The Companies that Bring Us Knife Steel - Knife Steel Nerds. Thanks to AJ, Tobias Hangler, Benjamin Whitaker, Mike Latahm, Mike Pini, Jonathon Pye, Allan Benjamin, and Zaur for becoming Knife Steel Nerds Patreon supporters!

My new book Knife Engineering is now in stock at BladeHQ. Steel. Cedric and Ada Steel Comparison Ratings - Google Sheets. The Compound Bevel. Let's talk about Waterstones. 52100 steel?? AISI 1055 Knife Steel Composition Analysis Graph, Equivalents And Overview Version 4.36. Hudson Tool Steel allows users to compare the qualities and benefits associated with the different types of tool steel. Super Steels vs Regular Knife Steels - Knife Steel Nerds. Thanks to Daniel Jackson for becoming a Knife Steel Nerds Patreon supporter!

Super Steel I see frequent references to “super steel” online, and I was curious about how long that terminology has been around. I did searches on bladeforums as it is one of the oldest knife forums. The number of references to “super steel” has increased over time, but so have the number of posts on bladeforums. Edge Performance - Spyderco Forums. I carried and honed the factory edge for week or two until it wasn't responding to Spyderco white ceramic and stropping.

You know when it's time to hit the stones when the edge no longer comes up crisp after a few licks on the white ceramic and the stroping. Since I had to re-apex on the stone to get that crispy crispy edge it was also time to reprofile and remove the factory bevel scratches and get some fresh steel at the Apex. Spydercos 4v cut like butter on the CBN 400 grit resin stone. While Spyderco doesn't release the HRC data on their knives I've luckily had a lot of experience with 4v at different hardnesses from 64hrc to 67hrc and there are some unique little quirks you pick up on the material as a sharpener It's definitely closer to the 60-62hrc side. However, that was a misunderstanding of what the spec sheet shows for as quenched hardness values for different Austenizing tempetures.

Best Knife Steel Comparison - Steel Charts & Guide. Story of RWL34™ - Damasteel® RWL34™ is named after the world famous knife maker Robert W Loveless, January 2, 1929 – September 2, 2010.

Bob Loveless or RW Loveless was an American knife maker who designed and popularized the hollow ground drop point blade and the use of full tapered tangs and screw-type handle scale fasteners within the art of knife making. He is cited by other knife makers and collectors as one of the most innovative custom knife makers in the world. Bob discovered the use of the Japanese made ball bearing steel ATS34 from Kobe Steel as best suited for his high demands for a stainless hardenable knife steel. Pelle Billgren the founder of Damasteel® was in search for the best stainless knife steels and learnt what Bob had discovered. Pelle was able to transform the already good ATS34 into a superior Powder Metallurgy made steel. Damasteel® was the first in the world to produce a powder metallurgy version of the ATS34 named RWL34™ after Bob Loveless. Making a DIY Knife with Denim Handle Scales. If you've read some of our previous knife reviews, such as the TOPS Hazen Legion 6.0 and the White River Firecraft FC5, you'll probably recognize the word micarta.

This term refers to a composite material that's often used on knife handles and gun grips. Some types of micarta have a marbled appearance with light and dark layers, while others appear as a single solid color. Micarta is also known for its ability to absorb moisture, so it can provide a secure grip even if your hands are wet or sweaty. So, what exactly is this material? Micarta is technically a brand name and registered trademark of Norplex-Micarta, but much like Kleenex tissues and the Thermos insulated water bottle, it has sometimes been used in a generic sense to describe a category of composites. In the following video, YouTube channel M.N. G10.lt Custom Made Scales. 1.

How to order custom scale/s? You can order via email only. Please email me what scale/s design you would like to order (logos or personal artworks to add graphic/inlays), what kind of material, information on clip positions, backspacer. 2. What knives do you make scales for? Benchmade Blade Steels. A.G.'s Stainless Steel Chart. Guide to the Best Knife Steel.

In choosing the best pocket knife you should pay particular attention to the type of steel used in the blade.

Alongside edge geometry and design, blade steel is a critical element that determines how a knife performs. Steel is essentially an alloy (i.e. a mix) of carbon and iron that is often enriched with other elements to improve certain characteristics depending on the desired application. In the knife industry different types of steel are created by varying the types of additive elements as well as how the blade is rolled and heated (i.e. the finishing process).

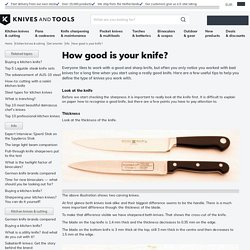

How good is your knife? Everyone likes to work with a good and sharp knife, but often you only notice you worked with bad knives for a long time when you start using a really good knife.

Here are a few useful tips to help you define the type of knives you work with. Behind the edge database! - Spyderco Forums. I would like to see a thread like this grow and have lots of measurements from all the common models, and if several people participate we can create averages to compensate for tolerances and perhaps even see if some sprints are ran thinner than others.

I will update this list as info is given, then start to average numbers as we get enough data. For consistency please try to stick to the measurement points that Sharp Guy outlined in post #17 below. Please only submit measurements taken from factory edged knives. PLEASE MEASURE AND FORMAT AS SEEN IN THIS POSTviewtopic.php? P=1130365#p1130365 Updated 3/28/2020 Behind Edge / Spine / Blade Stock Advocate - .023 / .116 / .117 Baby Horn Sprint - .014 / .080 / .090 Bradley Junction: 0.097” thick stock / 0.020” BTE,

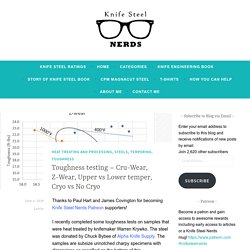

Toughness testing - Cru-Wear, Z-Wear, Upper vs Lower temper, Cryo vs No Cryo - Knife Steel Nerds. Thanks to Paul Hart and James Covington for becoming Knife Steel Nerds Patreon supporters!

I recently completed some toughness tests on samples that were heat treated by knifemaker Warren Krywko. The steel was donated by Chuck Bybee of Alpha Knife Supply. The samples are subsize unnotched charpy specimens with dimensions as specified on the bottom of this page: If we can get more people to make toughness specimens we can have more comparisons between steels, hardness points, heat treatment parameters, etc. Patreon dollars are for the purpose of paying for machining, shipping, testing, etc. for tests like toughness and CATRA edge retention, so if you are able to contribute that way please visit the Knife Steel Nerds Patreon page.

All About AEB-L - Knife Steel Nerds. Thanks to anteck7 and Aaron Lee for becoming Knife Steel Nerds Patreon supporters! History of AEB-L and 13C26 Tracking down the history of AEB-L was surprisingly difficult. The Uddeholm website claims that AEB-L was patented in 1928 [1]; however, that is not entirely truthful. Burrfection Store. My Top 5 Best Performing Knives. S110V vs S90V - Spyderco Forums. KevinOubre wrote:In my experience, there is no appreciable difference between S110V and S90V. On paper S110V has more carbide and thus higher corrosion resistance, but in practice with a pocket knife, you would have to cut an astronomical amount or material to see a functional difference. I assume you means higher wear resistance there, but quite frankly the difference between S110V and S90V in that respect is smaller than the compositional variances, let alone the process variation and this doesn't even factor in the random/systematic errors that are going to come into play in hand comparison cutting on non-standard materials.

It simply isn't possible, anyone who is claiming to see that difference is just showing confirmation bias, the math is high school statistics. Imagine if I give you a normal bathroom scale which measures +/- 0.5 lbs or so and I lay 10 glasses in front of you and tell you that five of them contain 1000 grains of sand and 5 contain 900 grains of sand. SJ can't polish S110V. Spyderco Manix 2 – S110V Review – Belgian Sharpening. First of all, I’d like to apologize for the lack of new articles here and on other media.

The past year has been crazy with traveling and new things in my personal life that caused me to write less than I wanted to. I recently received a Spyderco Manix 2 in S110V to try out the steel. According to online reviews, video’s and social media posts, this is one of the better knife steels used by Spyderco lately. I know online reviews don’t always mirror real world usage, so I’d try it out myself. What is CPM S110V? In short, this is a pretty new high wear resistance stainless tool steel from Crucible. This addition makes for very hard, fine carbides. Out of the box Spyderco’s edges out of the box have always been shaving sharp power buffed edges… That is until recently. Mine was sharp out of the box, but had serious grind issues.

On top of that, the heel was over ground with a steeper edge that the rest of the blade and there was black crud in the pivot and lock area. Sharpening The results: