy, seeing everyday objects covered in yarn brightens my day instantly. Fiber artists like Olek and Magda Sayeg are practically yarn craft-household names in the world of yarn bombing, organizing some of the most famous fiber installations we know. Now, yarn bombings are now becoming so large in size that it often takes the cooperation of fiber artists and large organizations to stage the entire installation. Photo via Yarn Bombing Los Angeles Craft and Folk Art Museum, Los Angeles From far away, you’d never know that all these colorful squares are actually crocheted granny squares. More than 500 crafters from around the world contributed to this specific project. Photo via Alicia Kachmar Mr. Yarn bombing statues is not uncommon, as we’ve seen from yarn bombings like the Rocky statue in Philly. The red sweater, symbolic of the sweaters Mr.

Bonding Techniques Used in Making Elastic Nonwoven Composites Introduction This report encompasses some of the most interesting processes of forming composite elastic nonwoven webs. Elasticity is a desired property in nonwoven webs to be used in bandages, diapers for a tight yet comfortable fit, garment linings for a body-hugging fit, bandages that should be stretchable to cover the wound well and several other applications where it may be needed 1). There are multiple processes of making an elastic nonwoven composite. How the two webs are bonded makes the processes different from one another. The Processes: 1. In this process, the product is manufactured by passing a longitudinally oriented nonwoven material over a roller so as to apply an adhesive to one surface of the nonwoven material. Another patent 3) discusses a composite nonwoven elastic web which is composed of a nonwoven elastic web that is joined to a fibrous nonwoven gathered web. 2.

Natural dyeing techniques / Middle - Years 7–10 / Teaching snapshots / Resources / Welcome to Technology Online - Technology Online Faced with teaching Soft Materials in a Hard Materials workroom, Technology teacher Demelza Cusens chose to see it as a challenge rather than problem. "I thought it was a perfect opportunity to change people's perceptions about Soft Materials and so I took it from the textiles manipulation standpoint." Demelza Cusens Timetable changes meant Demelza would only see her Year 9 classes for five one-hour periods over ten days, so she also needed a context that would allow her students to complete their work within this time frame. Selection of dye patterns. Blue fabric dye patterns. Demelza was keen to introduce her students to natural dyeing techniques, having attended a week-long course run by India Flint; see the Technology Online Resource Review on India Flint's book Eco Colour: Botanical dyes for beautiful textiles. They discussed various concepts and decided to construct house roofs, made of fabric, to represent the village. "I thought, we'll experiment and surprise ourselves as we go.