Links. Magazines we found helpful: Home Power magazine We feel it's the best magazine out there on solar living.

Books we found very informative and helpful: Earthbag Building: The Tools, Tricks and Techniques, by Kaki Hunter and Donald Kiffmeyer The Natural House, A Complete Guide to Healthy, Energy-Efficient, Environmental Homes, by Daniel D. Chiras. The Natural Plaster Book, earth, lime, and gypsum plasters for natural homes, by Cedar Rose Guelberth & Dan Chiras. Greenhouse Gardener's Companion, by Shane Smith. Do-It-Yourself Housebuilding, The Complete Handbook, by George Nash. The Solar Electric House, by Steven J.

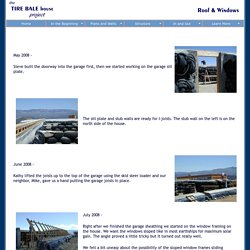

Roof and Windows. May 2008 - Steve built the doorway into the garage first, then we started working on the garage sill plate.

The sill plate and stub walls are ready for I-joists. The stub wall on the left is on the north side of the house. June 2008 - The Tire Bale house project. DEEP DRIP 14 in. Tree Watering Stake-GKDD014. TUMBLEWEED. DEEP DRIP 14 in. Tree Watering Stake-GKDD014. Naturally Beautiful Walls. Naturally Beautiful Walls. Naturally Beautiful Walls. Zurn - Ecovantage High Efficiency Toilets Two Piece Toilets Commercial Fixtures. Alpha Chemicals - Zinc Sulfate. How to guide ....... Oiling & waxing wooden floors. Plans for a Small "Starter" Straw Bale Home or Guest House. Thermalstar, a unit made in Canada which has come out recently, combines both the high output of "evacuated heat tubes" and a large gravity fed batch tank on the roof - It received an excellent review in Home Power Magazine, Issue 97.

Cost is about $700. WINDOWS/DOORS:"Kloss" system for best energy efficiency (all windows and doors are doubled with a horizontal mini-blind installed in the 5-6" air space left between them) FOUNDATION: trench filled with rubble (bits of concrete, stones, gravel), then built up with earth bags to make a small stem wall for the bales to rest on (see picture at right) - note that the bale walls are "pinned" with bamboo on the outside of the bales (this eliminates the need to use "all thread" up through the middle of the bales which is a pain to do and expensive) - for a complete description of rubble trench foundations, see "Mortgage Free! Ancient Finishes for Modern Distinction. Lime Plastering of Straw Bale Walls (Both Hand Applied and Professionally Shot) Clogging Somewhat more water than is used for traditional cement stucco was needed in order to keep the pumper/mixer and supply hose from clogging up.

Picture below -- grumbling stucco crew getting their pumper unclogged. Cracking We had some cracking as the stucco started to cure. This was easily repaired with a wet float sponge before the plaster was dry. A warm (but not hot) and humid environment is best to allow the stucco to cure slowly and not dry out too quickly. Apearance of Adobe Questions and Answers. Quentin Wilson and Associates, specializes in solar adobe design and construction.

He grew up in the South Valley of Albuquerque, New Mexico where he watched adobe bricks being made. In the fifth grade, he made miniature adobes on cookie sheets in his mother’s oven in order to construct house models for a class assignment. By age thirteen he made full-sized adobes in the back yard and ruined the grass. Later, he traveled a bit, went through the Army, and graduated eventually from the University of New Mexico with a major in physics, minors in math, chemistry, and education in 1970.

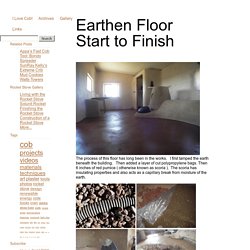

After teaching high school two years and community college math for three more, Quentin moved into professional solar adobe construction in 1976 as the Project Manager and Instructor for the Sundwellings Demonstration Project at Ghost Ranch, Abiquiu, NM. Q: I wish I could build my own Adobe home. A: I hate to be so smug, but we have dedicated our lives to doing the real thing. ∞ Earthen Floor Start to Finish. The process of this floor has long been in the works.

I first tamped the earth beneath the building. Then added a layer of cut polypropylene bags. Then 6 inches of red pumice ( otherwise known as scoria ). Down to Earth Design - online articles on natural building & sustainable design. Lime putty increases plasticity and workability the longer it is mixed.

I recommend mixing in a mortar mixer (not a cement mixer!) For at least 20-30 minutes. Alternate the addition of sand and putty so your ingredients mix thoroughly. You can add a small amount of water if your mix is extremely thick. The plaster should be stiff but should spread easily, like cream cheese. Note that lime is highly alkaline, and can severely burn your skin. To prepare your walls for lime plaster, first shape your walls exactly how you would like them to look once plastered.

When applying lime stucco over strawbale walls, I recommend 3 coats of lime directly on the strawbales. I do NOT recommend lime plaster over clay plasters for exteriors in wet climates. Be sure to wet your walls down well before applying each coat of lime plaster. Do not rework plaster once it has stuck to the wall, this pulls lime to the surface and leaves what is underneath sandy with less binder. Lime Works Ltd.