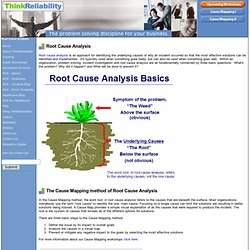

Cause Mapping Basics. Root Cause Analysis Root cause analysis is an approach for identifying the underlying causes of why an incident occurred so that the most effective solutions can be identified and implemented.

It's typically used when something goes badly, but can also be used when something goes well. Within an organization, problem solving, incident investigation and root cause analysis are all fundamentally connected by three basic questions: What's the problem? Why did it happen? And What will be done to prevent it? The Cause Mapping method of Root Cause Analysis In the Cause Mapping method, the word root, in root cause analysis refers to the causes that are beneath the surface. There are three basic steps to the Cause Mapping method: Define the issue by its impact to overall goals Analyze the causes in a visual map Prevent or mitigate any negative impact to the goals by selecting the most effective solutions.

For more information about our Cause Mapping workshops click here. Conseil: 5 WHY. Diagramme de causes et effets. Un article de Wikipédia, l'encyclopédie libre.

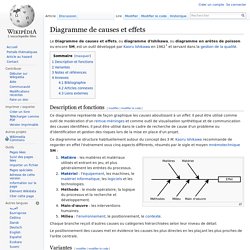

Le Diagramme de causes et effets, ou diagramme d'Ishikawa, ou diagramme en arêtes de poisson ou encore 5M, est un outil développé par Kaoru Ishikawa en 1962[1] et servant dans la gestion de la qualité. Description et fonctions[modifier | modifier le code] Ce diagramme représente de façon graphique les causes aboutissant à un effet. Il peut être utilisé comme outil de modération d'un remue-méninges et comme outil de visualisation synthétique et de communication des causes identifiées. Il peut être utilisé dans le cadre de recherche de cause d'un problème ou d'identification et gestion des risques lors de la mise en place d'un projet.

Ce diagramme se structure habituellement autour du concept des 5 M. Chaque branche reçoit d'autres causes ou catégories hiérarchisées selon leur niveau de détail. Le positionnement des causes met en évidence les causes les plus directes en les plaçant les plus proches de l'arête centrale. ↑ (en) Matthew A.

5 Whys - Problem Solving Skills from MindTools. Quickly Getting to the Root of a Problem How to use the 5 Whys technique, with James Manktelow & Amy Carlson.

The 5 Whys is a simple problem-solving technique that helps you to get to the root of a problem quickly. Determine The Root Cause: 5 Whys. Asking “Why?”

May be a favorite technique of your three year old child in driving you crazy, but it could teach you a valuable Six Sigma quality lesson. The 5 Whys is a technique used in the Analyze phase of the Six Sigma DMAIC (Define, Measure, Analyze, Improve, Control) methodology. It is a great Six Sigma tool that does not involve data segmentation, hypothesis testing, regression or other advanced statistical tools, and in many cases can be completed without a data collection plan.

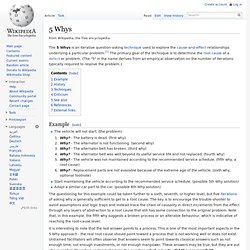

By repeatedly asking the question “Why” (five is a good rule of thumb), you can peel away the layers of symptoms which can lead to the root cause of a problem. Very often the ostensible reason for a problem will lead you to another question. 5 Whys. The 5 Whys is an iterative question-asking technique used to explore the cause-and-effect relationships underlying a particular problem.[1] The primary goal of the technique is to determine the root cause of a defect or problem.

(The "5" in the name derives from an empirical observation on the number of iterations typically required to resolve the problem.) Example[edit] The vehicle will not start. (the problem)Why? - The battery is dead. The questioning for this example could be taken further to a sixth, seventh, or higher level, but five iterations of asking why is generally sufficient to get to a root cause. It is interesting to note that the last answer points to a process. A key phrase to keep in mind in any 5 Why exercise is "people do not fail, processes do". History[edit] The technique was originally developed by Sakichi Toyoda and was used within the Toyota Motor Corporation during the evolution of its manufacturing methodologies. Techniques[edit] Criticism[edit] See also[edit] Rb.ec-lille.fr/l/Qualite/Qualite_Ishikawa.pdf. Www.iaat.org/telechargement/guide_methodo/2_2_5pourquoi.pdf.

Les 5 pourquoi. Le 5 pourquoi en questions De quoi s'agit-il ?

Cet outil consiste à se poser la question "Pourquoi ? " cinq fois de suite. Cette méthode a été créé par Sakichi Toyoda, le fondateur de Toyota. Dans quel contexte l'utiliser ? D'une façon générale, il peut s'utiliser dans n'importe quelle démarche de progrès. Pourquoi l'utiliser ? C'est sans doute l'outil le plus simple mais il est d'une efficacité redoutable. 5P, Méthode 5 Pourquoi ou Why-Why.