Health and Safety at Work etc Act 1974 – legislation explained. The Health and Safety at Work etc Act 1974 (also referred to as HSWA, the HSW Act, the 1974 Act or HASAWA) is the primary piece of legislation covering occupational health and safety in Great Britain.

The Health and Safety Executive, with local authorities (and other enforcing authorities) is responsible for enforcing the Act and a number of other Acts and Statutory Instruments relevant to the working environment. The full text of the Act (as amended) is available at legislation.gov.uk [1] where it can also be downloaded free of charge. Health and Safety at Work etc Act 1974 [2] This is the latest version. . [3] website. Statutory instruments are pieces of secondary legislation made under specific Acts of Parliament. See Legislation enforced by HSE[4] for more details.

If you need further advice on legal matters concerning the workplace, please consult Sources of information and external advisory services[5]. You can also seek independent legal advice. Reporting of Injuries, Diseases and Dangerous Occurrences Regulations 2013 - RIDDOR - HSE. Lifting Operations and Lifting Equipment Regulations 1998 (LOLER) - Work equipment and machinery. These Regulations (often abbreviated to LOLER) place duties on people and companies who own, operate or have control over lifting equipment.

This includes all businesses and organisations whose employees use lifting equipment, whether owned by them or not. In most cases, lifting equipment is also work equipment so the Provision and Use of Work Equipment Regulations (PUWER) will also apply (including inspection[1] and maintenance[2]). All lifting operations involving lifting equipment must be properly planned by a competent person, appropriately supervised and carried out in a safe manner. LOLER also requires that all equipment used for lifting is fit for purpose, appropriate for the task, suitably marked and, in many cases, subject to statutory periodic 'thorough examination[3]'. Records must be kept of all thorough examinations and any defects found must be reported to both the person responsible for the equipment and the relevant enforcing authority. What you should do. Reporting of Injuries, Diseases and Dangerous Occurrences Regulations 2013 - RIDDOR - HSE.

Provision and Use of Work Equipment Regulations 1998 (PUWER) - Work equipment and machinery. These Regulations, often abbreviated to PUWER, place duties on people and companies who own, operate or have control over work equipment.

PUWER also places responsibilities on businesses and organisations whose employees use work equipment, whether owned by them or not. PUWER requires that equipment provided for use at work is: suitable for the intended use safe for use, maintained in a safe condition and inspected to ensure it is correctly installed and does not subsequently deteriorate used only by people who have received adequate information, instruction and training accompanied by suitable health and safety measures, such as protective devices and controls.

Personnel Protective Equipment Leaflet. Personal Protective Equipment (PPE) Employers have duties concerning the provision and use of personal protective equipment (PPE) at work.

PPE is equipment that will protect the user against health or safety risks at work. It can include items such as safety helmets, gloves, eye protection, high-visibility clothing, safety footwear and safety harnesses. It also includes respiratory protective equipment (RPE). Why is PPE important? Making the workplace safe includes providing instructions, procedures, training and supervision to encourage people to work safely and responsibly. Control of Substances Hazardous to Health (COSHH) - COSHH. Hazard symbols and hazard pictograms - Chemical classification. Hazard pictograms alert us to the presence of a hazardous chemical.

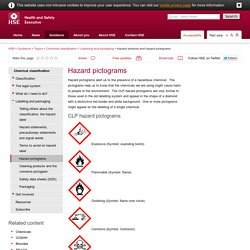

The pictograms help us to know that the chemicals we are using might cause harm to people or the environment. The CLP hazard pictograms are very similar to those used in the old labelling system and appear in the shape of a diamond with a distinctive red border and white background. One or more pictograms might appear on the labelling of a single chemical. Explosive (Symbol: exploding bomb) Flammable (Symbol: flame) Oxidising (Symbol: flame over circle) Corrosive (Symbol: Corrosion) Acute toxicity (Symbol: Skull and crossbones) Hazardous to the environment (Symbol: Dead tree and fish) You’ll see that the old 'harmful/irritant' symbol is missing.

Health hazard/Hazardous to the ozone layer (Symbol: Exclamation mark) A couple of new pictograms have also been introduced: