Water wheel pump. How the ram pump works. Pendulum eases pumping of water Williamson ram pump. WORLDS SIMPLEST WATER PUMP!! Make a PULSER PUMP! (with Captions) Build a Hydraulic Ram Pump - DIY. The search for a "perpetual motion" machine is just about as old as civilization itself.

And though we all know that such a gadget probably doesn't exist, there is a piece of equipment that comes pretty close: the hydraulic ram pump. The water ram (also known as a trompe) has been around for quite a while and was a widely used means of pumping water before electricity became common in rural areas. Strictly speaking, the ram pump doesn't create its own power but draws energy from the force of a moving column of water, usually fed through a pipe from a point more than 18 inches above the trompe. Although the hydro ram won't operate without a fluid power source, it will work indefinitely when water is present.

And, except for an adjustment every few months, the device requires no maintenance whatsoever! It's a Bargain at 1/10 the Price... Quality hydraulic rams are available commercially for anywhere from $400 to $800, complete. ...And Building It's a Snap The Possibilities Are Endless. Home-made Hydraulic Ram Pump. This information is provided as a service to those wanting to try to build their own hydraulic ram pump.

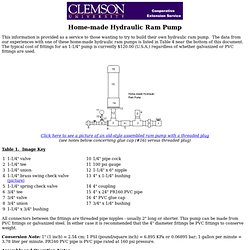

The data from our experiences with one of these home-made hydraulic ram pumps is listed in Table 4 near the bottom of this document. The typical cost of fittings for an 1-1/4" pump is currently $120.00 (U.S.A.) regardless of whether galvanized or PVC fittings are used. Table 1. Image Key All connectors between the fittings are threaded pipe nipples - usually 2" long or shorter. Conversion Note: 1" (1 inch) = 2.54 cm; 1 PSI (pound/square inch) = 6.895 KPa or 0.06895 bar; 1 gallon per minute = 3.78 liter per minute. Pressure Chamber - A bicycle or "scooter tire" inner tube is placed inside the pressure chamber (part 15) as an "air bladder" to prevent water-logging or air-logging.

Build your own solar-powered water pumping station by Jeffrey Yago, P.E., CEM. In the last issue, there was an excellent article by Dorothy Ainsworth on water pumping using mechanical windmills.

In this issue I will address another form of "free" water pumping. There are many remote applications where a solar-powered water pump is more cost effective than installing a conventional grid-connected AC pump. I recently designed a solar-powered pumping system for a local farmer wanting to pump water from a lake up to a watering trough for cattle in a distant fenced field. We have also designed larger systems to pump directly from drilled wells up to elevated storage tanks, which provide gravity-fed water back down to remote ranch buildings. Basic system description These solar applications made economic sense because the location was too remote to run a long power line.

By adding a storage tank and increasing the size of the pumping system, excess pumped water can be stored, which can continue to supply water during the night or when it's cloudy and the pump is off. Pulser pump. I give permission to reuse and adapt any and all pictures and animated gifs that I have produced in the past for this project.

Brian White, 3rd May 2010 Diagram of a Pulser Pump The pulser pump is a simple, water powered mechanical device, also known as a bubble pump. Components of this pump have been used for various purposes, including the extraction of oil or in refrigeration cycles. Heat driven bubble pumps are most common, but this particular design of a pulser pump using the turbulent flow in a stream to trap air has yet to become common. [edit] Background Information [edit] Overview The pulser pump is a combination of a trompe and an air lift pump. The pulser pump simply uses the trompe part to power the airlift part. [edit] Benefits As mentioned in the Introduction section, the main benefits of the pump are twofold. Secondly, the pulser pump has no moving components. [edit] History [edit] Principle of Operation.