Top 7 3D Printing Announcements at CES 2017. Though CES may stand for the Consumer Electronics Show, the event provides an interesting insight into the state of the industry, and some big industrial news does occur, at least from time to time.

For this reason, its worth paying close attention to the space that 3D printing occupies at CES every year. You never know just what innovations may spring up in Las Vegas. Metal X from Markforged The unveiling of the Metal X 3D printer by Markforged may have been the biggest 3D printing news from CES 2017. For less than $100,000 it will now be possible to 3D print complex metal parts with the Metal X.

The Metal X is capable of 3D printing all metal parts with closed, complex geometries. 3D Scanning Reflective Objects With Photogrammetry. By James Busby One question I see rising time and time again is “how do I scan shiny or reflective objects with photogrammetry” The answer is, you can't, it's impossible to scan a / transparent / reflective or very shiny objects using photogrammetry without some kind of surface preparation or complicated projection technique.

Photogrammetry works by defining exact positions of reference points on a given surface. So an object like the glass bowl we are going to use for this example will have little to no surface detail for the software to pick up on. Anything that is there will be confused by reflections and refractions within the surface of the glass. A few people have expressed the opinion that using a polarising filter on the camera lens will help in some way, whilst it will help to remove unwanted reflections the surface will still contain little or no detail and therefore will not scan well. So the first stage is to prepare the tools and equipment that you will need. Camera. Agisoft PhotoScan.

Home - CapturingReality.com. Autodesk ReMake. © 2015 Autodesk, Inc.

All rights reserved. All use of this Service is subject to the terms and conditions of the applicable Autodesk terms of service accepted upon access of this Service. This Service may incorporate or use background Autodesk technology components. For information about these components, click here: Trademarks Autodesk and the Autodesk logo are registered trademarks or trademarks of Autodesk, Inc., and/or its subsidiaries and/or affiliates.

All other brand names, product names or trademarks belong to their respective holders. Third-Party Software Credits and Attributions. Triplegangers Home page. Eora 3D. Curatio: World's First Dedicated 3D Hand Scanner. Project Overview 3D Scanning is an emerging field in technology.

From scanning ants to scanning cities, the possibilities seem endless. However, body parts are still very hard to scan due to their agile nature. A prior graduate designed a 3D printed brace, and during her process she experienced the frustrating process of trying to scan a hand properly. During my graduation, I developed the first dedicated and low-cost 3D Hand Scanner.

This model opens a new world of possibilities: think of 3D printed braces, personalized medical instruments and a long-awaited tool for everyone who designs products that interact with the human hand. Team Credits Johan Molenbroek, Yu Song, Pieter van der Zwan, Richard Garsthagen Project Images Project Details Technology Choice Most 3D Scanners are based on an optical technique, which enables flexibility, speed and precision. The Human Hand Consisting of 27 bones, the hand is one of the most flexible and precisely controlled parts of the human body. Student-Made Hand Scanner May Be a Breakthrough 3D Technology. In Brief Curatio, a 3D scanner developed by a student, allows users to map out areas with ease.

Curatio Despite advances in 3D technology, 3D scanning still has a lot of limitations. While it may be easy to scan whole objects, using existing technologies to try to map a specific part, like your own hand, would prove to be nearly impossible. DIY 3D Printer for Under $80! Technology is increasing at an exponential rate with new advancements being made everyday.

Since the introduction of 3D printers in 1983 by the inventor Chuck Hull, 3D technology has taken the world by storm. Advancements are being made in every area including 3D printed cars, houses, and even printed organs! Who knows what 3D printers will be capable of in the future. One thing is for certain though, 3D printers are EXPENSIVE. iSCAN – Expertise laser 3D inc. » Brekel. Real-time 3D Reconstruction at Scale using Voxel Hashing. Microsoft Develops App That Turns Any Smartphone Into a Comprehensive 3D Scanner. It seems like it was just yesterday that I first was introduced to 3D scanning as a desktop production method used for 3D printing, yet over the past two years or so, the technology has continued to evolve at rapid rates.

Just a few short years ago, it was rather expensive to purchase a machine capable of creating detailed 3-dimensional scans, and even some of the best consumer level 3D scanners were quite pitiful in capturing a quality 3D printable model. Fast forward to today, and there comes news from Microsoft Research Lab on a new smartphone application that might just turn the 3D scanning and printing spaces upside down. Called MobileFusion, the application can be installed on virtually any smartphone, and then used to create 3D printable models of any object without the need for any additional hardware. That’s right, the application uses only your smartphone’s camera and processor in order to generate 3-dimensional representations of objects. Mataerial. i3DConverter. 21 Ways That 3D Printing Changed The World In 2014. 1.

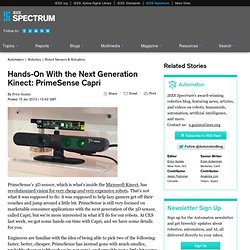

Shea’s New Hand A little girl asked for a hand for Christmas and the faculty and students at University of Wisconsin-Milwaukee made her wish come true. Watch the story here. Hands-On With the Next Generation Kinect: PrimeSense Capri. PrimeSense's 3D sensor, which is what's inside the Microsoft Kinect, has revolutionized vision for very cheap and very expensive robots.

That's not what it was supposed to do: it was supposed to help lazy gamers get off their couches and jump around a little bit. PrimeSense is still very focused on marketable consumer applications with the next generation of the 3D sensor, called Capri, but we're more interested in what it'll do for our robots. At CES last week, we got some hands-on time with Capri, and we have some details for you. Engineers are familiar with the idea of being able to pick two of the following: faster, better, cheaper. PrimeSense has instead gone with much smaller, probably cheaper (although we're not sure), and arguably just a little bit worse when it comes to performance. Field of View 57.5×45 Range 0.8m-3.5m VGA depth map (640×480) USB 2.0 powered Standard off the shelf components OpenNI compliant.