Nikolay Shelepov

Guerrilla guide to CNC machining and resin casting, volume I. Table of contents: 1.

Introduction A quick overview of what this guide has to offer to DIYers looking for a CNC mill - and to those who have already settled on low-cost 3D printing or any other rapid prototyping technology out there. 2. Setting up a CNC mill Pointers for selecting a low-cost, hobbyist-friendly CNC mill, stocking up on tools, and keeping the whole setup in great condition for many years to come. 3. HeeksCNC « The Hell Ya Beller. HeeksCNC can be finicky about profiles.

Often I've found that a sketch which should be easily profiled won't generate any gcode at all. When I look in the console, I find an error like this File "/usr/lib/heekscnc/kurve_funcs.py", line 247, in profile raise Exception, "couldn't offset kurve " + str(offset_curve)Exception: couldn't offset kurve <area.Curve object at 0xb6f4bf2c> It most often happens when profiling inside a closed sketch where the radii is close to the diameter of the cutter. Sometimes I can get around it by changing from climb to conventional milling or vice versa. Recently I was profiling several cutouts that were exact copies of one another just rotated around a central point. It seems that the error is coming from the entry point. This won't work in every case, especially if the pocket is very close to the size of the cutter or made up of tight curves but for the most common cases it should work fine.

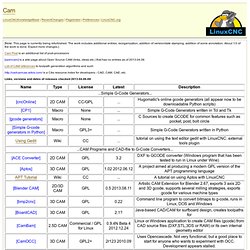

Guerrilla guide to CNC machining and resin casting, volume II. EMC Documentation Wiki: Cam. [Note: This page is currently being refurbished.

The work includes additional entries, reorganization, addition of version/date stamping, addition of some annotation. About 1/3 of the work is done. Expect more changes.] Cam Post is an additional list of post-processors [opencam] is a wiki page about Open Source CAM (links, ideas etc.) that has no entries as of 2013.04.06 List of CAM references to toolpath generation algorithms and such is a CAx resource index for developers - CAD, CAM, CAE, etc. Links, versions and dates of releases checked 2013.04.06-08 CAD programs for Linux: programs to run windows software under linux: note: a few of the links are copied from. FreeMILL, Free CAM software - Rhinoceros - Related Products and Services. EMC Documentation Wiki: Cam. Homemade CNC Router The Builder's Guide (FREE!) This guide is still under construction!

Sections Introduction My Experience About Kits and Plans About This Guide The Guide Starts Here IntroductionSo you've decided to build a homemade CNC router or maybe youre just considering it, but where do you start? There are many advantages to owning a CNC router. Homemade CNC routers can cut and carve almost anything. For any hobbyist or DIYer, this opens many doors. Yes, you can build a CNC router that is just about as good as any other for a fraction of the retail price, and its not that difficult! There is also a great deal of flexibility when you design and build your own machine. There are many reasons people want to build their own homemade CNC router. My Experience When I first started to design and build my first homemade CNC router, I had it all figured out in about a day.

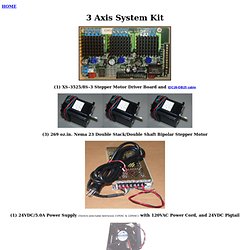

Do I really need ball screws or will ACME screws work fine? Luckily, some of my questions I could answer with my mechanical engineering background. 3 Axis System Kit. 3 Axis System Kit (1) XS-3525/8S-3 Stepper Motor Driver Board and IDC26-DB25 cable (3) 269 oz.in.

Nema 23 Double Stack/Double Shaft Bipolar Stepper Motor (1) 24VDC/5.0A Power Supply (Switch selectable betrween 110VAC & 220VAC) with 120VAC Power Cord, and 24VDC Pigtail. 3 Axis System Kit. CNC Router Plans: Download free CNC router plans. CNC router plans are a great starting point for anyone wanting to build a CNC router.

They give valuable insight on how these machines work. Many of us are very visual people and it helps to see examples of these machines laid out on paper. Some plans are thorough enough to act as a complete blueprint from start to finish while others only offer bits of information. You may prefer to design and build your own machine. However, CNC router plans can still be a valuable resource. This is why we want to provide you with as many free plans and blueprints as possible. Even if you decide to use plans, we strongly suggest you read through the Builders Guide There you will find in depth information regarding all the components and their function.

For now, feel free to check out the plans below. Tweakie.CNC - CNC Homebuilt router, mill, engraver, vinyl cutter, hobby ... Tutorials. Machine axis load problems, ballscrew load, bearings bad, ways binding, gib friction, oil lubrication load troubleshooting. Vectric - CNC Software Solutions - Wood Carving - Engraving - Signmaking - Routing - Machining.

Vectric - CNC Software Solutions - Wood Carving - Engraving - Signmaking - Routing - Machining.